what is the cost of making gravel crusher plant 600tph

Time:12 September 2025

Creating a gravel crusher plant with a capacity of 600 tons per hour (600TPH) involves several considerations, including equipment, labor, materials, and operational costs. This article provides a comprehensive overview of the factors influencing the cost of establishing such a plant.

Key Components of a 600TPH Gravel Crusher Plant

1. Equipment Costs

The primary equipment required for a gravel crusher plant includes:

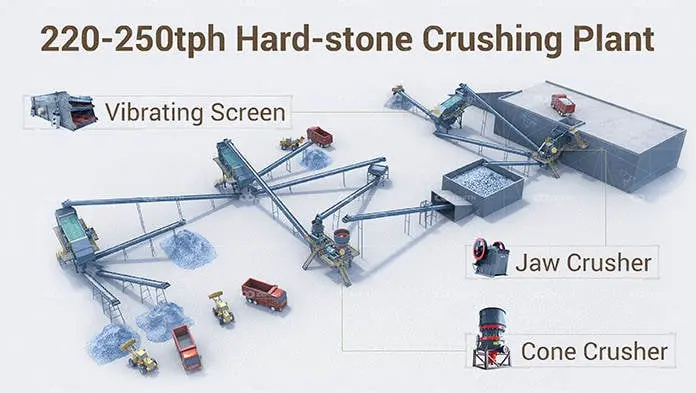

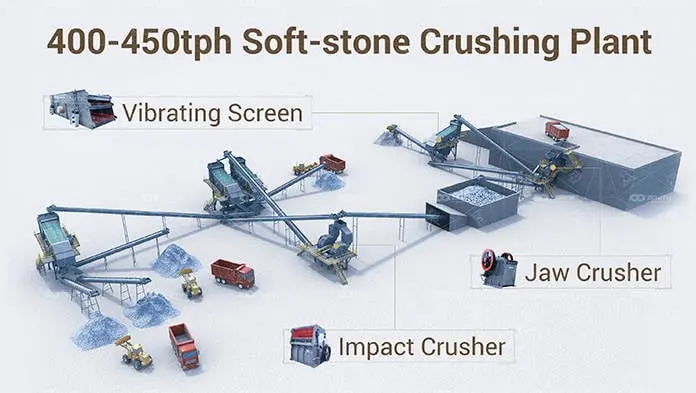

- Jaw Crusher: Essential for primary crushing of large rocks.

- Cone Crusher: Used for secondary crushing to achieve the desired size.

- Vibrating Screen: For sorting and separating different sizes of crushed gravel.

- Conveyor Belts: To transport materials between different stages of crushing and screening.

- Feeders: To ensure consistent flow of materials into crushers.

2. Material Costs

Material costs encompass:

- Raw Materials: The cost of acquiring raw gravel or stone.

- Consumables: Items such as lubricants, wear parts, and liners that need regular replacement.

3. Labor Costs

Labor costs include:

- Skilled Labor: Technicians and operators to manage and operate the machinery.

- Unskilled Labor: Workers for material handling and other manual tasks.

4. Operational Costs

Operational costs consist of:

- Energy Consumption: Electricity or fuel required to run the plant.

- Maintenance: Regular servicing and repairs to ensure smooth operation.

- Environmental Compliance: Costs associated with meeting environmental regulations and standards.

Detailed Cost Breakdown

Equipment Costs

- Jaw Crusher: $100,000 – $300,000

- Cone Crusher: $150,000 – $400,000

- Vibrating Screen: $50,000 – $150,000

- Conveyor Belts: $20,000 – $50,000 per unit

- Feeders: $10,000 – $30,000

Material Costs

- Raw Materials: $5 – $15 per ton

- Consumables: $10,000 – $30,000 annually

Labor Costs

- Skilled Labor: $50,000 – $100,000 per year per technician

- Unskilled Labor: $20,000 – $50,000 per year per worker

Operational Costs

- Energy Consumption: $50,000 – $150,000 annually

- Maintenance: $30,000 – $50,000 annually

- Environmental Compliance: $20,000 – $40,000 annually

Additional Considerations

1. Location and Site Preparation

- Land Acquisition: Costs vary significantly based on location.

- Site Preparation: Includes grading, drainage, and infrastructure setup.

2. Permits and Licenses

Obtaining necessary permits and licenses can incur additional costs and time delays.

3. Transportation and Logistics

Consider the cost of transporting equipment to the site and logistics for raw material supply.

Conclusion

The total cost of establishing a 600TPH gravel crusher plant can range from $500,000 to over $2,000,000 depending on various factors such as equipment choices, location, and operational strategies. Careful planning and budgeting are essential to ensure the project’s success and profitability.

By understanding the breakdown of costs and considering all relevant factors, stakeholders can make informed decisions and optimize their investment in gravel crusher plant development.