What critical in stone crusher project

Time:12 September 2025

A stone crusher project involves several critical aspects that need careful consideration to ensure the successful implementation and operation of the project. This article outlines the key components and considerations necessary for a stone crusher project.

1. Project Planning and Feasibility Study

Before embarking on a stone crusher project, it is crucial to conduct a comprehensive feasibility study. This involves:

- Market Analysis: Understanding the demand for crushed stone in the target market.

- Cost Analysis: Estimating the capital and operational costs involved in the project.

- Site Selection: Choosing an appropriate location that is accessible and has adequate raw material supply.

- Environmental Impact Assessment (EIA): Evaluating the potential environmental impacts and obtaining necessary clearances.

2. Design and Engineering

The design and engineering phase is critical to ensure the stone crusher operates efficiently and safely. Key considerations include:

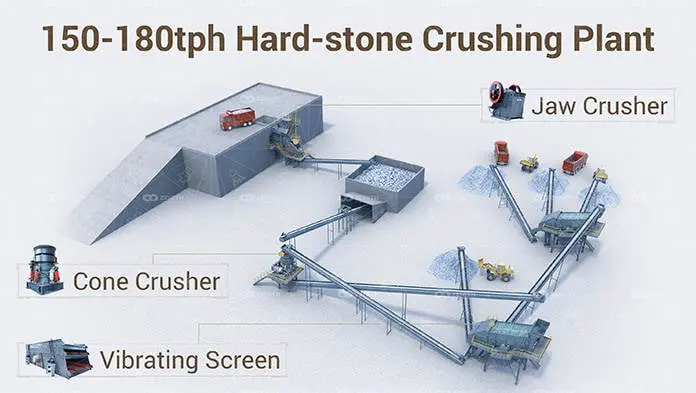

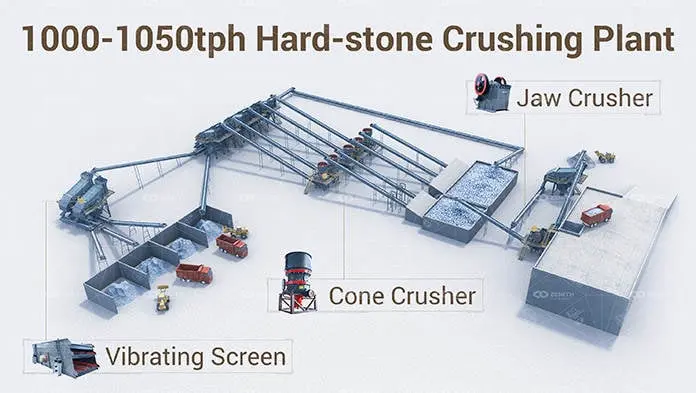

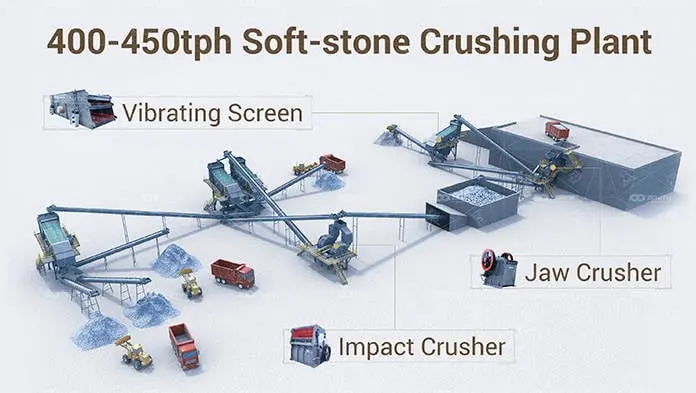

- Crusher Type Selection: Choosing the right type of crusher (e.g., jaw crusher, cone crusher, impact crusher) based on the material characteristics and project requirements.

- Layout Design: Designing the plant layout to optimize material flow and minimize bottlenecks.

- Capacity Planning: Determining the required capacity to meet production targets.

3. Equipment Procurement

Selecting and procuring the right equipment is essential for the success of the project. This involves:

- Vendor Evaluation: Assessing potential suppliers based on quality, cost, and after-sales support.

- Technical Specifications: Ensuring the equipment meets the technical requirements of the project.

- Logistics and Delivery: Planning for the timely delivery and installation of equipment.

4. Construction and Installation

The construction and installation phase involves several critical activities, including:

- Site Preparation: Clearing and leveling the site, and setting up necessary infrastructure.

- Foundation Work: Constructing robust foundations to support heavy machinery.

- Equipment Installation: Installing crushers, conveyors, screens, and other machinery according to the design specifications.

5. Operational Management

Effective operational management is crucial for the smooth functioning of the stone crusher plant. Key aspects include:

- Staff Recruitment and Training: Hiring skilled personnel and providing training on equipment operation and safety protocols.

- Maintenance Planning: Establishing a routine maintenance schedule to minimize downtime and extend equipment life.

- Quality Control: Implementing quality control measures to ensure the production of high-quality aggregate.

6. Health, Safety, and Environmental Compliance

Ensuring compliance with health, safety, and environmental regulations is a critical aspect of any stone crusher project. This includes:

- Safety Protocols: Developing and enforcing safety procedures to protect workers.

- Dust and Noise Control: Implementing measures to reduce dust and noise pollution.

- Waste Management: Proper disposal and management of waste materials to minimize environmental impact.

7. Financial Management

Effective financial management is essential to ensure the project’s profitability and sustainability. This involves:

- Budgeting and Cost Control: Monitoring expenses and ensuring the project stays within budget.

- Revenue Management: Implementing strategies to maximize revenue from the sale of crushed stone.

- Risk Management: Identifying potential financial risks and developing mitigation strategies.

Conclusion

A stone crusher project involves multiple critical aspects that require careful planning and execution. By addressing these key areas—project planning, design, procurement, construction, operations, compliance, and financial management—stakeholders can ensure the successful implementation and operation of the project, leading to sustainable profitability and minimal environmental impact.