What process crushes basalt

Time:18 September 2025

Basalt is a dense, fine-grained igneous rock formed from the rapid cooling of basaltic lava exposed at or very near the surface of a planet or moon. Crushing basalt is a critical process in various industrial applications, including construction, road building, and aggregate production. This article explores the processes involved in crushing basalt, the equipment used, and the considerations for effective basalt crushing.

Overview of Basalt Crushing

Crushing basalt involves breaking the rock into smaller pieces suitable for use in various applications. The process typically includes several stages, each designed to reduce the size of the rock progressively.

Stages of Basalt Crushing

- Primary Crushing

– The first stage in the basalt crushing process.

– Involves reducing large basalt rocks into smaller, manageable sizes.

– Typically uses jaw crushers or gyratory crushers.

- Secondary Crushing

– Further reduces the size of basalt after primary crushing.

– Utilizes cone crushers or impact crushers to achieve finer granularity.

- Tertiary Crushing

– The final stage in the crushing process.

– Achieves the desired size and shape for specific applications.

– Often employs vertical shaft impact crushers (VSI) or high-pressure grinding rolls (HPGR).

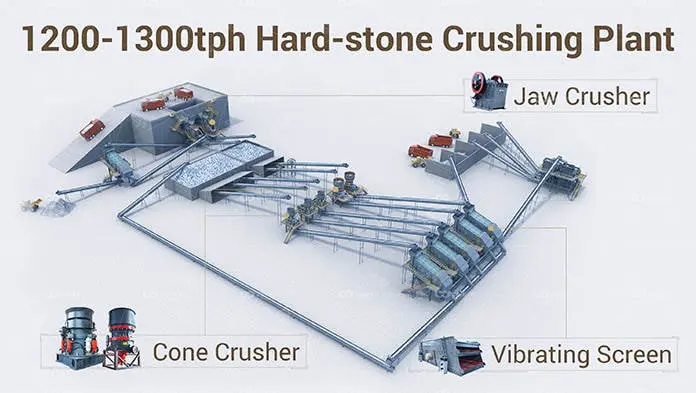

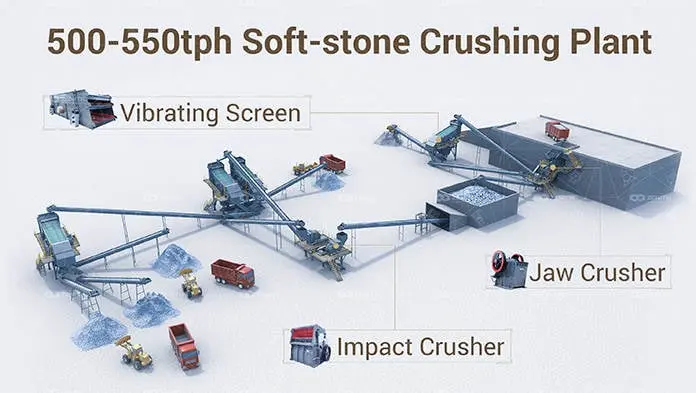

Equipment Used in Basalt Crushing

Several types of machinery are employed in the basalt crushing process, each designed to handle different stages and requirements.

Primary Crushers

– Suitable for large basalt rocks.

– Operate by compressing the rock between a fixed and a moving plate.

– Ideal for high-capacity primary crushing.

– Utilize a gyrating spindle to crush rocks against a concave surface.

Secondary Crushers

– Effective for medium to hard basalt.

– Crush rocks by squeezing them between a gyrating spindle and a concave hopper.

– Suitable for softer basalt.

– Use high-speed impact to break rocks.

Tertiary Crushers

- Vertical Shaft Impact Crushers (VSI)

– Provide excellent shape and size control.

– Use high-speed rotors to throw rocks against an anvil or rock bed.

- High-Pressure Grinding Rolls (HPGR)

– Apply high pressure to crush rocks between two rotating rolls.

– Efficient for producing fine basalt particles.

Considerations for Effective Basalt Crushing

Crushing basalt requires careful consideration of several factors to ensure efficiency and quality.

Material Properties

– Basalt is relatively hard, requiring robust equipment and techniques.

– High density demands powerful machinery to achieve desired results.

Equipment Selection

– Choose equipment based on the volume of basalt to be processed.

- End Product Specifications

– Consider the desired size and shape of the crushed basalt for specific applications.

Operational Factors

– Regular maintenance of crushing equipment ensures longevity and efficiency.

– Opt for energy-efficient machinery to reduce operational costs.

Conclusion

Crushing basalt is a complex process involving multiple stages and specialized equipment. Understanding the properties of basalt and selecting the appropriate machinery are crucial for effective crushing. By considering material characteristics, equipment capabilities, and operational factors, industries can optimize their basalt crushing processes to meet specific application needs.