What will be the cost of a stone crusher

Time:16 September 2025

Understanding the cost of a stone crusher is crucial for anyone involved in the construction or mining industry. The price of a stone crusher can vary significantly based on several factors. This article will explore these factors, providing a comprehensive guide to help you estimate the cost of a stone crusher.

Factors Influencing the Cost of a Stone Crusher

Several factors can influence the cost of a stone crusher. Understanding these can help you make an informed decision when purchasing or renting one.

1. Type of Stone Crusher

Different types of stone crushers come with varying price tags. Common types include:

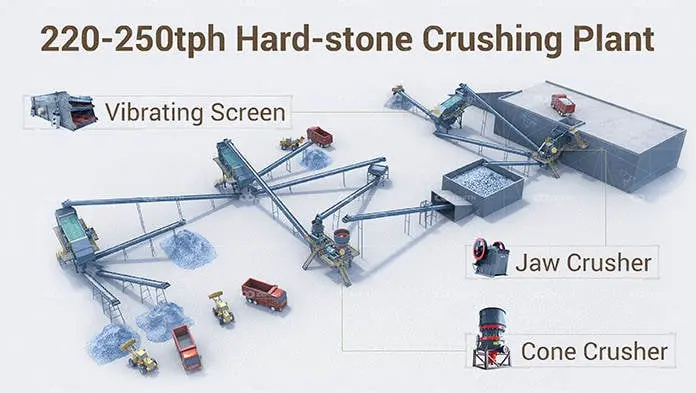

- Jaw Crushers: Known for their efficiency in crushing hard materials.

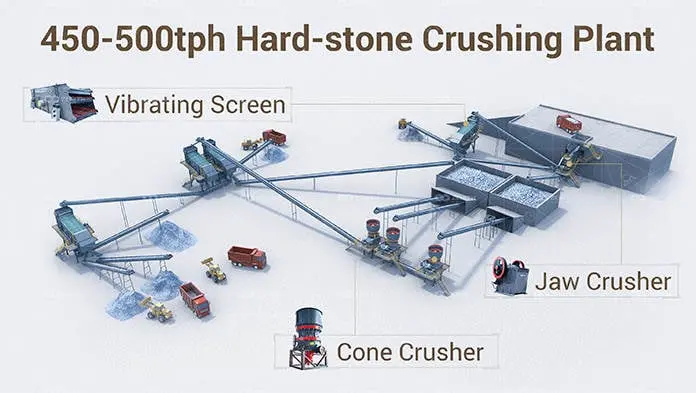

- Cone Crushers: Ideal for secondary and tertiary crushing.

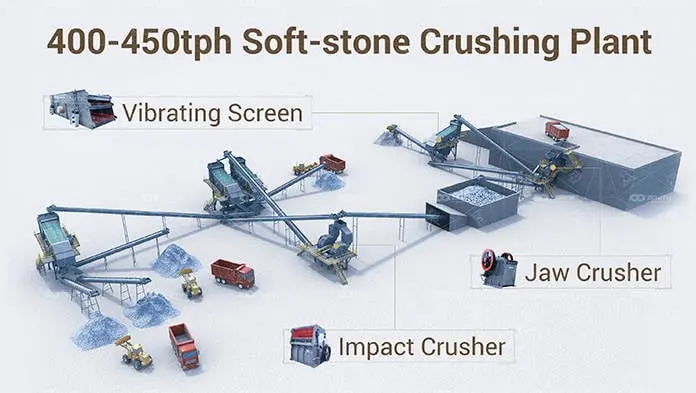

- Impact Crushers: Suitable for softer materials and recycling applications.

- Hammer Crushers: Used for medium-hard to soft materials.

Each type has its own cost implications based on its design and intended use.

2. Capacity

The capacity of a stone crusher, measured in tons per hour, directly affects its cost. Higher capacity crushers tend to be more expensive due to their increased power and efficiency.

3. Brand and Manufacturer

- Reputable Brands: Generally, well-known brands offer reliable products but at a higher price.

- Local Manufacturers: May provide cost-effective solutions but with varying quality standards.

4. Features and Technology

Advanced features and technology can increase the cost of a stone crusher. Features to consider include:

- Automation: Automated systems can enhance efficiency but add to the cost.

- Mobility: Mobile crushers offer flexibility but are typically more expensive.

- Safety Features: Enhanced safety features can also increase the price.

5. Material and Build Quality

The materials used in the construction of the crusher and its build quality can significantly impact the cost. Durable materials and robust construction often lead to higher prices but ensure longevity and reduced maintenance costs.

Estimating the Cost

To estimate the cost of a stone crusher, consider the following steps:

- Identify Your Requirements: Determine the type, capacity, and features you need.

- Research and Compare: Look at different brands and models, comparing their features and prices.

- Consider Additional Costs: Factor in installation, transportation, and maintenance costs.

- Request Quotes: Contact manufacturers or suppliers for detailed quotes based on your specifications.

Additional Costs to Consider

When budgeting for a stone crusher, it’s important to consider additional costs that may arise:

- Installation and Setup: Professional installation ensures optimal performance but comes at an additional cost.

- Transportation: Depending on the location, transportation costs can vary significantly.

- Maintenance and Repairs: Regular maintenance is essential for longevity and efficiency, adding to the overall cost.

- Operational Costs: Include fuel, electricity, and labor costs in your budget.

Conclusion

The cost of a stone crusher is influenced by various factors, including type, capacity, brand, features, and build quality. By understanding these factors and carefully estimating additional costs, you can make an informed decision that aligns with your budget and operational needs. Always consider long-term benefits such as durability and efficiency when evaluating the initial investment.