What is an eccentric shaft in a jaw crusher

Time:19 September 2025

An eccentric shaft is a critical component in jaw crushers, which are widely used in mining, construction, and demolition recycling. This article delves into the role, design, and functioning of the eccentric shaft in jaw crushers.

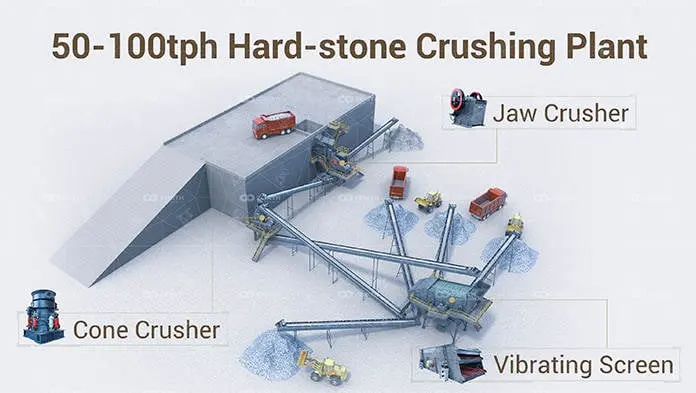

Introduction to Jaw Crushers

Jaw crushers are mechanical devices used to break down large rocks into smaller, more manageable pieces. They are commonly used in various industries for primary crushing applications. The primary components of a jaw crusher include:

- Jaw Plates: The surfaces that crush the material.

- Frame: The structure that supports the components.

- Eccentric Shaft: The rotating component that drives the movement of the jaw plates.

Role of the Eccentric Shaft

The eccentric shaft is pivotal to the operation of a jaw crusher. It is responsible for:

- Generating Motion: The shaft rotates, creating an elliptical motion that moves the jaw plates.

- Facilitating Crushing: The motion allows the jaw plates to compress and crush the material.

- Ensuring Efficiency: Proper functioning of the eccentric shaft ensures efficient crushing and energy consumption.

Design of the Eccentric Shaft

The design of the eccentric shaft is crucial for the effective operation of a jaw crusher. Key design aspects include:

- Material: Typically made from high-strength steel to withstand significant stress and wear.

- Shape: Usually cylindrical with an offset section to create the eccentric motion.

- Dimensions: Must be precisely engineered to fit within the crusher and provide the necessary motion.

Key Features

- Offset Center: The shaft is not perfectly centered, which creates the eccentric motion necessary for crushing.

- Bearings: Support the shaft and reduce friction during rotation.

- Balance: Proper balance is essential to minimize vibrations and wear.

Functioning of the Eccentric Shaft

The eccentric shaft operates through a series of coordinated actions:

- Rotation: Driven by a motor, the shaft rotates at a set speed.

- Motion Transfer: The rotation is transferred to the jaw plates, causing them to move in an elliptical pattern.

- Material Crushing: As the jaw plates move, they compress and break down the material into smaller pieces.

Maintenance and Troubleshooting

Proper maintenance of the eccentric shaft is essential for the longevity and efficiency of a jaw crusher. Key maintenance practices include:

- Regular Lubrication: Ensures smooth operation and reduces wear.

- Inspection: Regular checks for wear and damage can prevent failures.

- Alignment: Ensuring the shaft is properly aligned to avoid excessive vibrations.

Common Issues

- Wear and Tear: Over time, the shaft can wear down, affecting performance.

- Misalignment: Can cause uneven wear and potential failure.

- Bearing Failure: Bearings can wear out, leading to increased friction and potential shaft damage.

Conclusion

The eccentric shaft is a vital component of a jaw crusher, enabling the machine to perform its crushing function efficiently. Understanding its role, design, and maintenance is crucial for anyone involved in the operation or upkeep of jaw crushers. Proper care and attention to the eccentric shaft can significantly enhance the performance and lifespan of the crusher.