What is the best crusher for sandstone

Time:23 September 2025

Sandstone is a popular building material known for its durability and aesthetic appeal. Choosing the right crusher for sandstone is crucial to ensure efficient processing and optimal results. This article explores the best crushers for sandstone, considering various factors such as material properties, production requirements, and cost-effectiveness.

Understanding Sandstone Properties

Before selecting a crusher, it’s essential to understand the properties of sandstone:

- Composition: Sandstone is primarily composed of sand-sized mineral particles, mainly quartz and feldspar.

- Texture: It can range from fine to coarse-grained textures.

- Durability: Sandstone is relatively soft compared to other stones, which affects the type of crusher needed.

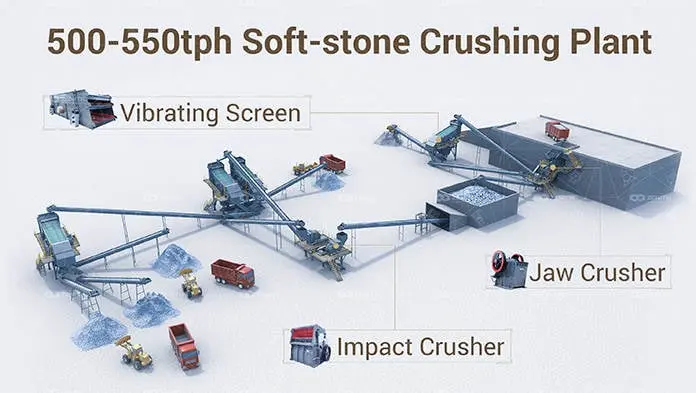

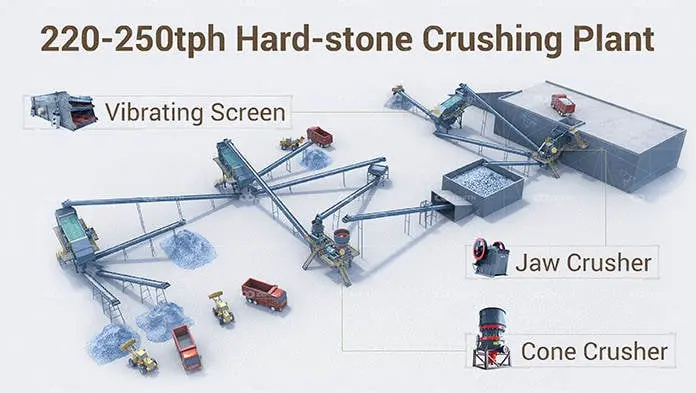

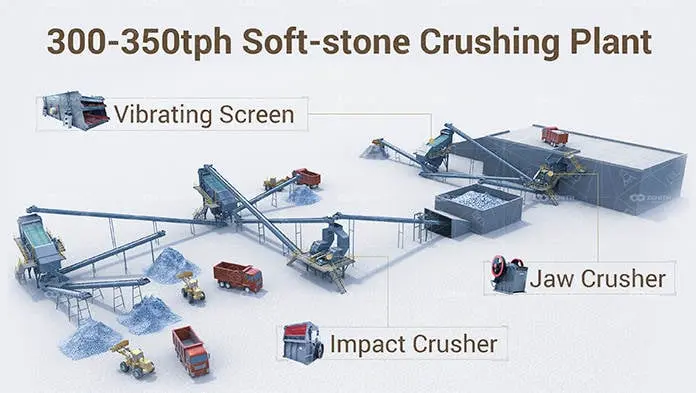

Types of Crushers for Sandstone

Several types of crushers can be used to process sandstone. Each type has its advantages and is suited for specific applications:

1. Jaw Crushers

Jaw crushers are commonly used for primary crushing. They are suitable for processing large blocks of sandstone.

– High capacity and efficiency

– Suitable for hard and abrasive materials

– Not ideal for producing fine-grained material

2. Impact Crushers

Impact crushers are used for secondary crushing and are effective for producing finer materials.

– Produces a more uniform particle size

– Good for softer materials like sandstone

– Higher wear and tear compared to jaw crushers

3. Cone Crushers

Cone crushers are versatile and can be used for both primary and secondary crushing.

– High production capacity

– Suitable for medium to hard materials

– More complex machinery, requiring skilled operation

4. Hammer Crushers

Hammer crushers are ideal for producing fine-grained materials from sandstone.

– Simple structure and easy maintenance

– Effective for soft to medium-hard materials

– Not suitable for very hard materials

Factors to Consider When Choosing a Crusher

Selecting the best crusher for sandstone involves considering several factors:

Material Characteristics

- Hardness: Softer materials like sandstone require crushers that minimize wear and tear.

- Moisture Content: High moisture content can affect crusher performance.

Production Requirements

- Capacity: Determine the required production capacity to choose an appropriately sized crusher.

- Particle Size: Consider the desired output size to select the right type of crusher.

Cost-Effectiveness

- Initial Investment: Evaluate the cost of purchasing and installing the crusher.

- Operating Costs: Consider maintenance, energy consumption, and wear parts replacement.

Conclusion

Choosing the best crusher for sandstone depends on the specific requirements of your project. Jaw crushers are ideal for primary crushing, while impact crushers and hammer crushers are better suited for producing finer materials. Cone crushers offer versatility for various applications. By understanding the properties of sandstone and considering factors like material characteristics, production requirements, and cost-effectiveness, you can select the most suitable crusher for your needs.