What machine crushes talcum powder for building stone

Time:12 September 2025

Talcum powder, derived from talc, is a mineral composed primarily of magnesium, silicon, and oxygen. It is widely used in various industries, including cosmetics, pharmaceuticals, and building materials. In the construction industry, talcum powder is often used as a filler in building stone applications. To produce talcum powder suitable for these applications, specialized machinery is required to crush and process the mineral. This article explores the machines used for crushing talcum powder for building stone.

Overview of Talcum Powder Production

The production of talcum powder involves several stages, including extraction, crushing, milling, and packaging. The focus here is on the crushing stage, which is crucial for reducing the size of talc particles to a fine powder suitable for use in building stone.

Key Steps in Talcum Powder Production

- Extraction: Talc is extracted from open-pit mines or underground mines.

- Crushing: The extracted talc is crushed to reduce its size.

- Milling: Further processing to achieve the desired powder fineness.

- Packaging: The final product is packaged for distribution.

Machines Used for Crushing Talcum Powder

Several types of machinery are employed in the crushing process of talcum powder for building stone. Each machine has specific features and benefits that make it suitable for different stages of the process.

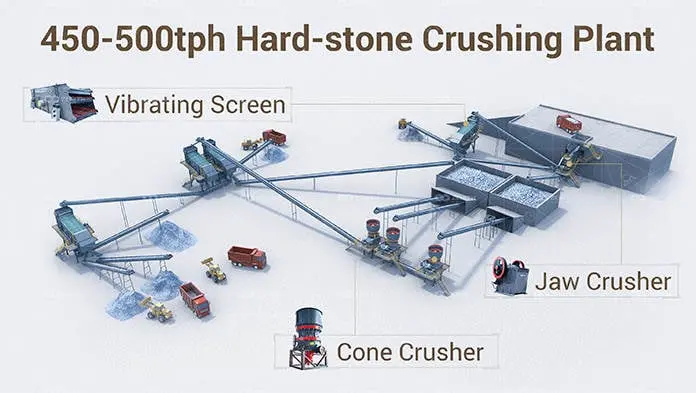

Primary Crushing Machines

Primary crushers are used to reduce large chunks of talc into smaller pieces. These machines are typically robust and capable of handling large volumes of material.

– Features: High capacity, simple structure, easy maintenance.

– Benefits: Efficient in crushing large talc rocks into smaller pieces.

– Features: Continuous operation, high throughput.

– Benefits: Suitable for large-scale operations, provides uniform size reduction.

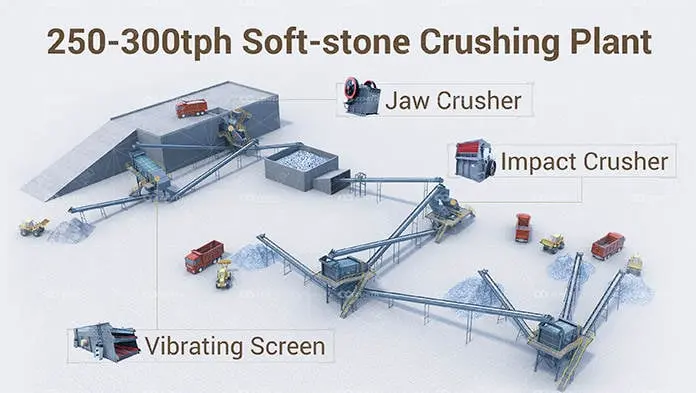

Secondary Crushing Machines

Secondary crushers further reduce the size of talc particles, preparing them for milling.

– Features: High efficiency, adjustable particle size.

– Benefits: Produces finer talc particles, ideal for secondary crushing.

– Features: High-speed rotors, adjustable impact plates.

– Benefits: Provides precise control over particle size, suitable for producing fine powder.

Tertiary Crushing Machines

For the final stage of crushing, tertiary machines are used to achieve the desired powder fineness.

– Features: High-speed operation, adjustable screen sizes.

– Benefits: Produces ultra-fine talc powder, ideal for building stone applications.

– Features: Rotating cylinder, grinding media.

– Benefits: Achieves very fine particle sizes, suitable for final processing stage.

Considerations for Choosing Crushing Machines

When selecting a machine for crushing talcum powder for building stone, several factors should be considered:

Material Properties

- Hardness: Talc is relatively soft, which affects the choice of crusher.

- Moisture Content: High moisture can impact crushing efficiency.

Production Requirements

- Capacity: The machine should meet the production volume needs.

- Fineness: Desired particle size for the final product.

Operational Factors

- Maintenance: Ease of maintenance and availability of spare parts.

- Energy Consumption: Efficiency and cost-effectiveness of the machine.

Conclusion

Crushing talcum powder for building stone involves the use of specialized machinery designed to handle the unique properties of talc. By understanding the different types of crushers and their applications, manufacturers can select the appropriate equipment to ensure efficient and effective production. Whether using jaw crushers for primary crushing or ball mills for achieving ultra-fine powder, the choice of machine plays a crucial role in the quality and consistency of the final product.