What type of crusher do I need for gold

Time:12 September 2025

When it comes to extracting gold from ore, selecting the right type of crusher is crucial to ensure efficient processing and maximize yield. This article explores the different types of crushers available and guides you in choosing the best one for gold processing.

Understanding Gold Ore

Before selecting a crusher, it is essential to understand the nature of the gold ore you are dealing with. Gold ores can vary significantly in terms of hardness, size, and mineral content. Here are some key factors to consider:

- Hardness: Gold ores can range from soft to very hard.

- Size: The size of the ore particles can affect the choice of crusher.

- Mineral Content: The presence of other minerals can impact the processing method.

Types of Crushers

There are several types of crushers available for gold processing, each with its specific applications and advantages. Below is a list of the most common types:

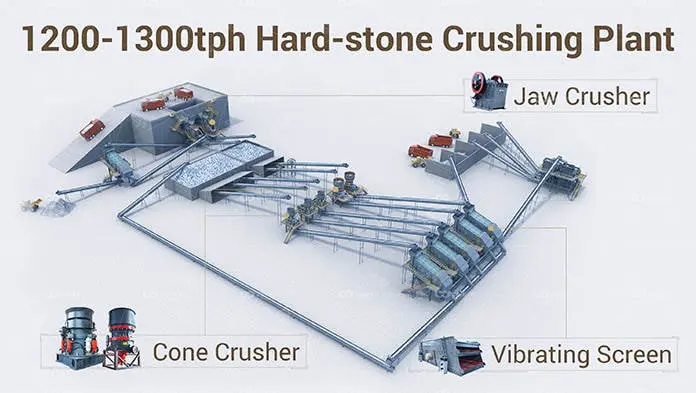

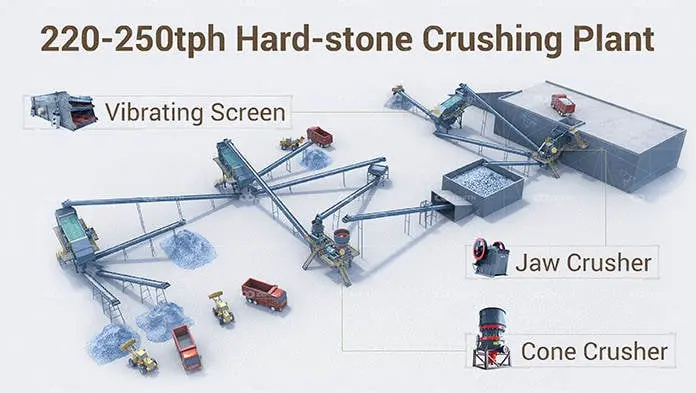

1. Jaw Crushers

Jaw crushers are typically used for primary crushing. They are ideal for handling large, hard rocks and are known for their durability and efficiency.

– Suitable for large, hard ore

– High throughput

– Simple design and easy maintenance

2. Cone Crushers

Cone crushers are used for secondary crushing. They are perfect for reducing the size of ore particles after they have been initially crushed by a jaw crusher.

– High efficiency and capacity

– Good for medium to hard ores

– Produces uniform particle size

3. Impact Crushers

Impact crushers are suitable for softer ores and are often used in tertiary crushing stages. They use impact force to break down materials.

– Good for softer ores

– Produces fine particles

– Adjustable output size

4. Hammer Mills

Hammer mills are versatile crushers that can be used for both primary and secondary crushing. They are particularly effective for softer ores and materials.

– Versatile and adaptable

– Can handle a variety of materials

– Simple design

Factors to Consider When Choosing a Crusher

When deciding on the type of crusher to use for gold processing, consider the following factors:

- Ore Characteristics: Assess the hardness, size, and mineral content of the ore.

- Production Capacity: Determine the required throughput and capacity.

- Cost: Evaluate the cost of the crusher and its operation.

- Maintenance: Consider the ease of maintenance and availability of spare parts.

- Output Size: Decide on the desired size of the crushed material.

Conclusion

Choosing the right type of crusher for gold processing is essential to ensure efficient extraction and processing. By understanding the characteristics of the gold ore and considering factors such as production capacity, cost, and maintenance, you can select the most suitable crusher for your needs. Whether you opt for a jaw crusher, cone crusher, impact crusher, or hammer mill, ensure that it aligns with your specific requirements and operational goals.