What is gradation in a crusher

Time:12 September 2025

Gradation in a crusher refers to the distribution of particle sizes in a given aggregate sample. It is a critical factor in determining the quality and performance of the aggregate material, which is used in various construction applications, such as concrete, asphalt, and road base materials. Understanding gradation helps in optimizing crusher operations and ensuring the desired material properties.

Importance of Gradation

Gradation plays a vital role in:

- Strength and Stability: Proper gradation ensures that aggregates interlock effectively, providing strength and stability to the final product.

- Workability: It affects the ease with which concrete or asphalt can be mixed, placed, and compacted.

- Durability: Well-graded aggregates lead to more durable construction materials, reducing maintenance and repair costs.

- Economy: Optimizing gradation can reduce the need for additional materials, thus lowering costs.

Gradation Parameters

Gradation is characterized by several parameters:

- Particle Size Distribution (PSD): The range of particle sizes present in the aggregate.

- Fineness Modulus (FM): An index number that represents the mean size of the particles in a sample.

- Uniformity Coefficient (Cu): A measure of the range of particle sizes and their distribution.

- Coefficient of Gradation (Cc): Indicates the smoothness of the gradation curve.

Gradation Curves

Gradation is often represented graphically using a gradation curve, also known as a particle size distribution curve. This curve is plotted with:

- X-axis: Particle size (usually on a logarithmic scale)

- Y-axis: Cumulative percentage passing or retained

Types of Gradation

- Well-Graded: A smooth gradation curve with a wide range of particle sizes.

- Poorly-Graded: A steep curve indicating a narrow range of particle sizes.

- Gap-Graded: A curve with one or more missing size ranges.

- Open-Graded: A curve with few fines, resulting in a more porous material.

Measuring Gradation

Gradation is typically measured using sieve analysis, which involves:

- Sample Preparation: Collecting a representative sample of the aggregate.

- Sieve Stacking: Arranging a series of sieves with decreasing mesh sizes.

- Shaking: Passing the sample through the sieves to separate particles by size.

- Weighing: Measuring the mass of material retained on each sieve.

- Calculating: Determining the percentage of material passing each sieve to construct the gradation curve.

Impact of Crusher Type on Gradation

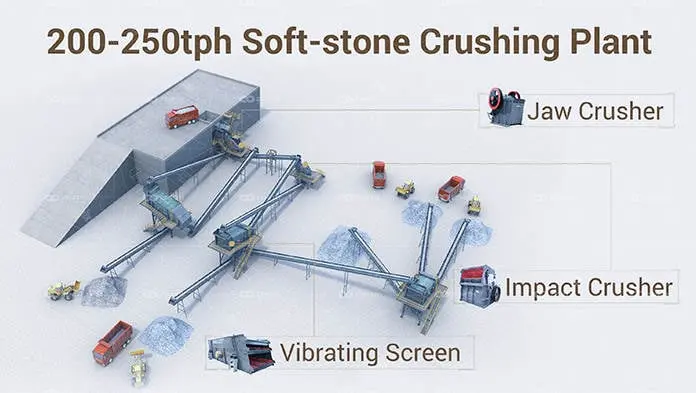

Different types of crushers produce varying gradations:

- Jaw Crushers: Typically produce a more uniform particle size distribution.

- Cone Crushers: Known for producing a more cubical product with fewer fines.

- Impact Crushers: Often create a higher percentage of fines and a more rounded particle shape.

Optimizing Crusher Gradation

To optimize crusher gradation:

- Adjust Crusher Settings: Modify the crusher’s closed-side setting (CSS) to control the size of the output material.

- Select Appropriate Crusher Type: Choose the crusher type that best suits the desired gradation and material properties.

- Regular Maintenance: Ensure crushers are well-maintained to avoid irregular wear patterns that can affect gradation.

Conclusion

Understanding and controlling gradation in a crusher is crucial for producing high-quality aggregate materials. By focusing on gradation, operators can enhance the performance, durability, and economy of construction projects. Proper measurement and optimization of gradation lead to better material properties and more efficient use of resources.