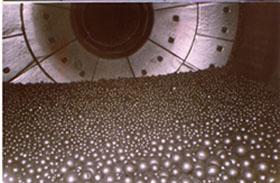

Steel Grinding Balls

Gulin steel grinding media for ball mills, pulverizers and attritors is cold forged and ground. The hardened steel balls (shots, beads) are available in different hardness, as required, in both high carbon steel and chrome alloy steel. For specific applications, stainless steel media and balls are also used for grinding and milling.

These ball mills are suggested for applications wherein metal /iron contamination is permissible. The main difference between steel ball mill & porcelain ball mill is the difference in grinding media used.

Steel Ball Mill for crushing and grinding process

Alloy steel media is particularly suitable, because of its high relative density and hardness, for crushing and mixing heavy and hard materials. Also where high pressure and impact grinding or crushing methods are employed. The forged steel media balls also find advantage in reducing particle size and fine dispersion of highly viscous fluids.

The steel shots, balls and beads – ball mill media – are preferred for contamination free and speedy (dry / wet) milling, grinding of solids, liquids dispersion and fine particle size reduction, homogenization of fillers and raw materials, attrition and pulverizing applications in ball, vibro, dyno, pearl, bead, pebble, attritor and small-media mills, vertical or horizontal.

Material Charge of Steel Ball Mill

The volume of paste charge is dependent upon ball loading, speed of the mill, and the ease with which gases are removed from the pigment. The above chart shows typical paste charges based on 33 1/3% ball charge and mill speed at 50% of critical (Nc). With these conditions, paste capacity can range from a low of 14% to a high of 45% of theoretical total volume.

Steel Ball Mill Charge

Selection is dependent upon the length of time for the dispersion, the maximum permissible temperature, the range of batch sizes to be produced and the end product quality. Above chart shows weights and volumes for a ball charge of 33013% total mill volume. SBM will gladly recommend the best combination of all factors to provide the most economical production 01 your particular product.