What is the functions of crusher

Time:12 September 2025

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand, or rock dust. Crushers are essential in the mining, construction, and recycling industries, where they are used to break down materials for further processing or for use in construction projects. This article explores the primary functions of crushers, their types, and their applications.

Primary Functions of a Crusher

Crushers serve several critical functions in various industries, including:

- Size Reduction: The primary function of a crusher is to reduce the size of large rocks or ore. This process makes it easier to handle and process materials.

- Material Separation: Crushers can separate different materials based on size and composition, which is crucial for recycling and waste management.

- Aggregate Production: In the construction industry, crushers are used to produce aggregates, which are essential components of concrete and asphalt.

- Facilitation of Material Handling: By reducing the size of materials, crushers make it easier to transport and manage them in subsequent processing stages.

Types of Crushers

There are several types of crushers, each designed for specific applications and material types. The most common types include:

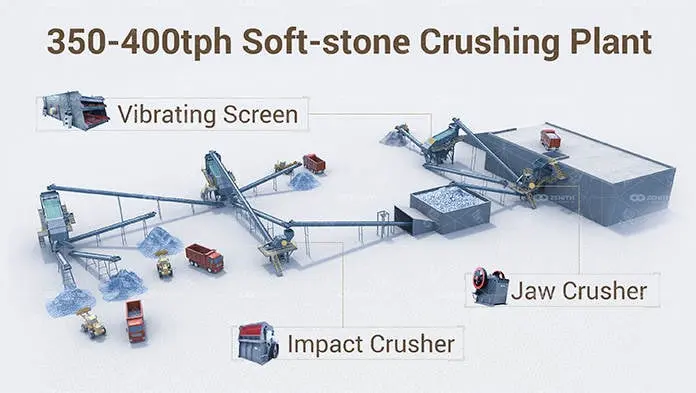

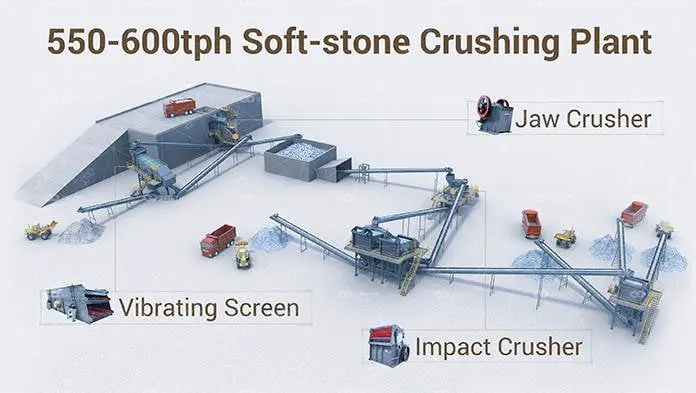

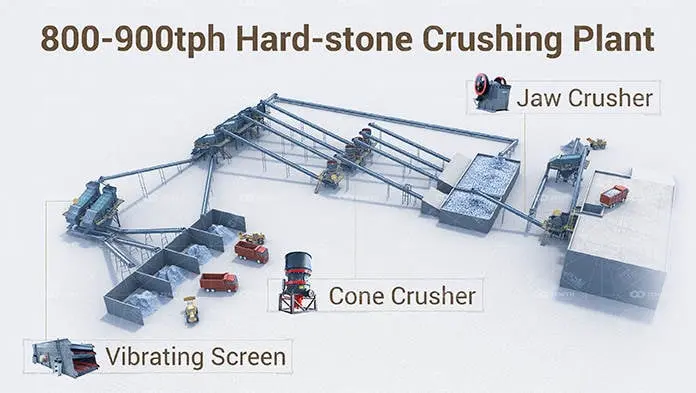

Jaw Crushers

- Function: Jaw crushers use compressive force to break down large materials into smaller, manageable pieces.

- Applications: Ideal for primary crushing of hard materials like granite and basalt.

Cone Crushers

- Function: Cone crushers use a rotating cone within a fixed outer shell to crush materials.

- Applications: Suitable for secondary and tertiary crushing stages, especially for medium to hard materials.

Impact Crushers

- Function: Impact crushers use high-speed impact force to fracture materials.

- Applications: Often used for softer materials like limestone and gypsum, and for recycling concrete and asphalt.

Gyratory Crushers

- Function: Similar to jaw crushers, but with a gyrating spindle that compresses materials.

- Applications: Used for primary crushing of large-scale mining operations.

Hammer Crushers

- Function: Hammer crushers use high-speed rotating hammers to crush materials.

- Applications: Suitable for brittle materials and for producing fine particles.

Applications of Crushers

Crushers are utilized in various industries, each with specific requirements and applications:

Mining Industry

- Ore Processing: Crushers are essential for breaking down ore into smaller pieces for further processing and extraction of minerals.

- Material Transport: Reduced material size facilitates easier transport and handling.

Construction Industry

- Aggregate Production: Crushers produce gravel, sand, and other aggregates used in concrete and asphalt.

- Demolition Waste Recycling: Crushers help recycle construction waste into reusable materials.

Recycling Industry

- Material Recovery: Crushers play a crucial role in recovering materials from waste, reducing landfill use.

- Metal Recovery: Specialized crushers can separate metals from other materials for recycling.

Conclusion

Crushers are indispensable tools in various industries, performing critical functions such as size reduction, material separation, and aggregate production. Understanding the different types of crushers and their specific applications allows for efficient and effective material processing, contributing to the success of mining, construction, and recycling operations. Whether in a quarry, a mine, or a recycling plant, crushers ensure that materials are processed efficiently and sustainably.