What machinery is used to mine zinc

Time:16 September 2025

Mining zinc involves a series of processes that require specialized machinery to efficiently and safely extract the mineral from the earth. This article explores the various types of machinery used in zinc mining, detailing their functions and importance in the mining process.

Overview of Zinc Mining

Zinc mining involves extracting zinc-bearing ores from the earth and refining them into a usable form. The process typically includes exploration, extraction, processing, and refining. Each stage requires specific machinery to ensure efficiency and safety.

Types of Machinery Used in Zinc Mining

1. Exploration Machinery

Before mining can begin, exploration is necessary to locate zinc deposits. The machinery used in this stage includes:

- Drilling Rigs: Used to drill boreholes to collect samples and determine the presence of zinc.

- Seismic Equipment: Utilized to map underground formations and identify potential zinc deposits.

- Geophysical Instruments: Tools like magnetometers and gravimeters help in detecting anomalies indicative of zinc ores.

2. Extraction Machinery

Once a zinc deposit is identified, extraction machinery is employed to remove the ore from the ground. Key machines include:

- Excavators: Large machines used to dig and remove overburden and ore.

- Loaders: Equipment that loads the extracted ore onto transport vehicles.

- Blasting Tools: Used to fracture rock and access zinc deposits, often involving the use of explosives.

3. Transport Machinery

Transporting zinc ore from the mining site to processing facilities requires robust machinery:

- Conveyor Belts: Efficiently move ore over short distances within the mining site.

- Haul Trucks: Heavy-duty trucks designed to transport large quantities of ore over longer distances.

- Rail Systems: Sometimes used for moving ore in larger mining operations.

4. Processing Machinery

After extraction, zinc ore must be processed to separate the zinc from other minerals. This involves:

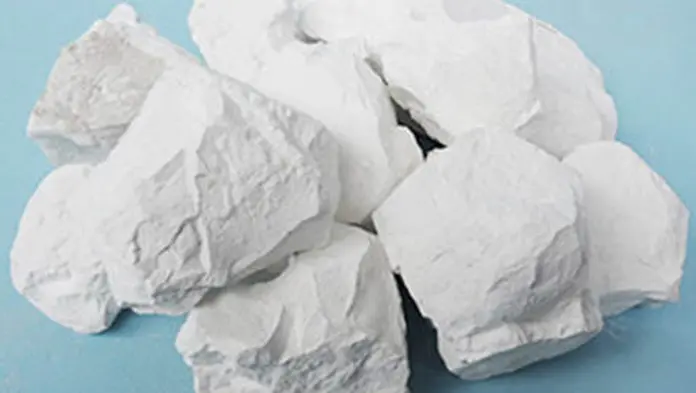

- Crushers: Machines that break down large chunks of ore into smaller, manageable pieces.

- Grinding Mills: Further reduce ore size to facilitate the separation of zinc.

- Flotation Cells: Use chemicals and air bubbles to separate zinc from other minerals in the ore.

5. Refining Machinery

The final stage in zinc mining involves refining the extracted zinc to achieve the desired purity:

- Smelters: Heat the ore to high temperatures to extract pure zinc.

- Electrolytic Cells: Use electrical currents to further purify zinc.

- Furnaces: Employed in the final stages to produce zinc ingots.

Safety and Environmental Considerations

Zinc mining machinery must adhere to strict safety and environmental standards. Key considerations include:

- Dust Control Systems: Minimize airborne particles during extraction and processing.

- Noise Reduction Equipment: Protect workers from excessive noise generated by machinery.

- Emission Control Technologies: Reduce harmful emissions from machinery, particularly during refining.

Conclusion

The machinery used in zinc mining is diverse and specialized, designed to handle the unique challenges of extracting and processing zinc ore. From exploration to refining, each stage of the mining process relies on specific equipment to ensure efficiency, safety, and environmental compliance. Understanding the role of each machine helps in optimizing the mining process and achieving successful zinc extraction.