What is the process of mining orthoclase feldspar

Time:19 September 2025

Orthoclase feldspar, a significant mineral in the feldspar group, is widely used in the manufacturing of glass and ceramics. The mining process of orthoclase feldspar involves several stages, from exploration to extraction and processing. This article provides a comprehensive overview of the mining process.

1. Exploration and Site Assessment

The initial phase in mining orthoclase feldspar involves exploration and site assessment. This stage is crucial for determining the viability of a mining project.

- Geological Surveys: Conduct detailed geological surveys to identify potential orthoclase deposits.

- Sampling: Collect rock samples for laboratory analysis to confirm the presence and quality of orthoclase.

- Feasibility Studies: Perform economic and environmental feasibility studies to assess the potential profitability and impact of mining activities.

2. Extraction Methods

Once a viable site is identified, the next step is the extraction of orthoclase feldspar. The extraction process can vary depending on the location and geology of the deposit.

2.1 Open-Pit Mining

Open-pit mining is the most common method used for extracting orthoclase feldspar.

- Site Preparation: Clear vegetation and topsoil to expose the ore body.

- Drilling and Blasting: Use drilling and blasting techniques to break up the rock.

- Excavation: Employ heavy machinery to remove the broken rock and transport it to the processing plant.

2.2 Underground Mining

In cases where orthoclase deposits are located deep underground, underground mining methods may be employed.

- Shaft Sinking: Create vertical shafts to reach the deposit.

- Tunneling: Develop horizontal tunnels to access and extract the ore.

- Ore Removal: Use specialized equipment to transport the ore to the surface.

3. Processing of Orthoclase Feldspar

After extraction, the orthoclase feldspar undergoes several processing steps to prepare it for industrial use.

3.1 Crushing and Grinding

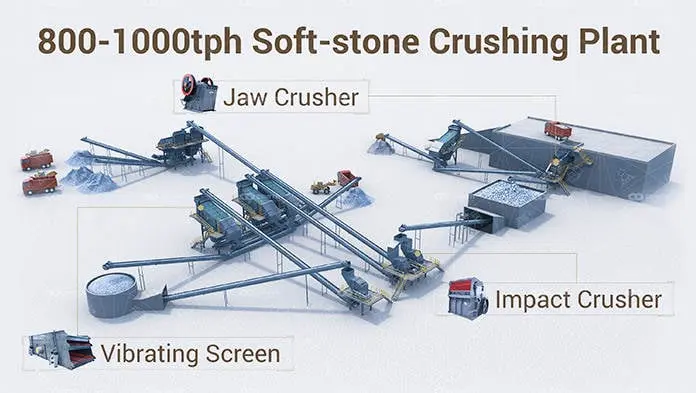

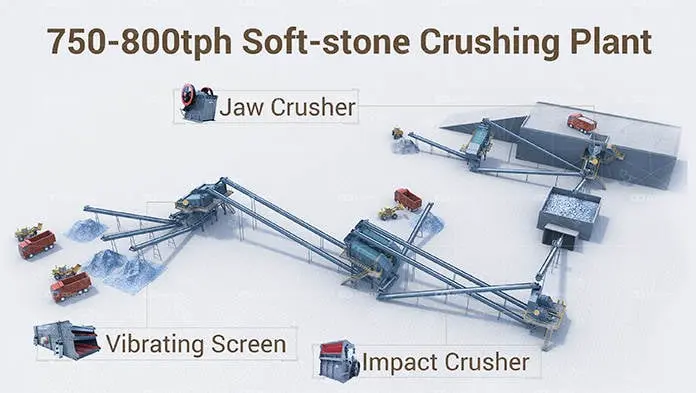

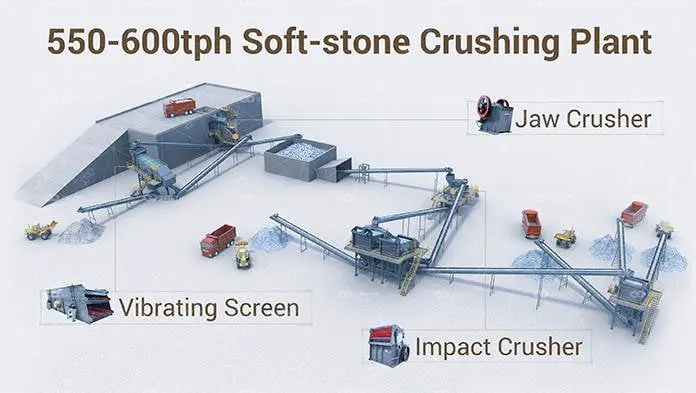

- Crushing: Use jaw crushers or cone crushers to reduce the size of the ore.

- Grinding: Employ ball mills or rod mills to further reduce the ore to a fine powder.

3.2 Separation and Purification

- Magnetic Separation: Remove iron-bearing minerals using magnetic separators.

- Flotation: Use flotation techniques to separate orthoclase from other feldspar minerals.

- Washing and Dewatering: Wash the ore to remove impurities and dewater it for further processing.

3.3 Quality Control

- Chemical Analysis: Conduct chemical analyses to ensure the purity and quality of the orthoclase.

- Particle Size Distribution: Analyze particle size to meet specific industrial requirements.

4. Environmental and Safety Considerations

Mining activities can have significant environmental and safety impacts. It is essential to implement measures to mitigate these effects.

- Environmental Management Plans: Develop plans to minimize environmental degradation, such as dust control and waste management.

- Rehabilitation: Restore mined areas to their natural state post-extraction.

- Safety Protocols: Implement safety measures to protect workers from mining hazards.

5. Conclusion

The mining of orthoclase feldspar is a complex process that involves exploration, extraction, and processing. Each stage requires careful planning and execution to ensure the efficient and sustainable production of this valuable mineral. By adhering to environmental and safety standards, the mining industry can minimize its impact and contribute positively to economic development.