What is a cone-type rock crusher

Time:12 September 2025

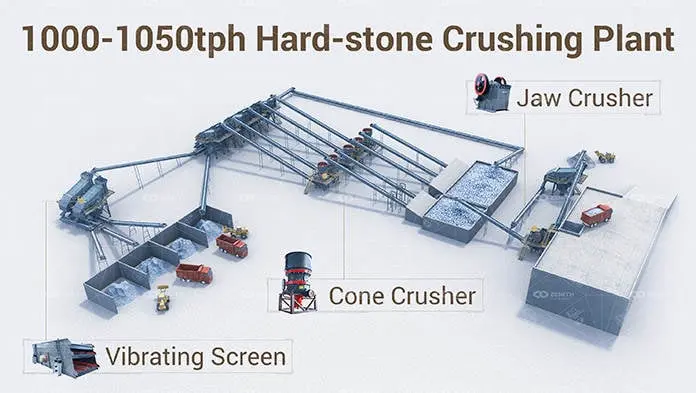

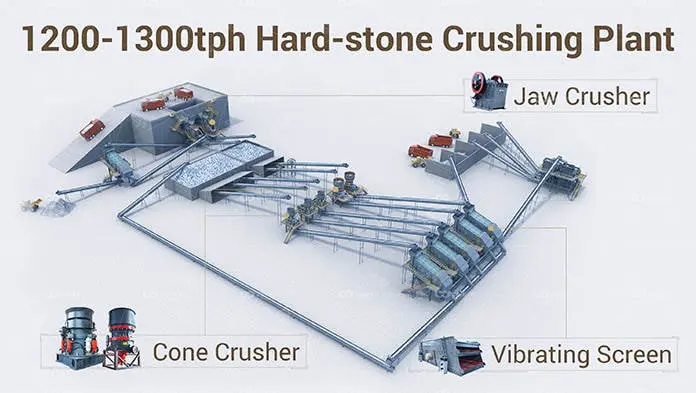

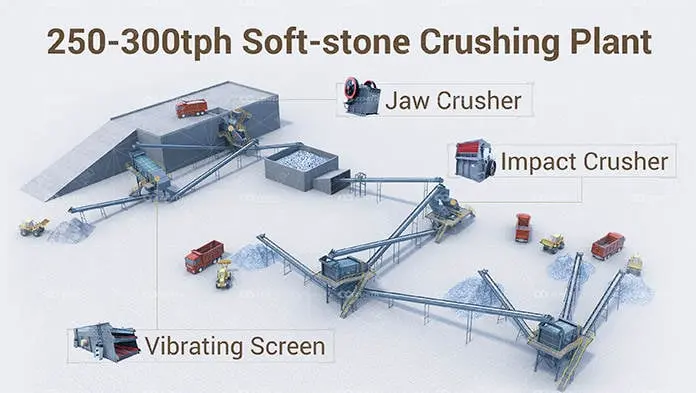

A cone-type rock crusher, often referred to as a cone crusher, is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. It is primarily used in mining, construction, and aggregate industries to crush materials into a more manageable size for further processing or use.

How Cone Crushers Work

Cone crushers operate by using a rotating piece of steel, the mantle, which gyrates within a stationary piece of steel, the concave. The rock is crushed between the mantle and the concave as the mantle moves closer and away from the concave in a continuous cycle.

Key Components

- Mantle: The moving part that crushes the rock.

- Concave: The stationary part that forms the outer surface of the crushing cavity.

- Eccentric Shaft: Provides the gyratory motion to the mantle.

- Hydraulic System: Used for adjusting the crusher settings and clearing blockages.

- Feed Hopper: Where the raw material is fed into the crusher.

Types of Cone Crushers

Cone crushers are categorized based on their crushing chamber design and the way they apply force to the rock. The main types include:

1. Standard Cone Crusher

– Used for secondary crushing.

– Produces a more cubical product.

– Suitable for medium to hard materials.

2. Short Head Cone Crusher

– Used for tertiary or quaternary crushing.

– Produces finer material.

– Ideal for finer applications.

3. Gyratory Cone Crusher

– Similar to a gyratory crusher but with a steeper cone angle.

– Used for primary crushing.

– Handles larger feed sizes.

Advantages of Cone Crushers

Cone crushers offer several advantages over other types of crushers:

- High Efficiency: Due to their design, cone crushers can crush materials more efficiently than jaw crushers.

- Uniform Product Size: They produce a more uniform product size, which is important for many applications.

- Versatility: Suitable for a wide range of applications, from limestone to basalt.

- Low Operating Costs: They have a long lifespan and require less maintenance compared to other crushers.

Applications of Cone Crushers

Cone crushers are widely used in various industries for different applications:

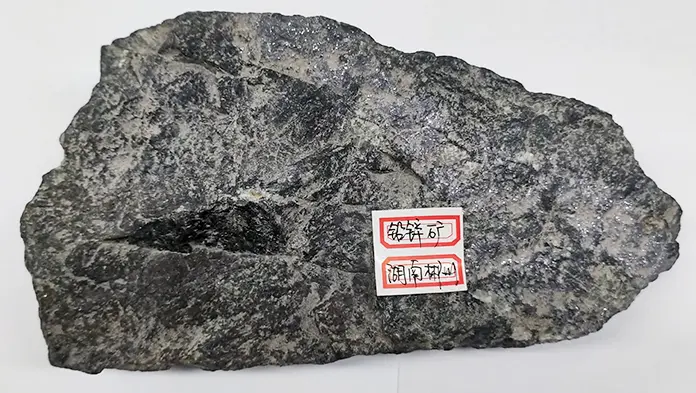

- Mining: Crushing ores and rocks for further processing.

- Construction: Producing aggregates for building and road construction.

- Recycling: Crushing concrete and other materials for reuse.

Maintenance and Safety

Proper maintenance and safety practices are crucial for the efficient operation of cone crushers:

Maintenance Tips

- Regular Inspection: Check wear parts and replace them as needed.

- Lubrication: Ensure all moving parts are properly lubricated.

- Hydraulic System: Regularly check and maintain the hydraulic system.

Safety Precautions

- Training: Ensure operators are trained in safe operating procedures.

- Lockout/Tagout: Follow proper lockout/tagout procedures during maintenance.

- Protective Gear: Use appropriate personal protective equipment (PPE).

Conclusion

Cone-type rock crushers are essential machines in the mining and construction industries, offering efficient and versatile crushing solutions. Understanding their operation, types, advantages, and maintenance requirements can help operators maximize their productivity and safety.