What does a cone crusher do

Time:16 September 2025

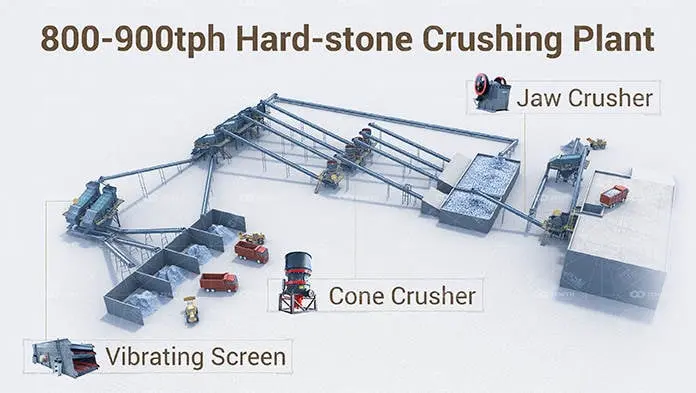

A cone crusher is a crucial piece of equipment in the mining and aggregate industries, designed to reduce the size of raw materials into smaller, more manageable pieces. This article provides an in-depth look at the functionality, components, and applications of cone crushers.

Introduction to Cone Crushers

Cone crushers are a type of compression crusher used in mining and aggregate industries. They are designed to crush materials between a stationary piece of steel and a moving piece of steel, known as the mantle and the concave. The primary purpose is to reduce the size of large rocks into smaller, more uniform pieces.

How Cone Crushers Work

Basic Working Principle

Cone crushers operate by compressing materials between the mantle and the concave. The crushing process involves:

- Feeding: Raw materials are fed into the top of the crusher.

- Compression: The mantle moves eccentrically, compressing the material against the concave.

- Discharge: Crushed material exits through the bottom of the crusher.

Crushing Process

- Initial Crushing: Large rocks are fed into the crusher.

- Secondary Crushing: The mantle compresses the material against the concave.

- Final Crushing: The material is broken down into smaller pieces and discharged.

Key Components of a Cone Crusher

Cone crushers consist of several key components that work together to achieve the crushing process:

- Mantle: The moving part that crushes the material.

- Concave: The stationary part that the mantle compresses the material against.

- Eccentric Assembly: Provides the gyrating motion to the mantle.

- Drive Mechanism: Powers the eccentric assembly.

- Feed Hopper: Where raw materials are fed into the crusher.

Types of Cone Crushers

Cone crushers come in various types, each suited for different applications:

- Standard Cone Crusher: Suitable for secondary crushing.

- Short Head Cone Crusher: Ideal for fine crushing applications.

- Hydraulic Cone Crusher: Offers advanced features like hydraulic adjustment and overload protection.

Advantages of Using Cone Crushers

Cone crushers offer several advantages:

- High Efficiency: Capable of processing large volumes of material.

- Uniform Product Size: Produces consistent and uniform particle sizes.

- Versatility: Suitable for a wide range of applications and materials.

- Durability: Built to withstand heavy-duty operations.

Applications of Cone Crushers

Cone crushers are widely used in various industries, including:

- Mining: Crushing ores and minerals.

- Construction: Producing aggregates for building projects.

- Recycling: Breaking down concrete and asphalt for reuse.

Maintenance and Safety

Regular maintenance and safety checks are essential for optimal performance and longevity:

- Routine Inspections: Check for wear and tear on components.

- Lubrication: Ensure moving parts are adequately lubricated.

- Safety Protocols: Follow safety guidelines to prevent accidents.

Conclusion

Cone crushers play a vital role in the mining and aggregate industries by efficiently reducing the size of raw materials. Understanding their functionality, components, and applications can help operators maximize their effectiveness and ensure safe operations. Whether used in mining, construction, or recycling, cone crushers are indispensable tools for material processing.