What equipment is required for a large quarry

Time:19 September 2025

Operating a large quarry involves a complex array of equipment, each serving a specific purpose to ensure efficient extraction and processing of materials. This article provides a comprehensive overview of the essential equipment required for a large quarry operation.

1. Drilling Equipment

Drilling is the first step in quarrying, as it involves creating holes for explosives to break up the rock.

- Drill Rigs: Used for drilling holes in the rock surface.

- Blast Hole Drills: Specifically designed for creating holes for explosive charges.

2. Blasting Equipment

Once drilling is complete, blasting equipment is used to fragment the rock.

- Explosives: Various types of explosives are used depending on the rock type and desired fragmentation.

- Detonators: Devices used to initiate the explosive charge.

- Blast Mats: Used to contain debris and reduce noise during blasting.

3. Excavation Equipment

After blasting, excavation equipment is used to remove the fragmented rock.

- Excavators: Large machines with a bucket arm used to scoop and transport materials.

- Backhoes: Smaller than excavators, used for lighter excavation tasks.

- Loaders: Used to load materials onto transport vehicles.

4. Material Handling Equipment

Efficient material handling is crucial for transporting rock from the quarry face to processing areas.

- Conveyor Belts: Automated systems for moving materials over long distances.

- Dump Trucks: Large trucks designed to transport heavy loads of rock.

- Wheel Loaders: Used for loading materials into trucks or onto conveyor belts.

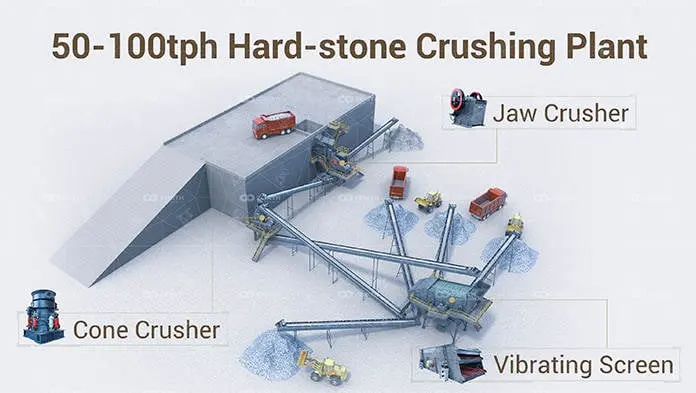

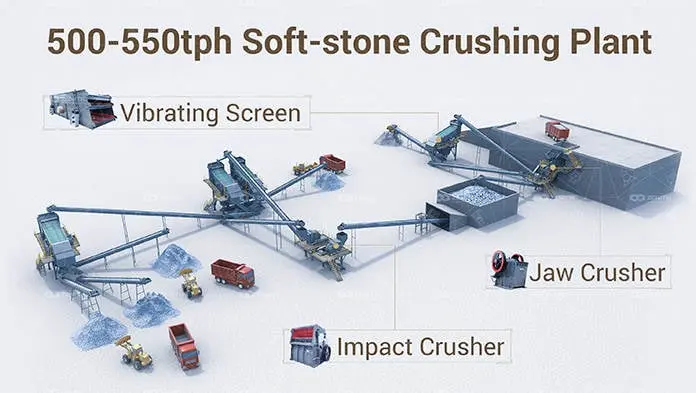

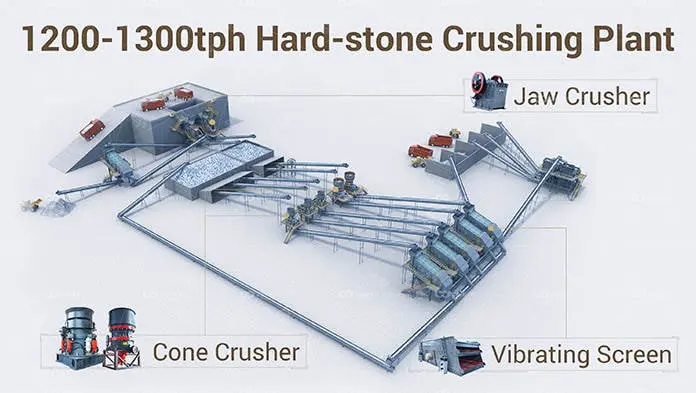

5. Crushing Equipment

Crushing equipment reduces the size of the extracted rock to make it suitable for further processing.

- Jaw Crushers: Used for primary crushing of large rocks.

- Cone Crushers: Used for secondary crushing, producing smaller rock sizes.

- Impact Crushers: Used for tertiary crushing, creating fine material.

6. Screening Equipment

Screening equipment sorts crushed rock into different sizes for various applications.

- Vibrating Screens: Used to separate materials based on size.

- Trommel Screens: Rotating drum screens used for finer separation.

7. Washing Equipment

Washing equipment cleans the material to remove impurities.

- Wash Plants: Systems that wash and classify materials.

- Sand Washers: Specifically designed to clean sand and gravel.

8. Maintenance and Support Equipment

Regular maintenance is essential to ensure the smooth operation of quarry equipment.

- Tool Kits: Comprehensive sets of tools for on-site repairs.

- Lubrication Systems: Automated systems to ensure machinery runs smoothly.

- Mobile Workshops: On-site workshops equipped for maintenance tasks.

9. Safety Equipment

Safety is paramount in quarry operations, requiring specialized equipment.

- Personal Protective Equipment (PPE): Helmets, gloves, goggles, and safety boots.

- Fire Suppression Systems: Installed on machinery to prevent fires.

- Emergency Response Kits: First aid kits and emergency supplies.

Conclusion

Running a large quarry requires a diverse range of equipment, each playing a crucial role in the extraction, processing, and transportation of materials. From drilling and blasting to crushing and screening, every piece of equipment is essential for efficient and safe quarry operations. Proper maintenance and safety measures ensure the longevity and reliability of the equipment, ultimately contributing to the success of the quarry operation.