What is the beneficiation technique for marble

Time:23 September 2025

Marble is a metamorphic rock composed primarily of calcite, which is a crystalline form of calcium carbonate. It is widely used in construction, sculpture, and various industrial applications due to its aesthetic appeal and durability. However, raw marble often contains impurities that can affect its quality and usability. Beneficiation techniques are employed to enhance the quality of marble by removing these impurities and improving its physical properties.

Overview of Marble Beneficiation

Beneficiation is the process of improving the economic value of a mineral by removing impurities and enhancing its properties. For marble, this involves several techniques designed to achieve the following:

- Purification: Removing unwanted materials and impurities.

- Enhancement: Improving the physical and chemical properties.

- Optimization: Ensuring the marble meets specific industrial standards.

Techniques Used in Marble Beneficiation

1. Crushing and Grinding

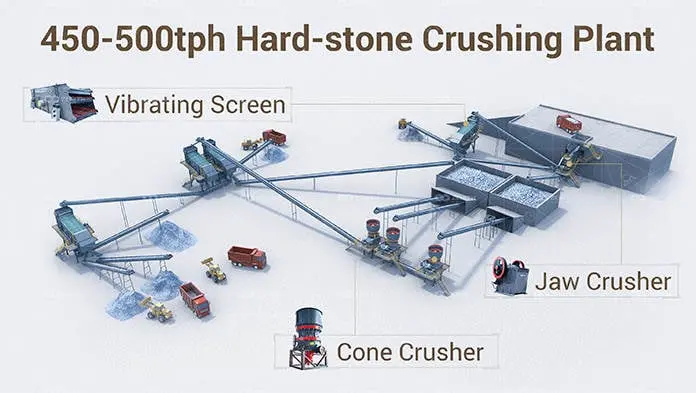

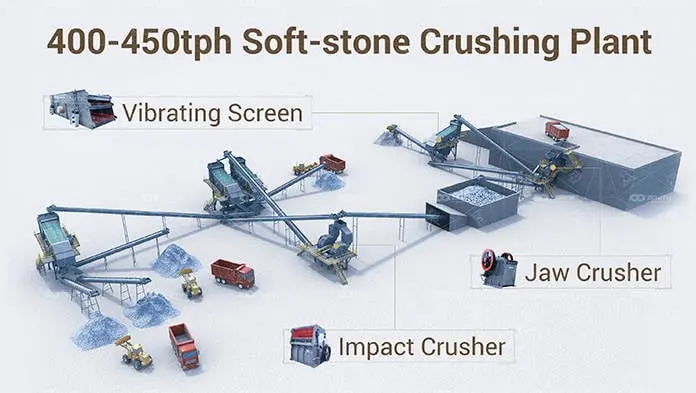

The initial step in marble beneficiation is crushing and grinding. This process reduces the size of the marble pieces and prepares them for further processing.

- Crushing: Large marble blocks are broken down into smaller pieces using jaw crushers or cone crushers.

- Grinding: The crushed marble is ground into finer particles using ball mills or vertical roller mills.

2. Screening

Screening is used to separate marble particles based on size. This ensures uniformity and prepares the marble for subsequent processes.

- Vibrating Screens: These are used to classify marble particles into different size ranges.

- Mesh Screens: Specific mesh sizes are used to achieve desired particle size distribution.

3. Flotation

Flotation is a separation technique that utilizes differences in surface properties to remove impurities from marble.

- Reagents: Chemicals are added to create hydrophobic surfaces on impurities, allowing them to be separated from the marble.

- Air Bubbles: Air is introduced to create bubbles that attach to impurities and float them to the surface for removal.

4. Magnetic Separation

Magnetic separation is employed to remove ferrous impurities from marble.

- Magnetic Drums: These are used to attract and remove iron particles from the marble.

- High-Intensity Magnetic Separators: Effective for removing even weakly magnetic impurities.

5. Chemical Treatment

Chemical treatment involves using acids or other chemicals to dissolve impurities and enhance marble quality.

- Acid Washing: Hydrochloric acid or other acids are used to remove surface stains and impurities.

- Chemical Polishing: Chemicals are applied to improve the surface finish and brightness of marble.

Benefits of Marble Beneficiation

Beneficiating marble offers several advantages:

- Improved Quality: Enhances the aesthetic and physical properties of marble.

- Increased Market Value: Higher quality marble fetches better prices in the market.

- Expanded Applications: Purified marble can be used in diverse applications, including high-end architectural projects.

- Environmental Impact: Reduces waste and promotes sustainable use of marble resources.

Challenges in Marble Beneficiation

Despite its benefits, marble beneficiation faces certain challenges:

- Cost: The processes involved can be expensive, affecting the overall cost-effectiveness.

- Complexity: Requires sophisticated equipment and expertise.

- Environmental Concerns: Chemical treatments may pose environmental risks if not managed properly.

Conclusion

Marble beneficiation is a crucial process that enhances the quality and usability of marble by removing impurities and improving its properties. Through techniques such as crushing, grinding, flotation, magnetic separation, and chemical treatment, marble can be purified and optimized for various applications. While the process offers significant benefits, it also presents challenges that must be addressed to ensure sustainable and cost-effective marble production.