What is mine tailings and how to process

Time:19 September 2025

Mine tailings are a significant byproduct of the mining process, and their management is a critical aspect of mining operations. This article explores what mine tailings are, their environmental impact, and the various methods used to process and manage them.

What are Mine Tailings?

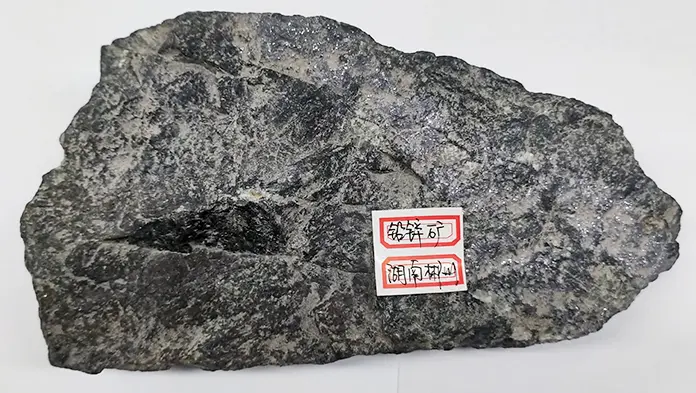

Mine tailings are the materials left over after the extraction of valuable minerals or metals from ore. These materials can consist of:

- Crushed rock

- Water

- Chemical residues from the extraction process

Characteristics of Mine Tailings

- Composition: Tailings can vary widely in composition, depending on the type of ore and the extraction process used.

- Physical Form: They are often in the form of a slurry, a mixture of solid particles and water.

- Volume: The volume of tailings produced can be substantial, often exceeding the volume of the extracted ore.

Environmental Impact of Mine Tailings

The management of mine tailings is crucial due to their potential environmental impact:

- Water Pollution: Tailings can leach harmful chemicals into water sources.

- Soil Degradation: The deposition of tailings can lead to soil contamination and erosion.

- Air Pollution: Dust from dry tailings can contribute to air quality issues.

Processing Mine Tailings

Processing mine tailings involves several steps to minimize their environmental impact and, in some cases, recover additional resources. The following are common methods used in tailings processing:

1. Thickening

Thickening involves the removal of excess water from the tailings slurry to reduce its volume. This process is achieved through:

- Gravity Thickeners: Large tanks where solid particles settle at the bottom.

- Filtration: Mechanical separation of solids from liquids.

2. Dewatering

Further dewatering of tailings can be achieved through:

- Centrifuges: Machines that use centrifugal force to separate solids from liquids.

- Filter Presses: Equipment that compresses the slurry to remove water.

3. Tailings Storage

Proper storage of tailings is crucial to prevent environmental contamination. Common storage methods include:

- Tailings Ponds: Large, engineered basins designed to contain tailings and allow water to evaporate.

- Dry Stacking: A method where dewatered tailings are stacked in a dry form, reducing the risk of water contamination.

4. Reprocessing

Reprocessing involves extracting additional minerals from tailings, which can be economically viable and reduce the volume of waste. This process includes:

- Flotation: A method to separate valuable minerals from tailings using chemicals and air bubbles.

- Leaching: The use of chemical solutions to dissolve and recover metals from tailings.

Innovative Approaches in Tailings Management

Recent advancements have introduced innovative approaches to tailings management:

- Paste Tailings: A thickened form of tailings that reduces water content and improves stability.

- Geopolymerization: The conversion of tailings into construction materials through chemical processes.

- Bioremediation: The use of microorganisms to detoxify and stabilize tailings.

Conclusion

Mine tailings are an inevitable byproduct of mining operations, but their impact can be mitigated through effective processing and management techniques. By employing methods such as thickening, dewatering, and reprocessing, the mining industry can reduce the environmental footprint of tailings and, in some cases, recover additional resources. As technology advances, innovative approaches continue to emerge, offering new solutions for sustainable tailings management.