what are the equipment in iron ore crusher

Time:15 September 2025

Equipment in Iron Ore Crusher

Iron ore crushers are essential in the mining and processing of iron ore. They are used to reduce the size of iron ore into smaller particles for further processing. This article provides a comprehensive overview of the equipment used in iron ore crushers, detailing their functions and importance in the crushing process.

Types of Iron Ore Crushers

Iron ore crushers come in various types, each serving a specific purpose in the crushing process:

- Jaw Crushers

– Used for primary crushing.

– Designed to handle large pieces of iron ore.

– Operate by compressing material between a fixed and a moving jaw.

- Cone Crushers

– Suitable for secondary and tertiary crushing.

– Crush iron ore by squeezing it between a gyrating spindle and an enclosing concave hopper.

– Provide high efficiency and uniform particle size.

- Impact Crushers

– Used for secondary crushing.

– Utilize impact force to break down iron ore.

– Ideal for producing finer particles.

- Gyratory Crushers

– Similar to jaw crushers but with a circular gap.

– Used for large-scale primary crushing.

– Offer continuous crushing action.

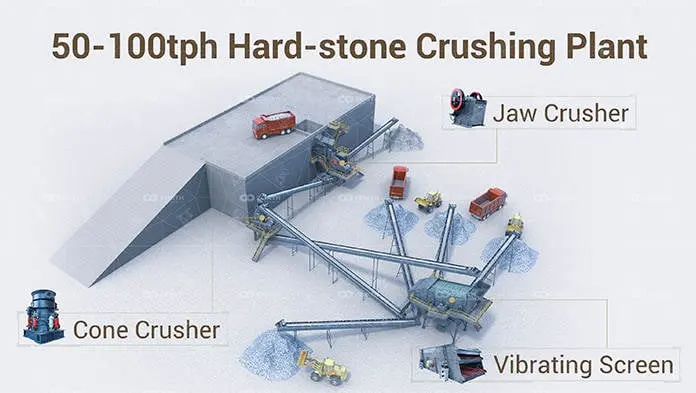

Key Equipment in Iron Ore Crushing Plant

A typical iron ore crushing plant includes several key pieces of equipment:

Primary Crushing Equipment

– Function: Breaks down large iron ore rocks into smaller pieces.

– Features: High capacity, robust construction, adjustable discharge settings.

Secondary Crushing Equipment

– Function: Further reduces iron ore size after primary crushing.

– Features: High crushing efficiency, adjustable settings for different sizes.

– Function: Provides finer crushing of iron ore.

– Features: High-speed rotors, wear-resistant materials.

Tertiary Crushing Equipment

- Vertical Shaft Impact (VSI) Crusher

– Function: Produces fine and uniform particles.

– Features: High-speed rotor, adjustable settings for particle size.

Supporting Equipment

In addition to crushers, several other pieces of equipment are essential for the efficient operation of an iron ore crushing plant:

Screening Equipment

– Function: Separates crushed iron ore into different size fractions.

– Features: Multiple layers, adjustable amplitude and frequency.

Conveying Equipment

– Function: Transports iron ore between different stages of crushing.

– Features: Durable belts, adjustable speed, and inclination.

Feeding Equipment

– Function: Ensures consistent and uniform feeding of iron ore into crushers.

– Features: Adjustable feeding rate, robust construction.

Importance of Equipment Selection

Selecting the right equipment for an iron ore crusher is crucial for optimizing the crushing process. Considerations include:

– Hardness, moisture content, and size distribution.

– Desired capacity, particle size, and quality.

– Energy consumption, maintenance needs, and cost-effectiveness.

Conclusion

Iron ore crushers are vital components in the mining industry, facilitating the processing of iron ore into usable materials. Understanding the different types of crushers and supporting equipment, along with their functions, helps in selecting the right machinery for efficient and effective ore processing. Proper equipment selection and maintenance ensure optimal performance and productivity in iron ore crushing operations.