What are the advantages of different types of rock crushers

Time:29 September 2025

Rock crushers are essential equipment in the mining and construction industries. They are used to break down rocks into smaller, more manageable pieces. There are several types of rock crushers, each with its own advantages. Understanding these benefits can help in selecting the right crusher for specific applications.

Types of Rock Crushers

Before diving into the advantages, it’s important to understand the different types of rock crushers available:

- Jaw Crushers

- Cone Crushers

- Impact Crushers

- Hammer Crushers

- Gyratory Crushers

Advantages of Jaw Crushers

Jaw crushers are one of the most commonly used crushers due to their simplicity and effectiveness.

- High Efficiency: Jaw crushers have a high crushing ratio, meaning they can process large amounts of material quickly.

- Versatility: Suitable for various materials, including hard and abrasive rocks.

- Durability: Built with robust materials to withstand heavy-duty operations.

- Ease of Maintenance: Simple design makes them easier to maintain and repair.

Advantages of Cone Crushers

Cone crushers are popular for secondary and tertiary crushing stages.

- Precision: Provides precise control over the size and shape of the final product.

- Consistency: Produces uniform-sized aggregates, ideal for specific construction needs.

- Energy Efficiency: Consumes less energy compared to other types of crushers.

- Low Operating Costs: Designed for long-term use with minimal maintenance requirements.

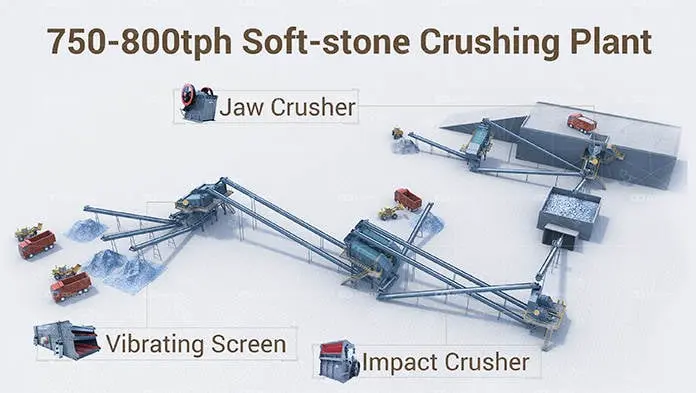

Advantages of Impact Crushers

Impact crushers are ideal for processing softer materials and recycling applications.

- High Reduction Ratio: Capable of producing smaller-sized products in a single pass.

- Flexibility: Can handle a variety of materials, including concrete and asphalt.

- Improved Product Quality: Produces cubical-shaped aggregates, enhancing the quality of the final product.

- Versatile Applications: Suitable for both primary and secondary crushing.

Advantages of Hammer Crushers

Hammer crushers are known for their simplicity and effectiveness in crushing softer materials.

- Cost-Effective: Generally cheaper than other types of crushers.

- Simple Design: Easy to operate and maintain.

- High Production Capacity: Capable of processing large volumes of material quickly.

- Adaptability: Can be used in various applications, including mining and recycling.

Advantages of Gyratory Crushers

Gyratory crushers are primarily used for large-scale crushing operations.

- High Capacity: Designed to handle large volumes of material efficiently.

- Continuous Operation: Capable of continuous operation, reducing downtime.

- Uniform Product Size: Produces consistent product sizes, ideal for large projects.

- Durability: Built to withstand harsh conditions and heavy loads.

Conclusion

Choosing the right rock crusher depends on the specific needs of the project. Each type of crusher has its own set of advantages that make it suitable for particular applications. Understanding these benefits can help in selecting the most efficient and cost-effective solution for crushing operations. Whether you need high efficiency, precision, or versatility, there is a rock crusher that can meet your requirements.