what equipment are used in the production of bentonite

Time:16 September 2025

Bentonite is a versatile clay material widely used in various industries, including drilling, foundry, and construction. The production of bentonite involves several processes, each requiring specific equipment to ensure efficiency and quality. This article provides a comprehensive overview of the equipment used in the production of bentonite.

1. Extraction and Mining Equipment

The first step in bentonite production is the extraction of raw material from the earth. This process involves several types of heavy machinery:

- Excavators: Used for digging and removing large quantities of bentonite from the ground.

- Bulldozers: Employed to clear the topsoil and access the bentonite deposits.

- Drilling Rigs: Utilized for core sampling and to determine the quality and depth of the bentonite deposit.

2. Crushing and Grinding Equipment

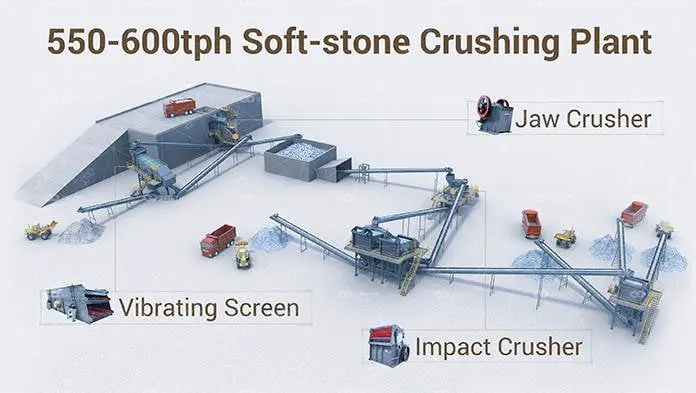

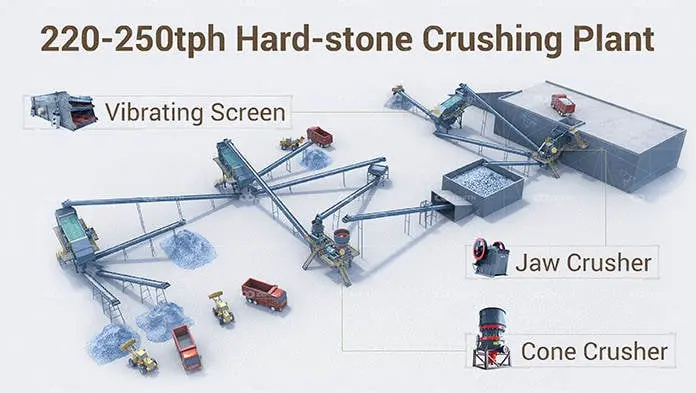

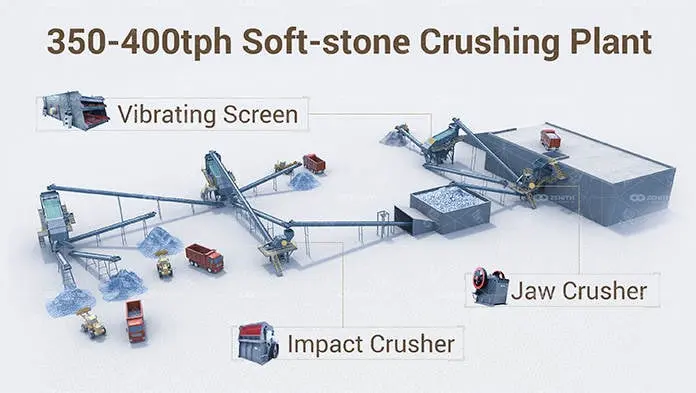

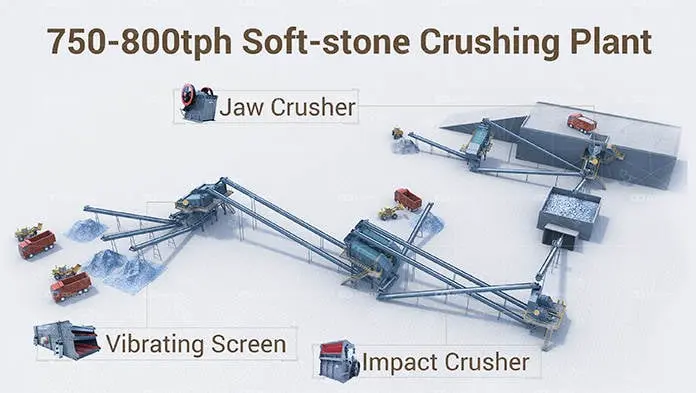

Once extracted, bentonite needs to be processed into a fine powder. This is achieved through crushing and grinding:

- Jaw Crushers: Used to break down large chunks of bentonite into smaller pieces.

- Hammer Mills: Further reduce the size of the bentonite particles.

- Ball Mills: Grind the crushed bentonite into a fine powder, which is essential for various applications.

3. Drying Equipment

Bentonite contains a significant amount of moisture when extracted. Drying is a crucial step to reduce moisture content:

- Rotary Dryers: Large cylindrical machines that use hot air to dry bentonite efficiently.

- Fluidized Bed Dryers: Provide uniform drying by suspending bentonite particles in a stream of hot air.

4. Screening and Classifying Equipment

To ensure uniform particle size, bentonite is screened and classified:

- Vibrating Screens: Separate particles based on size through a mesh screen.

- Air Classifiers: Use airflow to classify particles by size and density.

5. Mixing and Blending Equipment

For specific applications, bentonite may need to be mixed with other materials:

- Paddle Mixers: Ensure even distribution of additives within the bentonite.

- Ribbon Blenders: Provide thorough mixing of bentonite with other powders or liquids.

6. Packaging and Handling Equipment

Once processed, bentonite must be packaged for storage and transport:

- Bagging Machines: Automatically fill and seal bags with processed bentonite.

- Conveyor Systems: Transport bentonite throughout the production facility.

- Forklifts: Used for moving packaged bentonite to storage or loading areas.

7. Quality Control and Testing Equipment

Ensuring the quality of bentonite is critical for its effectiveness in various applications:

- Moisture Analyzers: Measure the moisture content of bentonite to ensure it meets specifications.

- Particle Size Analyzers: Determine the distribution of particle sizes within the bentonite.

Conclusion

The production of bentonite involves a series of complex processes, each requiring specialized equipment to ensure the final product meets industry standards. From extraction to packaging, the right machinery is essential for efficiency, quality, and safety in bentonite production. Understanding the role of each piece of equipment can help optimize the production process and improve the quality of the final product.