What machines are used in quarry mining What is the role of each

Time:12 September 2025

Quarry mining is a critical industry that involves the extraction of valuable minerals and rocks from the earth’s surface. The process requires a variety of specialized machinery to ensure efficiency, safety, and precision. This article explores the different types of machines used in quarry mining and the role each one plays in the operation.

Types of Machinery Used in Quarry Mining

Quarry mining involves several stages, each requiring specific machinery. Below is a detailed look at the machines commonly used in this industry:

1. Drilling Equipment

Drilling equipment is essential for creating holes in the rock to place explosives.

- Drill Rigs: These machines are used to bore holes into the rock surface. They come in various sizes and can be either mobile or stationary.

- Jackhammers: Smaller, portable drilling tools used for breaking up rock surfaces in preparation for blasting.

2. Blasting Tools

Blasting is a critical step in quarry mining, used to break up rock formations.

- Explosive Chargers: Used to load explosives into drilled holes. They ensure precise placement for effective blasting.

- Detonators: Devices used to trigger the explosives safely and at the right time.

3. Excavation Equipment

After blasting, excavation equipment is used to remove the broken rock.

- Excavators: Large machines equipped with a bucket, arm, rotating cab, and movable tracks. They are versatile and used for digging, lifting, and moving materials.

- Loaders: These machines are used to load materials into trucks or onto conveyor belts. They come in different forms, such as wheel loaders and skid-steer loaders.

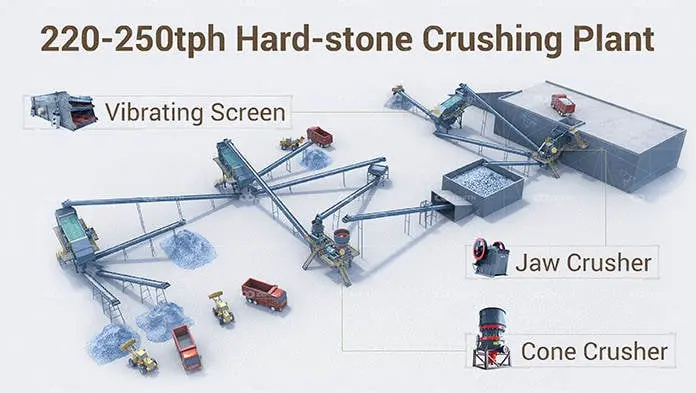

4. Crushing Machinery

Crushing machines are used to reduce the size of the extracted material.

- Jaw Crushers: Used for the primary crushing of large rocks. They work by compressing the rock between a fixed and a moving plate.

- Cone Crushers: Used for secondary crushing. They crush rocks by squeezing them between a gyrating spindle and a concave hopper.

- Impact Crushers: These machines use impact rather than pressure to crush materials. Ideal for softer rocks.

5. Screening Equipment

Screening machines separate different sizes of crushed material.

- Vibrating Screens: Use vibration to separate materials based on size. They are essential for ensuring uniformity in the final product.

- Trommel Screens: Rotating cylindrical screens that sort materials by size and are often used for larger operations.

6. Conveying Systems

Conveyors are used to transport materials within the quarry.

- Belt Conveyors: The most common type, used to move materials over long distances efficiently.

- Stackers: Used to stack bulk material into piles for storage or further processing.

7. Transportation Vehicles

These vehicles are crucial for moving materials from the quarry to processing plants or markets.

- Dump Trucks: Heavy-duty trucks designed to transport loose materials. They come in various sizes to accommodate different loads.

- Articulated Trucks: Used for off-road conditions, providing flexibility and maneuverability in rugged terrain.

The Role of Each Machine

Each machine in quarry mining plays a specific role, contributing to the overall efficiency and productivity of the operation.

Drilling and Blasting

- Purpose: To fragment the rock, making it easier to handle and process.

- Impact: Proper drilling and blasting reduce the size of the rock and minimize the need for secondary crushing.

Excavation and Loading

- Purpose: To remove and transport the fragmented rock.

- Impact: Efficient excavation and loading reduce cycle times and improve productivity.

Crushing and Screening

- Purpose: To process the rock into usable sizes and separate it by quality.

- Impact: Ensures that the final product meets industry standards and customer requirements.

Conveying and Transportation

- Purpose: To move materials efficiently within the quarry and to external locations.

- Impact: Reduces manual handling, lowers operational costs, and speeds up the production process.

Conclusion

Quarry mining relies on a variety of specialized machinery, each designed to perform specific tasks that contribute to the overall efficiency and success of the operation. From drilling and blasting to crushing and conveying, each machine plays a vital role in transforming raw rock into valuable materials. Understanding the function of each piece of equipment can help optimize operations and improve safety and productivity in quarry mining.