What is the final product of columbite

Time:19 September 2025

Columbite is a mineral that plays a crucial role in the production of various industrial products. This article explores the transformation of columbite from its raw form to its final product, detailing the processes involved and the applications of the end product.

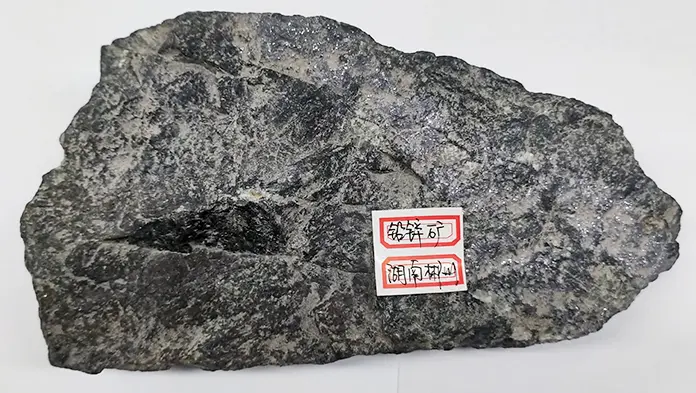

Understanding Columbite

Columbite is a black mineral group that is an ore of niobium and tantalum. It is commonly found in conjunction with tantalite, forming the mineral coltan. The primary components of columbite include:

- Niobium (Nb): A ductile metal used in steel alloys to enhance strength and resistance.

- Tantalum (Ta): Known for its high melting point and corrosion resistance, used in electronics and aerospace applications.

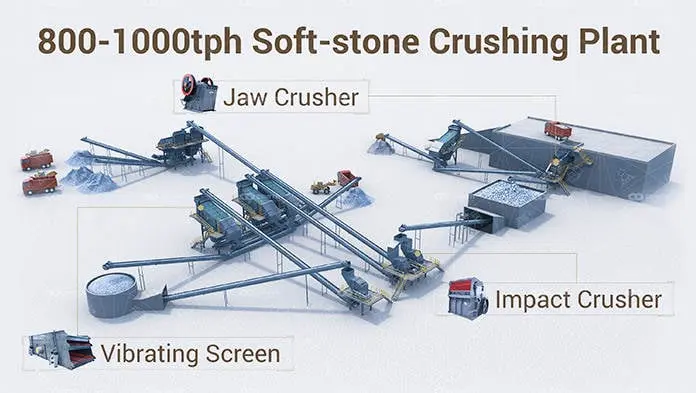

Extraction and Processing

The journey from columbite to its final product involves several key steps:

1. Mining

Columbite is extracted through mining operations, typically from:

- Open-pit mines: Where the mineral is found near the surface.

- Underground mines: For deeper deposits.

2. Concentration

Once mined, columbite undergoes concentration processes to separate niobium and tantalum from other materials. Techniques include:

- Gravity separation: Utilizing the density difference between columbite and impurities.

- Magnetic separation: Leveraging the magnetic properties of columbite.

3. Refining

The refined columbite is processed to extract niobium and tantalum. This involves:

- Chemical processing: Using hydrofluoric acid and other chemicals to isolate the metals.

- Electrolytic methods: For further purification.

Final Products

The final products derived from columbite are primarily niobium and tantalum, which have several industrial applications.

Niobium Products

Niobium is transformed into various products, including:

- Steel Alloys

– Enhances strength and weldability.

– Used in pipelines, automotive, and construction industries.

- Superalloys

– Utilized in jet engines and gas turbines.

– Provides high-temperature stability.

Tantalum Products

Tantalum is used to produce:

- Capacitors

– Essential in electronics for mobile phones, computers, and automotive electronics.

– Offers high capacitance and reliability.

- Surgical Instruments

– Due to its biocompatibility and corrosion resistance.

– Used in implants and medical devices.

Applications of Final Products

The final products of columbite have widespread applications across various industries:

- Electronics: Tantalum capacitors are critical components in modern electronic devices.

- Aerospace: Niobium superalloys are used in high-performance aircraft engines.

- Medical: Tantalum’s biocompatibility makes it ideal for surgical implants.

Conclusion

Columbite’s transformation from a raw mineral to valuable industrial products highlights its importance in modern technology and industry. The extraction and processing of niobium and tantalum from columbite enable advancements in electronics, aerospace, and medical fields, showcasing the mineral’s vital role in technological progress.