what type of equipment do you need for manganese open pit mine

Time:19 September 2025

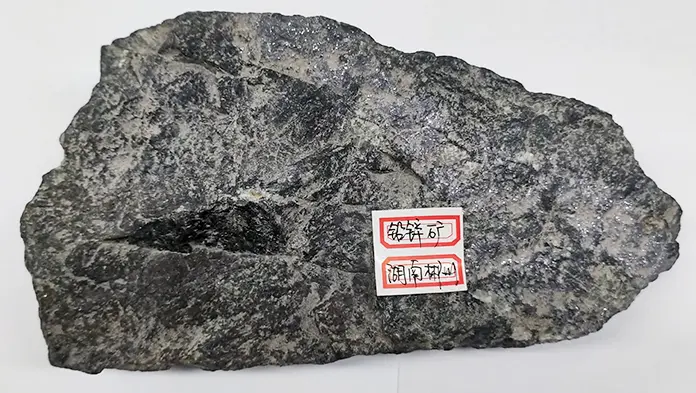

Manganese open pit mining is a complex operation that requires specialized equipment to efficiently extract and process manganese ore. This article provides a comprehensive overview of the types of equipment necessary for such mining operations.

Overview of Open Pit Mining

Open pit mining is a surface mining technique used to extract minerals from the earth. It involves the removal of large quantities of overburden to access the ore deposits. Manganese, a crucial component in steel production and various industrial applications, is often mined using this method.

Essential Equipment for Manganese Open Pit Mining

To ensure efficient and safe operations, several types of equipment are necessary in manganese open pit mining. Below is a detailed list of the essential equipment:

1. Drilling Equipment

Drilling is the first step in the mining process, used to create holes for explosives.

- Rotary Drills: Used for drilling large holes in hard rock formations.

- Percussion Drills: Suitable for softer rock formations.

- Blast Hole Drills: Specifically designed for creating holes for explosives.

2. Blasting Equipment

Blasting is used to break up the rock formations to facilitate easier extraction.

- Explosives: Various types of explosives are used depending on the rock hardness and desired fragmentation.

- Detonators and Blasting Accessories: Essential for safely initiating blasts.

3. Excavation Equipment

Excavation equipment is crucial for removing overburden and extracting ore.

- Hydraulic Excavators: Used for digging and removing overburden.

- Draglines: Suitable for large-scale excavation tasks.

- Loaders: Used for loading ore onto transport vehicles.

4. Hauling Equipment

Once the ore is extracted, it needs to be transported for processing.

- Dump Trucks: Used for transporting large quantities of ore and overburden.

- Conveyor Systems: Efficient for continuous transport of ore over long distances.

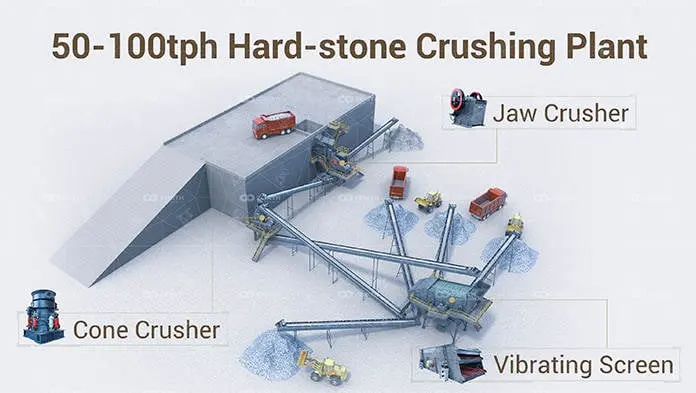

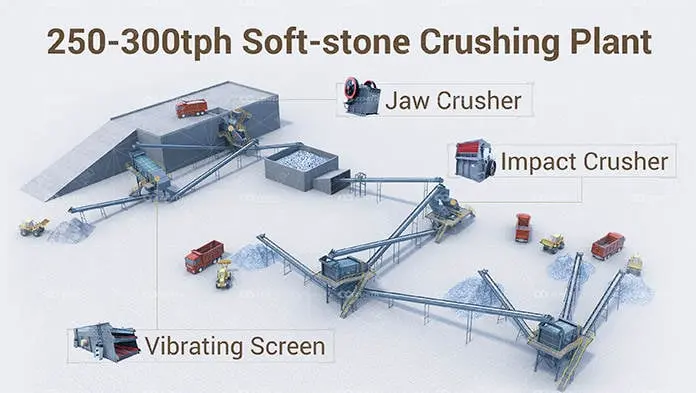

5. Crushing and Screening Equipment

Crushing and screening are vital for processing the extracted ore.

- Jaw Crushers: Used for primary crushing of large ore pieces.

- Cone Crushers: Suitable for secondary crushing.

- Vibrating Screens: Used to separate ore based on size.

6. Auxiliary Equipment

Additional equipment is necessary to support mining operations.

- Water Pumps: Essential for dewatering and dust suppression.

- Generators: Provide power for remote mining operations.

- Maintenance Equipment: Includes tools and machinery for equipment upkeep.

Safety and Environmental Considerations

While selecting equipment, it is crucial to consider safety and environmental impacts:

- Dust Suppression Systems: Minimize airborne particles during operations.

- Noise Reduction Equipment: Protect workers from excessive noise exposure.

- Eco-friendly Explosives: Reduce environmental impact during blasting.

Conclusion

Manganese open pit mining requires a diverse range of equipment to ensure efficient, safe, and environmentally responsible operations. From drilling and blasting to excavation and hauling, each piece of equipment plays a critical role in the mining process. By carefully selecting and maintaining this equipment, mining operations can achieve optimal productivity and sustainability.