What role does gypsum play in the manufacture of cement

Time:23 September 2025

Gypsum is a crucial component in the production of cement, serving several essential functions that contribute to the quality and performance of the final product. This article explores the role of gypsum in cement manufacture, detailing its functions, benefits, and the processes involved.

Introduction to Gypsum

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate (CaSO₄·2H₂O). It is widely used in various industries, including construction, agriculture, and manufacturing. In cement production, gypsum plays a vital role in controlling the setting time and improving the overall properties of cement.

Functions of Gypsum in Cement

Gypsum serves multiple functions in the cement manufacturing process:

– Gypsum is primarily added to cement to control the setting time. Without gypsum, cement would set too quickly, making it difficult to work with and potentially compromising structural integrity.

– By slowing down the hydration process of cement, gypsum allows for adequate time for mixing, transporting, and placing the concrete.

- Improvement of Workability

– Gypsum enhances the workability of cement, making it easier to mix and apply.

– It helps in achieving a smoother texture and consistency, which is crucial for construction applications.

– Gypsum contributes to reducing shrinkage in cement, minimizing the risk of cracks and structural failures.

– It helps maintain the dimensional stability of concrete structures.

Benefits of Using Gypsum in Cement

The inclusion of gypsum in cement offers several benefits:

– Gypsum improves the durability of cement by preventing rapid setting and reducing the risk of early-age cracking.

– Gypsum is a cost-effective additive that enhances the performance of cement without significantly increasing production costs.

– Gypsum is a natural mineral that is abundantly available, making it an environmentally friendly choice for cement production.

Cement Manufacturing Process Involving Gypsum

The process of incorporating gypsum into cement involves several steps:

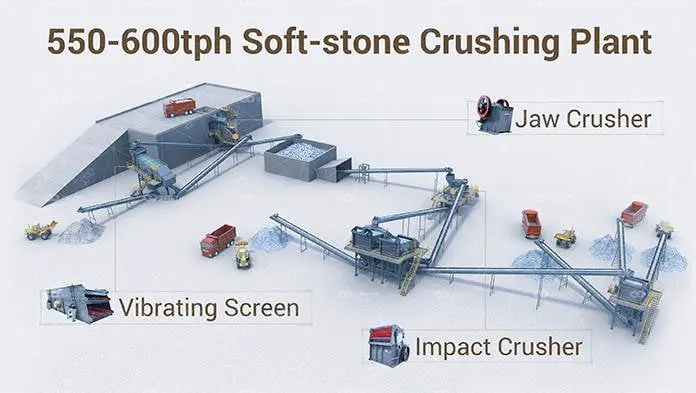

- Extraction and Preparation

– Gypsum is extracted from mines and then crushed into a fine powder.

– The prepared gypsum powder is stored and ready for use in cement manufacturing.

– During the cement manufacturing process, gypsum is mixed with clinker (the main component of cement) in specific proportions.

– The typical ratio is about 3-5% gypsum to clinker, although this can vary depending on the desired properties of the cement.

– The mixture of clinker and gypsum is ground together to produce cement powder.

– This grinding process ensures that gypsum is evenly distributed throughout the cement, facilitating uniform setting and hardening.

– Throughout the manufacturing process, quality control measures are implemented to ensure the correct proportions and consistency of the cement.

Conclusion

Gypsum plays a pivotal role in the manufacture of cement, influencing its setting time, workability, and durability. By understanding the functions and benefits of gypsum, manufacturers can produce high-quality cement that meets the demands of various construction applications. The integration of gypsum into the cement production process highlights its importance as a reliable and effective additive, contributing to the overall success of cement as a building material.