What equipment do you need to start a quarry business

Time:23 September 2025

Starting a quarry business involves several critical steps and requires a range of equipment to ensure efficient operations. This article provides a comprehensive guide on the essential equipment needed to start a quarry business, covering everything from initial setup to ongoing operations.

Understanding Quarry Operations

Before delving into the specific equipment required, it’s important to understand the basic operations involved in a quarry business. Quarrying involves extracting rocks, sand, gravel, or other minerals from the ground to use them in construction or other industries. The process typically includes:

- Site preparation: Clearing the land and setting up necessary infrastructure.

- Extraction: Removing materials from the earth.

- Processing: Crushing, screening, and washing extracted materials.

- Transportation: Moving processed materials to their final destination.

Essential Equipment for Quarry Operations

1. Excavation Equipment

Excavation is the first step in quarrying operations. The following equipment is essential for efficient excavation:

- Excavators: Used for digging and removing overburden.

- Bulldozers: Ideal for clearing land and moving earth.

- Loaders: Useful for loading extracted materials onto trucks.

2. Drilling Equipment

Drilling is necessary to create holes for explosives used in breaking up large rocks. Essential drilling equipment includes:

- Drill rigs: Machines designed for drilling holes in the earth.

- Jackhammers: Used for smaller, more precise drilling tasks.

3. Blasting Equipment

Blasting is a critical process in quarrying, requiring specialized equipment:

- Explosives: Materials used to break apart rock formations.

- Detonators: Devices used to trigger explosives safely.

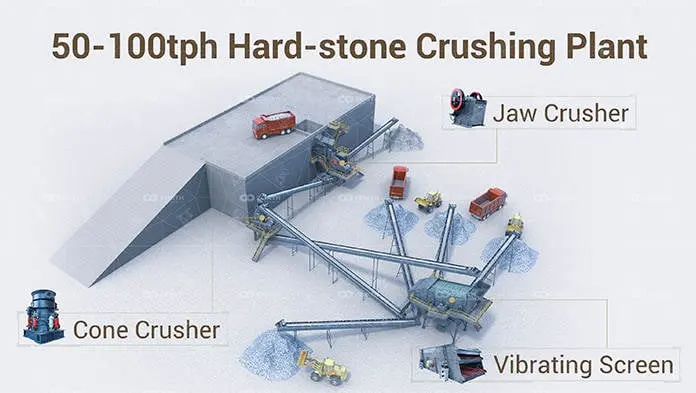

4. Crushing and Screening Equipment

Once materials are extracted, they need to be processed. Crushing and screening equipment is vital for this stage:

- Jaw crushers: Used for primary crushing of large rocks.

- Cone crushers: Ideal for secondary crushing.

- Impact crushers: Used for tertiary crushing.

- Vibrating screens: Separate materials based on size.

5. Conveying Equipment

Efficient transportation of materials within the quarry is crucial. Conveying equipment includes:

- Belt conveyors: Transport materials from one location to another.

- Stackers: Used for stacking processed materials.

6. Material Handling Equipment

Material handling equipment is essential for moving materials around the quarry:

- Dump trucks: Transport extracted and processed materials.

- Forklifts: Useful for moving pallets and other heavy items.

7. Safety Equipment

Safety is paramount in quarry operations. Essential safety equipment includes:

- Helmets and goggles: Protect workers from debris and dust.

- Ear protection: Necessary due to high noise levels.

- Safety boots: Protect feet from heavy equipment and falling objects.

Additional Considerations

Regulatory Compliance

Starting a quarry business requires compliance with local regulations and obtaining necessary permits. It’s crucial to:

- Research local laws: Understand zoning and environmental regulations.

- Obtain permits: Secure the necessary legal permissions to operate.

Environmental Impact

Quarry operations can have significant environmental impacts. Considerations include:

- Dust control: Implement measures to reduce airborne dust.

- Water management: Ensure proper drainage and water recycling.

Operational Efficiency

To maximize efficiency, consider:

- Equipment maintenance: Regularly service equipment to prevent breakdowns.

- Training: Ensure workers are trained in equipment operation and safety protocols.

Conclusion

Starting a quarry business requires a significant investment in equipment and infrastructure. By understanding the essential equipment needed for excavation, drilling, blasting, processing, and transportation, you can set up a successful operation. Additionally, adhering to regulatory requirements and prioritizing safety and environmental considerations will help ensure sustainable and efficient quarry operations.