What are the cement mill pre-crushing equipment

Time:15 September 2025

Cement production is a complex process that involves various stages, one of which is the grinding of raw materials into a fine powder. This process is crucial for producing high-quality cement. Pre-crushing equipment plays a vital role in this stage by reducing the size of raw materials before they enter the cement mill. This article explores the different types of pre-crushing equipment used in cement mills.

Importance of Pre-Crushing in Cement Production

Pre-crushing is essential in cement production for several reasons:

- Efficiency Improvement: By reducing the size of raw materials, pre-crushing equipment enhances the efficiency of the grinding process.

- Energy Savings: Smaller particles require less energy to grind, leading to significant energy savings.

- Increased Mill Throughput: Pre-crushing helps in increasing the throughput of the cement mill by ensuring that the mill is fed with smaller, more manageable particles.

Types of Cement Mill Pre-Crushing Equipment

There are several types of pre-crushing equipment used in the cement industry, each with its unique features and advantages.

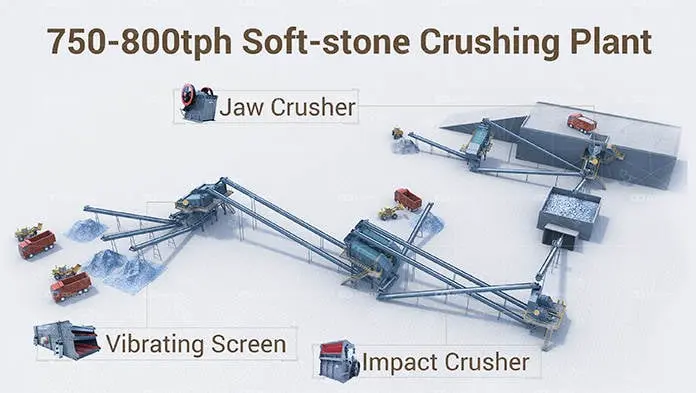

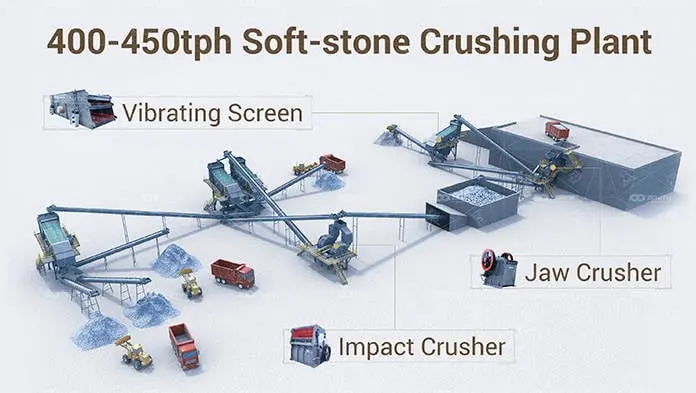

1. Jaw Crushers

Jaw crushers are commonly used as primary crushers in cement plants. They are designed to handle large, hard materials and reduce them to smaller sizes.

– Simple structure

– High crushing ratio

– Reliable operation

– Capable of handling large feed sizes

– Low operational and maintenance costs

2. Gyratory Crushers

Gyratory crushers are another type of primary crusher used in cement plants. They are suitable for crushing hard and abrasive materials.

– Continuous crushing action

– High throughput capacity

– Suitable for large-scale operations

– Produces a uniform particle size

3. Cone Crushers

Cone crushers are used for secondary crushing and are ideal for crushing medium to hard materials.

– High efficiency

– Adjustable product size

– Consistent product quality

– Versatile applications

4. Impact Crushers

Impact crushers are used for both primary and secondary crushing. They are particularly effective for materials with a low to medium hardness.

– High reduction ratio

– Ability to produce cubical-shaped particles

– Suitable for a wide range of materials

– Easy to maintain

5. Hammer Crushers

Hammer crushers are used for crushing medium-hard and soft materials such as limestone and gypsum.

– High production capacity

– Simple structure

– Low investment cost

– Suitable for materials with high moisture content

Selection Criteria for Pre-Crushing Equipment

Choosing the right pre-crushing equipment depends on several factors:

- Material Characteristics: The hardness, abrasiveness, and moisture content of the raw materials.

- Capacity Requirements: The required throughput and production capacity.

- Operational Considerations: Maintenance requirements, operational costs, and energy consumption.

- End Product Specifications: Desired particle size and shape of the crushed material.

Conclusion

Pre-crushing equipment is a critical component in the cement production process. By selecting the appropriate equipment, cement plants can enhance their efficiency, reduce energy consumption, and increase overall productivity. Understanding the different types of pre-crushing equipment and their features can help in making informed decisions that align with production goals and material characteristics.