What is the role of impact crusher

Time:12 September 2025

Impact crushers are essential machines in the construction and mining industries, playing a crucial role in the processing of materials. This article explores the function, types, and applications of impact crushers.

Overview of Impact Crusher

Impact crushers are machines designed to reduce the size of large rocks, gravel, or other materials by applying force through impact. They are used in various industries, including mining, construction, and recycling.

Key Features

- High Reduction Ratio: Impact crushers can significantly reduce the size of materials, making them suitable for producing finer aggregates.

- Versatility: These machines can be used for a wide range of materials, including hard rock, soft rock, and recycled materials.

- Adjustable Output Size: The output size can be adjusted by changing the rotor speed or the gap between the impact plates.

Types of Impact Crushers

Impact crushers are categorized based on their design and the mechanism used to apply force. The main types include:

Horizontal Shaft Impact Crushers (HSI)

HSI crushers have a horizontal rotor that impacts the material. They are commonly used for:

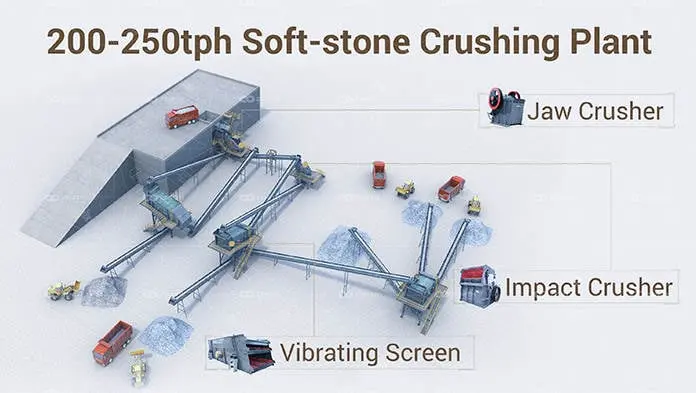

- Primary Crushing: Breaking down large materials into smaller pieces.

- Secondary Crushing: Further reducing the size of materials after primary crushing.

Vertical Shaft Impact Crushers (VSI)

VSI crushers use a vertical rotor to apply force. They are ideal for:

- Tertiary Crushing: Producing fine aggregates and sand.

- Shaping: Improving the shape and texture of materials.

Working Principle

The working principle of impact crushers involves the following steps:

- Feeding: Material is fed into the crusher through a hopper.

- Impact: The rotor spins at high speed, throwing the material against impact plates or anvils.

- Crushing: The force of impact breaks the material into smaller pieces.

- Discharge: Crushed material is discharged from the machine.

Applications of Impact Crushers

Impact crushers are versatile machines used in various applications, including:

Construction Industry

- Aggregate Production: Creating aggregates for concrete and asphalt.

- Road Building: Producing materials for road construction.

Mining Industry

- Ore Processing: Crushing ores for mineral extraction.

- Quarrying: Breaking down rocks for further processing.

Recycling Industry

- Concrete Recycling: Crushing old concrete for reuse.

- Waste Management: Processing construction waste materials.

Advantages of Impact Crushers

Impact crushers offer several advantages:

- Efficiency: High-speed rotors and impact plates ensure efficient crushing.

- Flexibility: Suitable for a wide range of materials and applications.

- Cost-Effective: Lower operational costs compared to other types of crushers.

Conclusion

Impact crushers play a vital role in the processing of materials across various industries. Their ability to efficiently reduce material size, coupled with their versatility and cost-effectiveness, makes them indispensable in modern construction, mining, and recycling operations. Understanding the different types and applications of impact crushers can help businesses choose the right machine for their specific needs.