what equipments are used in the production of bentonite

Time:12 September 2025

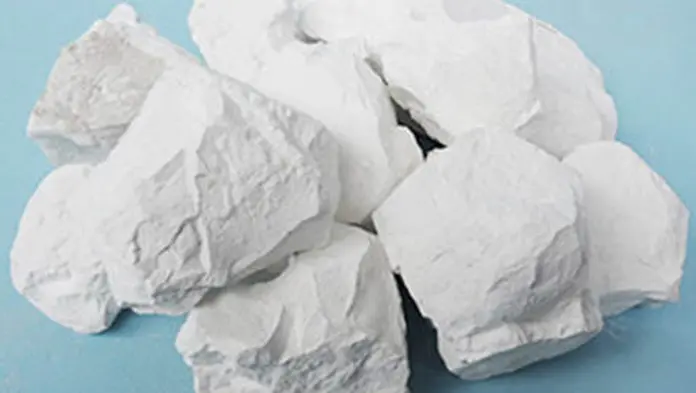

Bentonite is a naturally occurring clay that has a wide range of industrial applications, including drilling fluids, binders, and absorbents. The production of bentonite involves several processes and requires a variety of equipment to ensure efficient and high-quality output. This article provides a comprehensive overview of the equipment used in the production of bentonite.

1. Extraction Equipment

The first step in bentonite production is the extraction of raw bentonite from the earth. This process involves:

- Excavators: Used for digging and removing large quantities of bentonite from the ground.

- Bulldozers: Employed to clear the overburden and expose the bentonite deposits.

- Loaders: Facilitate the transportation of raw bentonite to the processing area.

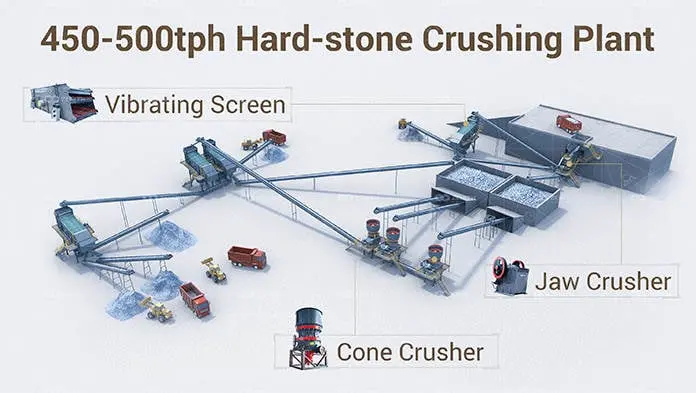

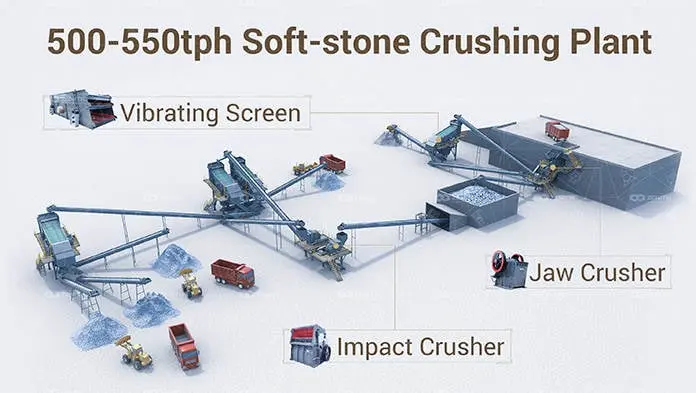

2. Crushing and Grinding Equipment

Once extracted, the raw bentonite needs to be processed to achieve the desired particle size:

- Jaw Crushers: Used to break down large chunks of bentonite into smaller pieces.

- Hammer Mills: Employed for further reduction of particle size by impact.

- Ball Mills: Provide fine grinding and ensure uniform particle size distribution.

3. Drying Equipment

Bentonite often contains moisture that must be removed to improve its quality and usability:

- Rotary Dryers: Utilize a rotating drum to dry bentonite by passing hot air through the material.

- Fluid Bed Dryers: Use a stream of hot air to fluidize and dry the bentonite particles efficiently.

4. Screening and Classification Equipment

To ensure uniformity and quality, bentonite is screened and classified:

- Vibrating Screens: Separate particles based on size using vibration.

- Cyclones: Classify particles based on their size and density using centrifugal forces.

5. Mixing and Blending Equipment

For certain applications, bentonite needs to be mixed with other materials:

- Pug Mills: Mix bentonite with water or other additives to achieve a homogeneous mixture.

- Ribbon Blenders: Provide thorough mixing of bentonite with other dry ingredients.

6. Packaging Equipment

Finally, processed bentonite must be packaged for distribution:

- Bagging Machines: Automatically fill and seal bags with processed bentonite.

- Palletizers: Stack and organize bags on pallets for efficient storage and transportation.

7. Quality Control Equipment

Ensuring the quality of bentonite is crucial for its industrial applications:

- Moisture Analyzers: Measure the moisture content of bentonite to ensure it meets specifications.

- Particle Size Analyzers: Determine the particle size distribution to maintain consistency.

Conclusion

The production of bentonite involves a series of processes that require specialized equipment to ensure efficiency and quality. From extraction to packaging, each stage utilizes specific machinery designed to handle the unique properties of bentonite. Understanding the role of each piece of equipment is essential for optimizing production and meeting industry standards.