What are the nickel smelting equipment

Time:16 September 2025

Nickel smelting is a critical process in the extraction and refining of nickel from its ores. The smelting process involves various stages and requires specialized equipment to efficiently extract nickel while minimizing environmental impact. This article provides a comprehensive overview of the equipment used in nickel smelting.

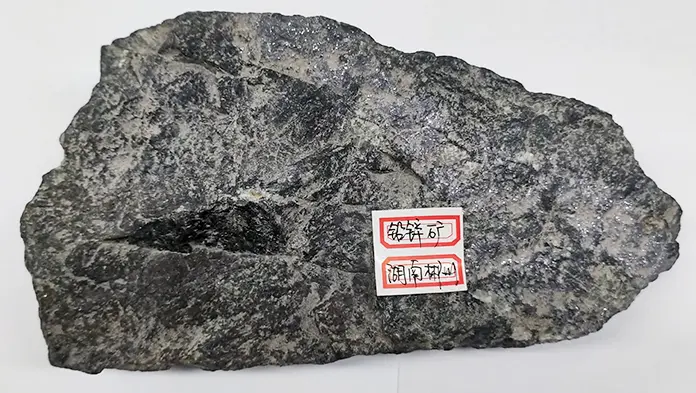

Overview of Nickel Smelting

Nickel smelting involves the extraction of nickel from its ores through a series of chemical reactions and physical processes. The primary objective is to separate nickel from other elements and impurities present in the ore. This is achieved through a combination of pyrometallurgical and hydrometallurgical techniques.

Key Equipment in Nickel Smelting

The smelting process involves several pieces of specialized equipment, each playing a crucial role in the extraction and refining of nickel.

1. Ore Feeders

Ore feeders are used to transport nickel ore from storage to the smelting furnace. They ensure a consistent and controlled flow of material, which is essential for maintaining optimal furnace operation.

- Vibratory Feeders: Utilize vibration to move ore along a conveyor.

- Belt Feeders: Use a continuous belt to transport ore.

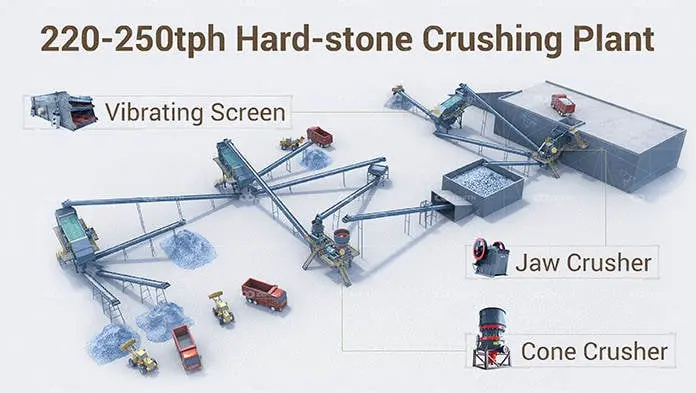

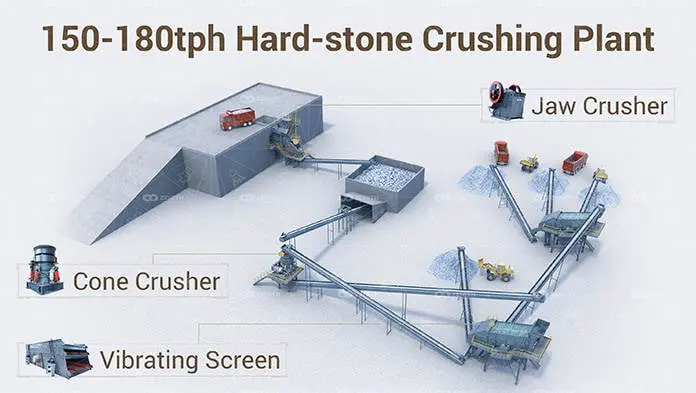

2. Crushing and Grinding Equipment

Before smelting, nickel ores must be crushed and ground to a fine powder to increase the surface area for the subsequent chemical reactions.

- Jaw Crushers: Used for the initial breaking down of large ore chunks.

- Ball Mills: Grind the crushed ore into a fine powder.

3. Roasting Furnaces

Roasting is a preliminary step where ore is heated in the presence of oxygen to remove sulfur and other volatile impurities.

- Fluidized Bed Roasters: Provide efficient heat transfer and uniform temperature distribution.

- Multiple Hearth Roasters: Consist of several hearths stacked vertically, allowing for continuous processing.

4. Smelting Furnaces

The core of the smelting process, these furnaces melt the ore to separate nickel from other elements.

- Electric Arc Furnaces: Use an electric arc to generate the high temperatures required for smelting.

- Flash Smelting Furnaces: Utilize the exothermic reaction of sulfur in the ore to provide the necessary heat.

5. Converters

Converters are used to further refine the molten material by blowing air or oxygen through it to remove impurities.

- Peirce-Smith Converters: The most common type, using tuyeres to inject air into the molten bath.

6. Refining Equipment

Refining equipment is used to purify nickel to the desired level of purity.

- Electrolytic Cells: Use electrolysis to refine nickel to high purity levels.

- Hydrometallurgical Leaching Tanks: Employ chemical solutions to dissolve impurities.

7. Environmental Control Systems

To minimize the environmental impact of smelting, various control systems are implemented.

- Baghouses: Capture particulate emissions from the furnace.

- Scrubbers: Remove sulfur dioxide and other gases from the exhaust.

Conclusion

Nickel smelting is a complex process that requires a range of specialized equipment to efficiently extract and refine nickel from its ores. From ore feeders to environmental control systems, each piece of equipment plays a vital role in ensuring the process is efficient, cost-effective, and environmentally friendly. Understanding the function and importance of each component is crucial for optimizing the smelting process and achieving high-quality nickel production.