What crusher produces rock in limestone

Time:12 September 2025

Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃). It is widely used in construction, agriculture, and various industries. To utilize limestone effectively, it must be crushed into smaller, manageable pieces. This article explores the types of crushers that are commonly used to produce rock from limestone.

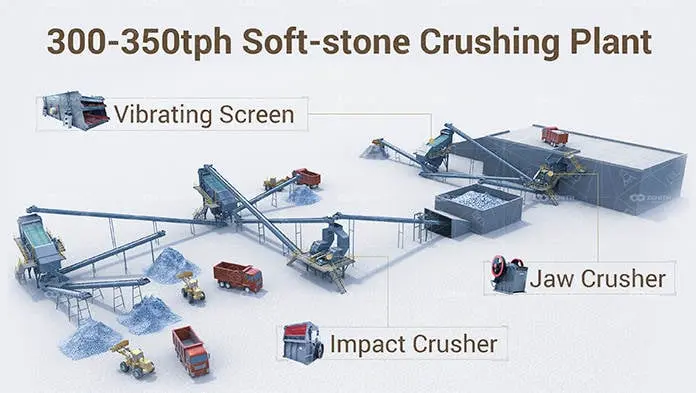

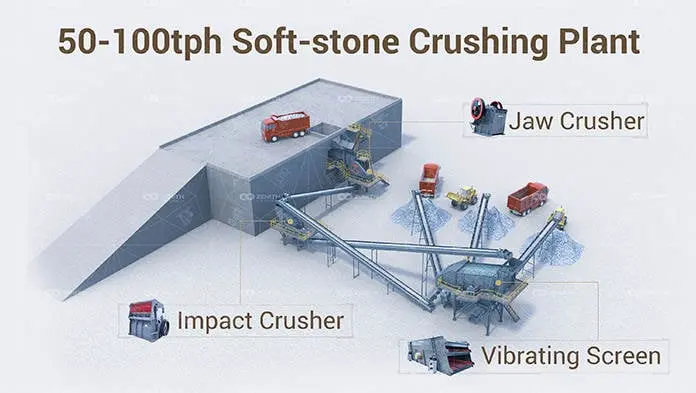

Types of Crushers Used for Limestone

Several types of crushers are employed to crush limestone, each with its unique mechanism and application. Below are the most common types:

1. Jaw Crushers

Jaw crushers are primary crushers that utilize compressive force to break down large limestone rocks. They are characterized by:

- A fixed jaw and a moving jaw that create a V-shaped chamber.

- The ability to handle large feed sizes.

- High efficiency in producing uniform-sized output.

2. Impact Crushers

Impact crushers use impact force to crush limestone. They are suitable for:

- Producing finely crushed limestone.

- Handling medium to soft limestone.

- Applications where the shape of the output is important.

3. Cone Crushers

Cone crushers are secondary crushers that crush limestone by squeezing it between a gyrating spindle and an enclosing concave hopper. Key features include:

- High capacity and efficiency.

- Ability to produce uniform-sized aggregates.

- Suitable for medium to hard limestone.

4. Hammer Crushers

Hammer crushers utilize high-speed rotating hammers to impact and break down limestone. They are ideal for:

- Producing smaller limestone particles.

- Applications requiring high reduction ratios.

- Crushing softer limestone varieties.

Factors Influencing Crusher Selection

Selecting the appropriate crusher for limestone involves considering several factors:

1. Limestone Hardness

- Soft limestone can be effectively crushed using impact or hammer crushers.

- Hard limestone may require jaw or cone crushers for efficient processing.

2. Desired Output Size

- Jaw crushers are ideal for larger output sizes.

- Impact and hammer crushers are preferred for finer outputs.

3. Production Capacity

- Cone crushers offer high capacity and are suitable for large-scale operations.

- Jaw crushers are also capable of handling high volumes.

4. Cost Considerations

- Hammer crushers are typically more cost-effective for smaller operations.

- Cone crushers may involve higher initial investment but offer long-term savings in large-scale applications.

Applications of Crushed Limestone

Crushed limestone has various applications, including:

- Construction: Used as aggregate in concrete and asphalt.

- Agriculture: Acts as a soil conditioner to neutralize acidic soils.

- Industrial: Serves as a raw material in cement production and steel manufacturing.

Conclusion

Choosing the right crusher for limestone is crucial for efficient processing and maximizing the material’s utility. By understanding the types of crushers available and the factors influencing their selection, industries can optimize their operations and achieve desired outcomes. Whether for construction, agriculture, or industrial use, crushed limestone remains an essential resource, and the right crusher ensures its effective production.