What is the cost of a stone crusher plant

Time:12 September 2025

Stone crusher plants are integral to the construction and mining industries, providing essential materials for infrastructure development. Understanding the cost components involved in setting up and operating a stone crusher plant is crucial for businesses and investors. This article delves into the various factors influencing the cost of a stone crusher plant.

Factors Affecting the Cost

Several factors contribute to the overall cost of a stone crusher plant. These factors can vary based on location, size, and specific requirements of the project.

1. Initial Setup Costs

The initial setup costs include expenses related to the acquisition and installation of equipment and infrastructure. Key components include:

- Land Acquisition: The cost of purchasing or leasing land suitable for the plant.

- Equipment Purchase: Expenses related to buying crushers, conveyors, screens, and other machinery.

- Infrastructure Development: Costs for building foundations, electrical systems, and water supply.

2. Operational Costs

Operational costs are ongoing expenses required to keep the plant running efficiently. These include:

- Labor Costs: Salaries and wages for skilled and unskilled workers.

- Maintenance and Repairs: Regular maintenance and unexpected repairs for machinery.

- Utility Costs: Electricity, water, and fuel expenses.

- Raw Material Costs: The cost of acquiring raw materials for crushing.

3. Regulatory and Environmental Costs

Compliance with local regulations and environmental standards can impact costs significantly:

- Permits and Licenses: Fees for obtaining necessary operational permits.

- Environmental Compliance: Costs associated with implementing eco-friendly practices and technologies.

Cost Breakdown

To better understand the financial implications, let’s break down the costs into a structured format.

Initial Setup Costs

- Land Acquisition

– Purchase or lease costs

– Site preparation expenses

- Equipment Purchase

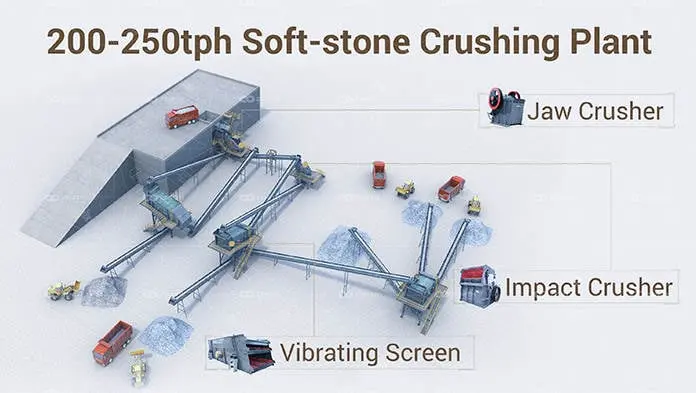

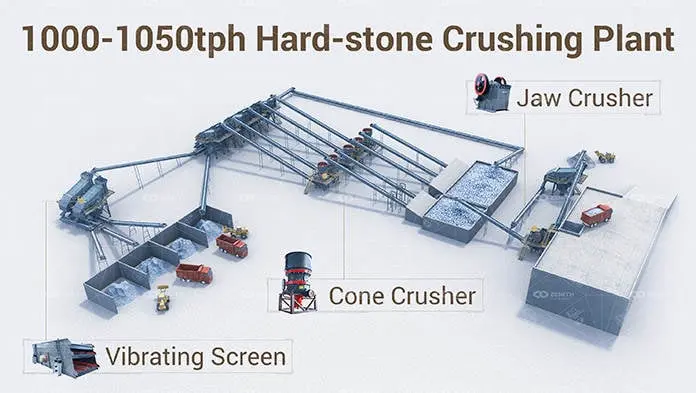

– Crushers (jaw, cone, impact)

– Conveyors and screens

– Ancillary equipment

- Infrastructure Development

– Foundation construction

– Electrical systems

– Water supply systems

Operational Costs

- Labor Costs

– Salaries for operators and technicians

– Training and development expenses

- Maintenance and Repairs

– Scheduled maintenance

– Spare parts inventory

- Utility Costs

– Electricity consumption

– Water usage

– Fuel for machinery

- Raw Material Costs

– Transportation and logistics

– Material procurement

Regulatory and Environmental Costs

- Permits and Licenses

– Application fees

– Renewal costs

- Environmental Compliance

– Waste management systems

– Pollution control technologies

Cost Estimation

Estimating the cost of a stone crusher plant involves considering all the aforementioned factors. Here is a simplified approach to estimate the total cost:

- Calculate Initial Setup Costs: Sum up expenses related to land, equipment, and infrastructure.

- Estimate Operational Costs: Consider monthly or annual expenses for labor, maintenance, utilities, and raw materials.

- Include Regulatory Costs: Factor in one-time and recurring costs for permits and environmental compliance.

Conclusion

The cost of a stone crusher plant is influenced by multiple factors, including initial setup, operational expenses, and regulatory requirements. By understanding these components, businesses can make informed decisions and plan their investments effectively. Careful budgeting and cost management are essential to ensure the profitability and sustainability of a stone crusher plant.