What is mobile crushing plant and how it works crushing

Time:12 September 2025

Mobile crushing plants are versatile and efficient machines used in the mining and construction industries to crush and process materials on-site. This article explores what a mobile crushing plant is, its components, and how it works in the crushing process.

What is a Mobile Crushing Plant?

A mobile crushing plant is a portable and flexible piece of equipment designed to crush and screen materials directly at the site of extraction or construction. These plants are mounted on wheels or tracks, allowing them to be easily transported and relocated as needed.

Key Features

- Portability: Mobile crushing plants can be moved to different locations, reducing transportation costs and time.

- Flexibility: They can be configured to process various types of materials and adapt to different project requirements.

- Efficiency: Mobile plants streamline operations by eliminating the need to transport materials to a stationary crusher.

Components of a Mobile Crushing Plant

A typical mobile crushing plant consists of several key components:

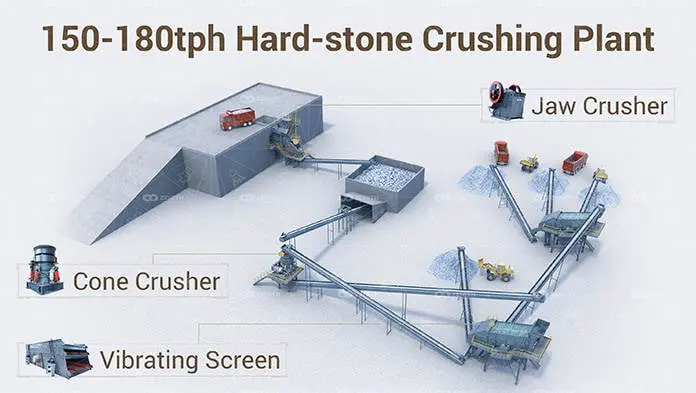

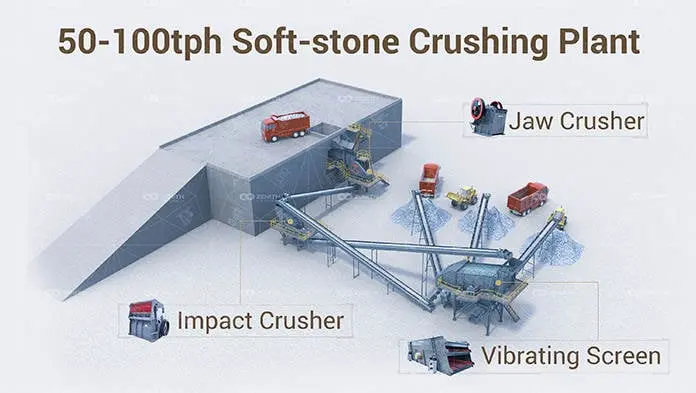

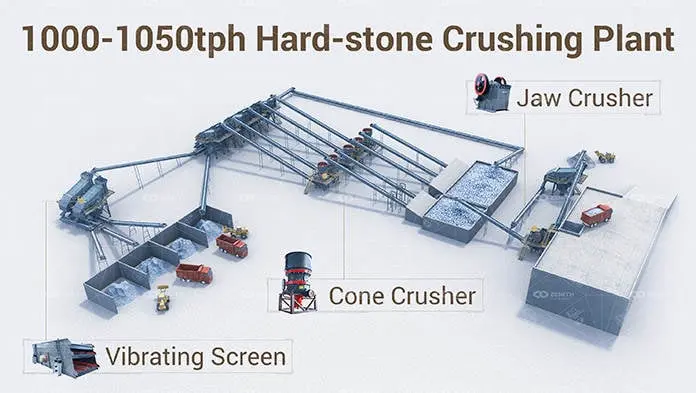

- Crusher: The primary component responsible for breaking down large rocks into smaller pieces. Types of crushers include jaw crushers, cone crushers, and impact crushers.

- Screening Unit: Separates crushed materials into different sizes for further processing or direct use.

- Conveyor Belts: Transport materials between different parts of the plant.

- Power Supply: Provides energy to operate the machinery, typically through diesel engines or electric motors.

- Control System: Manages the operation of the plant, ensuring optimal performance and safety.

How Mobile Crushing Plants Work

Mobile crushing plants operate by using mechanical force to break down materials. The process involves several stages:

1. Feeding

Materials are fed into the crusher using a hopper. The feeding mechanism ensures a consistent flow of material into the crushing chamber.

2. Crushing

Once inside the crusher, materials are subjected to intense pressure and impact, breaking them into smaller pieces. The type of crusher used determines the crushing method:

- Jaw Crusher: Utilizes compressive force to crush materials between two plates.

- Cone Crusher: Uses a rotating cone inside a fixed bowl to crush materials.

- Impact Crusher: Employs high-speed impact from a rotor to shatter materials.

3. Screening

After crushing, materials are transferred to the screening unit, where they are sorted by size. The screening process ensures that only appropriately sized materials proceed to the next stage.

4. Conveying

Conveyor belts transport the sorted materials to different areas of the plant or directly to storage or transport vehicles.

5. Final Processing

Depending on the project requirements, further processing may be needed, such as washing or additional crushing. The control system monitors and adjusts operations to maintain efficiency and safety.

Advantages of Mobile Crushing Plants

Mobile crushing plants offer several benefits:

- Reduced Transportation Costs: By processing materials on-site, transportation costs are minimized.

- Increased Efficiency: Projects can be completed faster due to the elimination of material transport delays.

- Environmental Benefits: Reduced need for transportation lowers emissions and environmental impact.

- Adaptability: Can be used in various applications, from mining to recycling.

Conclusion

Mobile crushing plants are essential tools in modern construction and mining operations. Their portability, efficiency, and adaptability make them ideal for processing materials directly at the site. Understanding their components and operation helps maximize their benefits and optimize project outcomes. Whether for large-scale mining or smaller construction projects, mobile crushing plants provide a practical solution for material processing needs.