What are the processing equipment for feldspar powder

Time:12 September 2025

Feldspar powder is a crucial component in various industrial applications, including ceramics, glassmaking, and coatings. The production of feldspar powder involves several processing stages, each requiring specific equipment to achieve the desired quality and consistency. This article provides a comprehensive overview of the processing equipment used in the production of feldspar powder.

Overview of Feldspar Processing

The processing of feldspar involves several stages, including crushing, grinding, separation, and drying. Each stage requires specialized equipment to ensure efficient and effective production.

Key Processing Stages

- Crushing: Reducing the size of raw feldspar ore.

- Grinding: Further reducing particle size to achieve powder form.

- Separation: Removing impurities and enhancing purity.

- Drying: Ensuring moisture content is suitable for application.

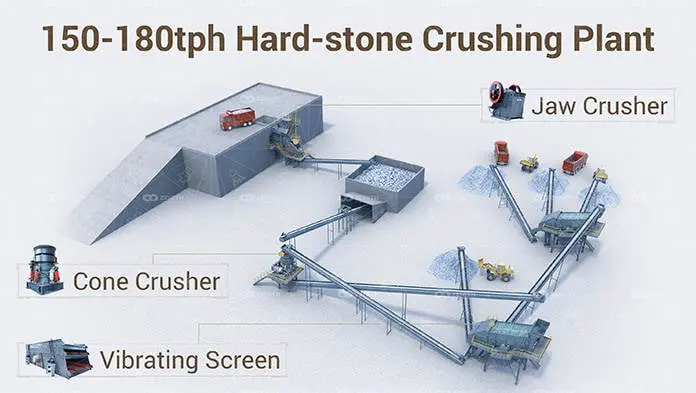

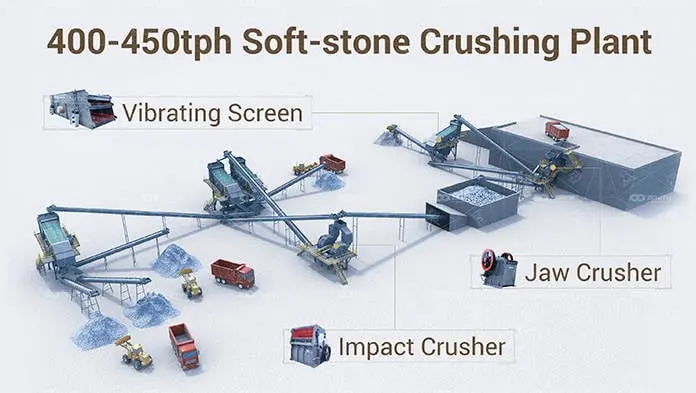

Crushing Equipment

The first step in feldspar processing is crushing, where large chunks of raw feldspar are reduced to smaller sizes. This stage is critical for facilitating subsequent grinding operations.

Types of Crushing Equipment

– Function: Used for primary crushing of feldspar.

– Features: High efficiency, capable of handling large feed sizes.

– Function: Suitable for secondary crushing.

– Features: Offers fine crushing capabilities with adjustable settings.

Grinding Equipment

Once feldspar is crushed, it undergoes grinding to achieve a fine powder. This stage is essential for applications requiring specific particle sizes.

Types of Grinding Equipment

– Function: Utilized for grinding feldspar to a fine powder.

– Features: High capacity and uniform particle size distribution.

– Function: Effective for producing fine feldspar powder.

– Features: Energy-efficient and suitable for small to medium-scale operations.

Separation Equipment

Separation is a crucial stage in feldspar processing, aimed at removing impurities and enhancing the purity of the final product.

Types of Separation Equipment

– Function: Removes iron and other magnetic impurities.

– Features: High precision and efficiency.

– Function: Used for separating feldspar from quartz and other minerals.

– Features: Effective for achieving high-purity feldspar powder.

Drying Equipment

The final stage in feldspar processing is drying, which ensures that the powder has the appropriate moisture content for its intended application.

Types of Drying Equipment

– Function: Used for drying feldspar powder.

– Features: High throughput and uniform drying.

– Function: Provides efficient drying with controlled temperature.

– Features: Suitable for heat-sensitive materials.

Conclusion

The production of feldspar powder involves several critical stages, each requiring specialized equipment to ensure quality and efficiency. From crushing and grinding to separation and drying, the choice of equipment plays a significant role in determining the final product’s quality. Understanding the functions and features of each type of equipment can help manufacturers optimize their feldspar processing operations, thereby enhancing product quality and meeting industry standards.