What is quarry crushing

Time:12 September 2025

Quarry crushing is a critical process in the mining and construction industries, involving the reduction of large rocks into smaller, manageable pieces. This process is essential for producing aggregates used in various applications, from construction to road-building. This article explores the intricacies of quarry crushing, its importance, and the technologies involved.

Understanding Quarry Crushing

Quarry crushing involves several stages and techniques designed to break down rock material into smaller sizes. The primary goal is to produce aggregates that meet specific size and quality requirements.

Key Components of Quarry Crushing

- Extraction: The initial step involves extracting raw materials from the earth. This is typically done using heavy machinery such as excavators and loaders.

- Crushing: The extracted materials are then processed through crushers to reduce their size.

- Screening: After crushing, the materials are screened to separate them into different size categories.

- Transportation: The final aggregates are transported to their intended destinations for use in various applications.

Types of Crushers Used in Quarry Crushing

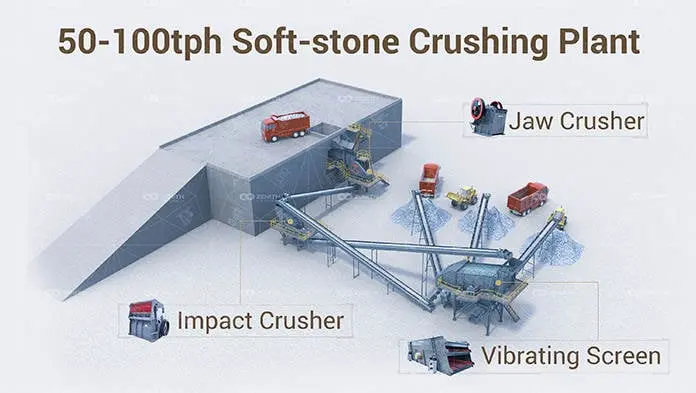

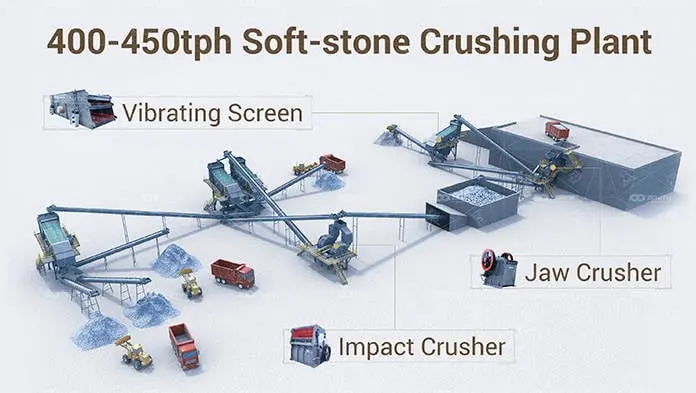

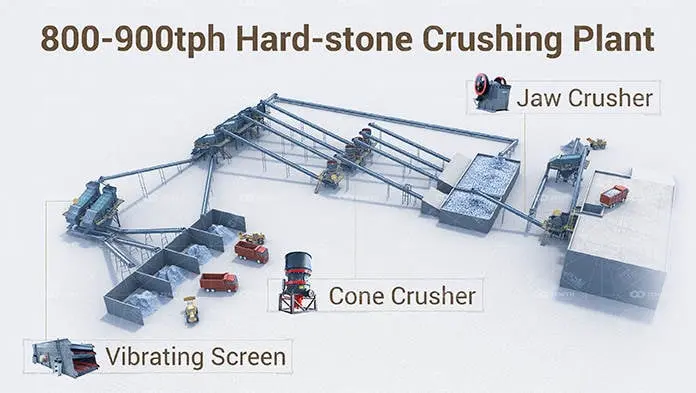

Different types of crushers are utilized in the quarry crushing process, each designed for specific applications and material types.

Primary Crushers

Primary crushers are the first stage of material reduction. They handle large, coarse materials directly from the quarry.

- Jaw Crushers: These are used for the initial crushing of hard materials. They operate by compressing the material between a stationary piece and a moving piece.

- Gyratory Crushers: Similar to jaw crushers, gyratory crushers are used for primary crushing but offer higher capacity.

Secondary Crushers

Secondary crushers further reduce the size of materials after primary crushing.

- Cone Crushers: These crushers are used for secondary crushing and are known for their ability to produce fine aggregates.

- Impact Crushers: Suitable for softer materials, impact crushers use high-speed impact to break down materials.

Tertiary Crushers

Tertiary crushers are used for final reduction and refinement of materials.

- Vertical Shaft Impact Crushers (VSI): These are used for producing high-quality, cubical aggregates.

- Hammer Mills: Often used for softer materials, hammer mills employ a series of hammers to shatter and disintegrate the material.

The Quarry Crushing Process

The quarry crushing process is a multi-stage operation that involves several steps to ensure the production of high-quality aggregates.

1. Extraction

The process begins with the extraction of raw materials. This involves:

- Drilling and Blasting: To loosen the rock material from the quarry face.

- Loading and Hauling: Using heavy machinery to transport the extracted materials to the crushing site.

2. Crushing

Once the materials are extracted, they undergo crushing:

- Primary Crushing: Large rocks are reduced to smaller sizes using jaw or gyratory crushers.

- Secondary Crushing: Further reduction using cone or impact crushers.

- Tertiary Crushing: Final refinement using VSI or hammer mills.

3. Screening

After crushing, the materials are screened to separate them into different size fractions. This step ensures that aggregates meet specific size requirements.

4. Transportation

The final aggregates are transported to construction sites or storage facilities. This involves:

- Loading onto Trucks: Using conveyors or loaders.

- Delivery: Ensuring timely and efficient transport to the destination.

Importance of Quarry Crushing

Quarry crushing is vital for several reasons:

- Resource Utilization: Efficiently converts raw materials into usable aggregates.

- Economic Impact: Supports construction and infrastructure development, driving economic growth.

- Environmental Considerations: Proper management and technology reduce environmental impact, promoting sustainability.

Technologies in Quarry Crushing

Advancements in technology have significantly improved the efficiency and effectiveness of quarry crushing.

Automation and Control Systems

Modern quarry crushing operations often incorporate automation and control systems to enhance productivity and safety.

- Automated Crushers: Enable precise control over crushing operations, improving consistency and quality.

- Monitoring Systems: Provide real-time data on equipment performance and material quality.

Energy Efficiency

Energy-efficient technologies are increasingly adopted to reduce operational costs and environmental impact.

- Variable Frequency Drives (VFDs): Optimize motor speed and reduce energy consumption.

- Hybrid Crushers: Combine different crushing technologies to enhance efficiency.

Conclusion

Quarry crushing is a complex, multi-stage process essential for producing high-quality aggregates. Understanding the components, types of crushers, and technologies involved is crucial for optimizing operations and ensuring sustainability in the mining and construction industries. With continuous advancements in technology, quarry crushing will continue to evolve, meeting the demands of modern infrastructure development.