Hammer crusher Application

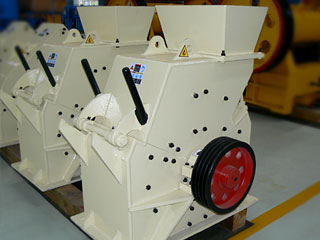

Hammer crusher

This series of new European-style Hammer crusher is widely used in metallurgy, mine, chemical, cement, coal dry stone, construction, sand making, refractory materials and ceramic industries. Used for secondary crusher or tertiary crushing, it mainly suitable for crushing various ores the compressive strength of which is no more than 320MPa. Gulin is independent research and development with high-tech of the hammers crusher and provides hydraulic hammer for sale.

Structure and Working Principle

Hydraulic hammers crusher is composed mainly by the frame, rotor, impact iron bar, grid bar and other components. The frame consists of upper and lower parts, which are welded together after cutting by a steel plate, the remaining parts connected into a whole by bolts. There is high manganese steel liner inside the frame to facilitate replacement after worn. There are array of regularly distributed hammer bars on the spindle, which composed rotor together with rotary table and the shafts through the bar. The spindle is driven by the motor and V-belt, which promotes the rotor to rotate Centrifugal force produced when rotation makes the hammer stretch around. When the big materials get into the crushing cavity, they are crushed by the high-speed rotating hammers, the crushed products which meet the required size can be discharged from the sieve plate and become the final products, the products with larger size are brought back to the crushed area for being re-crushed, hit by a hammer and iron bar repeatedly, until they reach the required size. To avoid clogging, the water content of crushed material is generally not more than 20%.

Hammer crusher Features

- High productive capacity and big crushing ratio.

- Low power consumption and evenly granularity product.

- Simple, well knit and handy mechanical structure.

- Low investment costs and convenient management.

Hammers Crusher Performance Parameters

| Type | PC4008-75 | PC4012-90 | PC4015-132 |

|---|---|---|---|

| Dia. Of rotor /mm | 750 | 900 | 1150 |

| Rotor Length/ mm | 800 | 1200 | 1500 |

| Rotor speed r/min | 800-1000 | 800-1000 | 800-1000 |

| Max feeding size/mm | <100 | <100 | <100 |

| Discharged size/mm | 0-3 | 0-3 | 0-3 |

| Capacity t/h | 35-50 | 50-70 | 70-100 |

| Power of motor/kw | 55-75 | 75-90 | 110-132 |

| Number of hammer | 10 | 16 | 24 |

| Overall dimension L*W*H/mm | 1800*1650*1800 | 2200*2100*2200 | 2860*2500*2500 |

Note:The final size of Hammer crusher can be adjusted according to the customer request. This parameter is just for reference. If any change of the specification, it should be in accordance with company’s actual product.