What equipment can be used to crush 6 mm aggregate into dust

Time:12 September 2025

Crushing aggregate into finer particles, such as dust, is a common requirement in various industries, including construction, mining, and recycling. This article explores the equipment options available for crushing 6 mm aggregate into dust, detailing their features, advantages, and operational considerations.

Types of Crushing Equipment

Several types of crushing equipment can be employed to reduce 6 mm aggregate into dust. Each type has its unique mechanism and suitability depending on the specific requirements of the task.

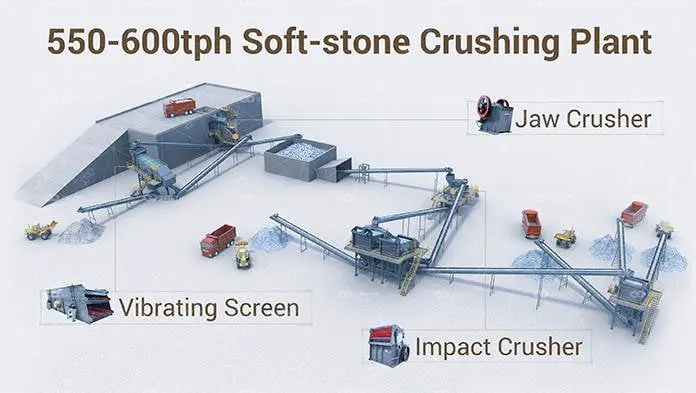

1. Jaw Crushers

Jaw crushers are primarily used for primary crushing. They are effective for breaking down large, hard materials into smaller, manageable pieces.

- Mechanism: Uses compressive force to crush materials between two plates (jaws).

- Advantages:

– High capacity and efficiency.

– Suitable for hard and abrasive materials.

– Not ideal for producing very fine particles or dust.

2. Cone Crushers

Cone crushers are suitable for secondary, tertiary, and quaternary crushing stages.

- Mechanism: Material is crushed by compressive forces between a stationary piece and a moving piece.

- Advantages:

– Produces finer particles than jaw crushers.

– Adjustable settings for different sizes.

– Requires consistent feed for optimal performance.

3. Impact Crushers

Impact crushers are used for producing finer particles and are ideal for softer materials.

- Mechanism: Material is shattered by high-speed impact with blow bars or hammers.

- Advantages:

– Produces uniform particle sizes.

– Effective for softer and less abrasive materials.

– Wear and tear can be significant with harder materials.

4. Hammer Mills

Hammer mills are versatile machines used for various crushing applications.

- Mechanism: Uses rotating hammers to crush material against a stationary surface.

- Advantages:

– Capable of producing very fine particles.

– Suitable for both hard and soft materials.

– High wear rate on hammers and screens.

5. Vertical Shaft Impactors (VSI)

VSIs are specialized for producing fine particles and are often used in the final stage of crushing.

- Mechanism: Material is accelerated by a rotor and thrown against a hard surface.

- Advantages:

– Excellent for producing fine and uniform particles.

– High reduction ratios.

– Energy-intensive and requires careful maintenance.

Factors to Consider When Choosing Equipment

Selecting the right equipment for crushing 6 mm aggregate into dust involves evaluating several factors:

- Material Characteristics: Hardness, abrasiveness, and moisture content of the aggregate.

- Desired Output: Specific particle size and distribution required.

- Capacity Requirements: Volume of material to be processed.

- Operational Costs: Energy consumption, maintenance, and wear parts.

- Space and Mobility: Available space and need for portability.

Conclusion

Crushing 6 mm aggregate into dust requires careful selection of equipment based on the material properties and desired output. Jaw crushers, cone crushers, impact crushers, hammer mills, and vertical shaft impactors each offer unique benefits and challenges. By understanding the capabilities and limitations of each type, operators can choose the most suitable equipment for their specific needs, ensuring efficient and cost-effective operations.