what is a primary and secondary crusher

Time:12 September 2025

In the field of mining and construction, crushers play a pivotal role in processing raw materials. They are essential in reducing large rocks into smaller, manageable sizes. This article explores the concepts of primary and secondary crushers, their functions, and their significance in the crushing process.

What is a Crusher?

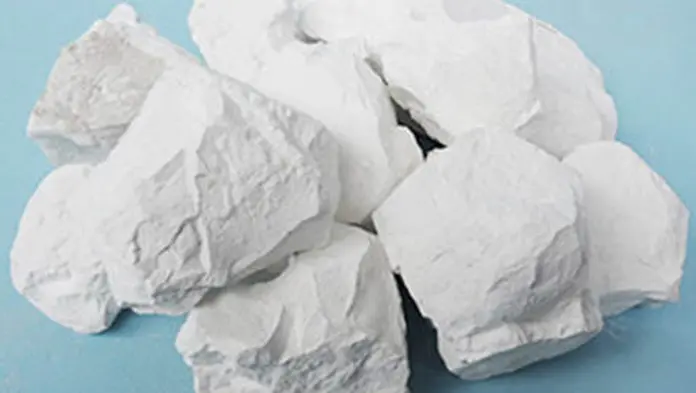

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or recycled.

Types of Crushers

Crushers are categorized based on their stage in the crushing process. The two main types are:

- Primary Crushers

- Secondary Crushers

Primary Crushers

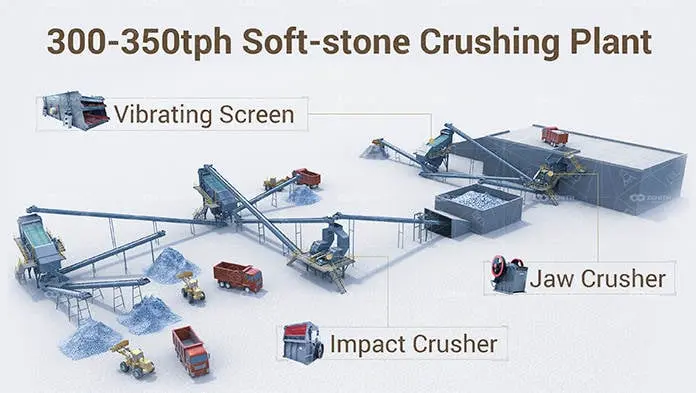

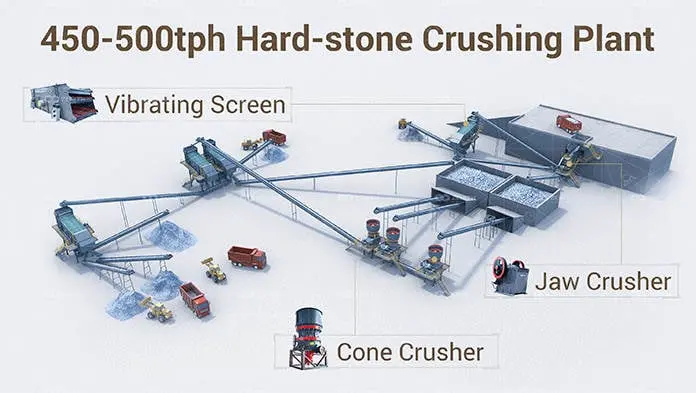

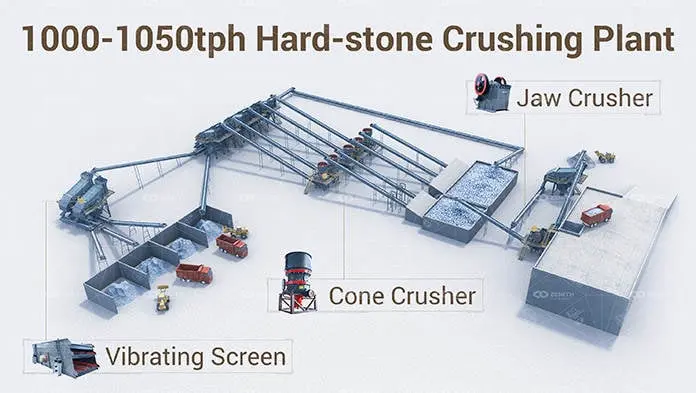

Primary crushers are the first machines in the crushing process. They are designed to handle large, rough materials directly from the mine or quarry. The primary crusher’s main purpose is to reduce the size of the raw material to a manageable level for secondary crushers.

Characteristics of Primary Crushers

- Large Feed Opening: Primary crushers have a large feed opening to accommodate the large size of the raw material.

- High Capacity: They are capable of processing large volumes of material.

- Robust Construction: Built to withstand heavy-duty operations and the harsh conditions of mining environments.

Types of Primary Crushers

- Jaw Crushers: Use compressive force for breaking material. Suitable for hard and abrasive rocks.

- Gyratory Crushers: Similar to jaw crushers but with a gyrating spindle that crushes the material against a stationary surface.

- Impact Crushers: Utilize impact force to break down materials, ideal for softer materials.

Secondary Crushers

Secondary crushers come into play after the primary crushers have reduced the material to a smaller size. The secondary crusher further reduces the material to the desired size and shape.

Characteristics of Secondary Crushers

- Smaller Feed Size: They handle material that has been pre-processed by primary crushers.

- Finer Output: Produce finer material suitable for further processing or direct use.

- Versatility: Capable of handling a variety of materials and producing different sizes and shapes.

Types of Secondary Crushers

- Cone Crushers: Use a rotating cone inside a hardened shell to crush materials. Ideal for medium to hard materials.

- Roll Crushers: Utilize two rotating cylinders to crush materials, suitable for softer materials.

- Hammer Mills: Use hammers mounted on a spinning rotor to crush materials, effective for brittle materials.

Importance of Primary and Secondary Crushers

The combination of primary and secondary crushers is crucial for efficient material processing. Here are some reasons why:

- Efficiency: By breaking down material in stages, crushers ensure efficient processing and reduce the load on subsequent machinery.

- Cost-Effectiveness: Reducing the size of materials at each stage minimizes transportation and handling costs.

- Quality Control: Ensures consistent material size for further processing or end-use.

Conclusion

Understanding the roles of primary and secondary crushers is essential in the mining and construction industries. These machines work in tandem to ensure that raw materials are efficiently processed into usable forms. By selecting the appropriate type of crusher for each stage, operations can optimize productivity and cost-effectiveness.