What is the functions of jaw crushers

సమయం:23 September 2025

Jaw crushers are essential equipment in the mining and construction industries, designed to reduce large rocks into smaller, manageable pieces. Their functionality is crucial in various applications, from aggregate production to mineral processing. This article explores the primary functions of jaw crushers, detailing their operation and significance.

Overview of Jaw Crushers

Jaw crushers are mechanical devices that use compressive force to break down materials. They consist of two jaws, one fixed and the other moving, which work together to crush materials.

కీ కంపోనెంట్స్

- Fixed Jaw: The stationary part of the crusher.

- Moving Jaw: The part that moves to exert force on the material.

- Pitman: Connects the moving jaw to the drive mechanism.

- Toggle Plates: Act as safety devices and adjust the movement of the jaws.

Primary Functions of Jaw Crushers

Jaw crushers serve several critical functions in industrial applications:

1. Material Reduction

The primary function of jaw crushers is to reduce the size of large rocks or ore. This is achieved through:

- సంకోచం: కదిలించే దిగ్బంధం, స్థిర దిగ్బంధానికి వ్యతిరేకంగా పదార్థాన్ని సంకోచిస్తుంది.

- Crushing Chamber: The space between the jaws where crushing occurs.

2. Size Classification

Jaw crushers help in classifying materials by size, ensuring uniformity in the output. This is crucial for subsequent processing stages:

- Adjustable Output Size: The crusher can be adjusted to produce different sizes of output material.

- Consistent Particle Size: Ensures efficiency in further processing.

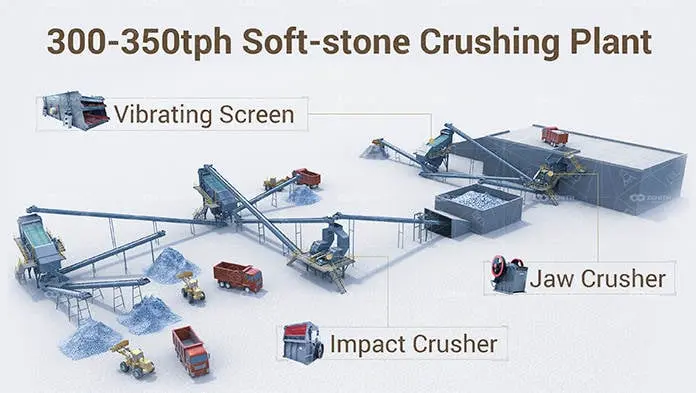

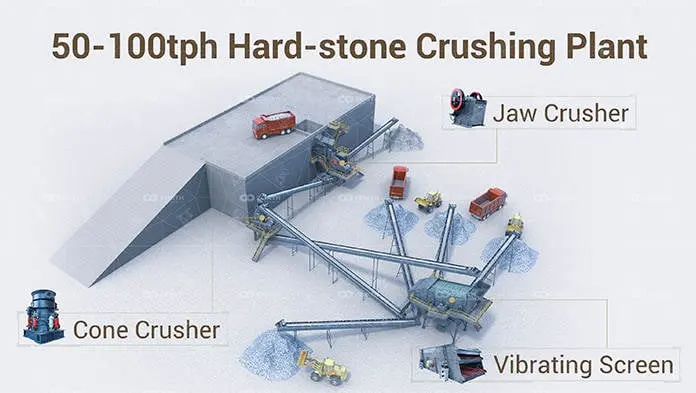

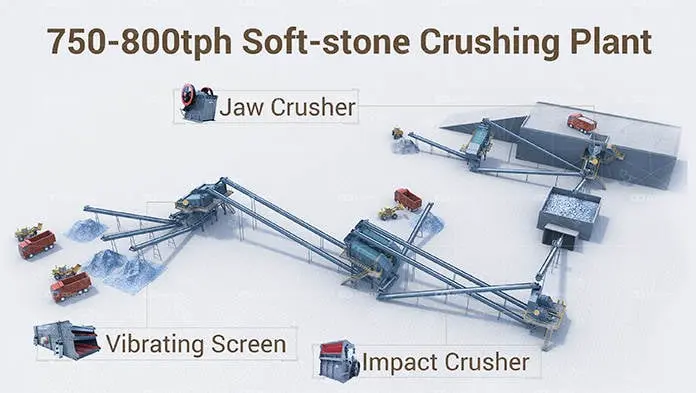

3. Preparation for Secondary Crushing

Jaw crushers often serve as the first step in a multi-stage crushing process. They prepare materials for secondary crushers, such as cone crushers or impact crushers:

- Initial Processing: Jaw crushers handle the initial reduction of material size.

- Feed Preparation: Ensures materials are appropriately sized for secondary crushing.

Operational Mechanism

Understanding the operational mechanism of jaw crushers is essential for optimizing their use:

Crushing Action

The crushing action in jaw crushers involves:

- మేటీ రక్తం: మెటీరియల్ ను క్రషర్ యొక్క పైభాగంలోకి పోస్తారు.

- Compression: The moving jaw exerts force on the material.

- Discharge: Crushed material exits through the bottom of the crusher.

శక్తి సమర్థత

Jaw crushers are designed to be energy-efficient, minimizing power consumption while maximizing output:

- Efficient Design: Features like toggle plates contribute to energy efficiency.

- Reduced Wear and Tear: Durable components extend the lifespan of the crusher.

Applications of Jaw Crushers

Jaw crushers are versatile and find applications in various industries:

ఖనిజ పరిశ్రమ

- Ore Processing: Essential for breaking down ores for mineral extraction.

- Aggregate Production: Produces gravel and sand for construction projects.

నిర్మాణ పరిశ్రమ

- Demolition Waste: Processes concrete and other demolition debris.

- Road Building: Provides materials for road construction.

జా క్రషర్ల పర్యావరణాలు

Jaw crushers offer several advantages that make them indispensable in industrial applications:

- Robust Construction: Built to withstand harsh conditions.

- High Throughput: Capable of processing large volumes of material.

- వివిధత: విస్తృత పరిధి పదార్థాలు మరియు అనువర్తనాల కోసం అనువైనది.

తీర్మానం

Jaw crushers are vital machines in the mining and construction sectors, performing essential functions that facilitate material processing. Their ability to reduce, classify, and prepare materials for further processing makes them indispensable in various industrial applications. Understanding their functions and operational mechanisms can help optimize their use, ensuring efficiency and longevity.