What is the price of barite crusher

Time:12 September 2025

Barite, a mineral composed of barium sulfate, is widely used in various industries, including oil and gas, chemical, and manufacturing. Crushing barite into smaller sizes is a crucial step in its processing, and a barite crusher is an essential piece of equipment in this process. Understanding the price of a barite crusher involves considering several factors, which we will explore in this article.

Factors Affecting the Price of a Barite Crusher

The price of a barite crusher can vary significantly based on several factors. Here are the primary considerations:

1. Type of Crusher

Different types of crushers are used for barite processing, and each type has its own price range:

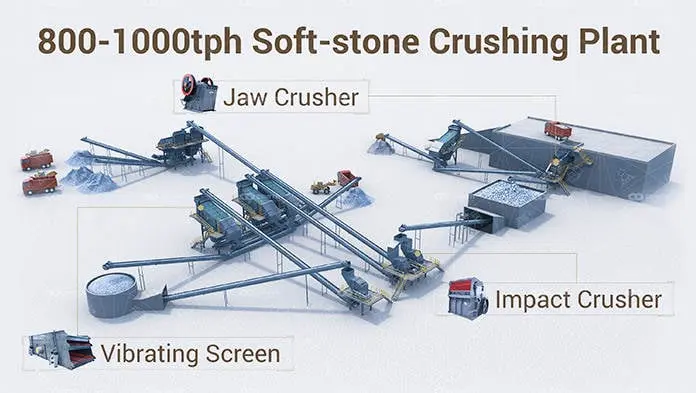

- Jaw Crushers: Known for their simplicity and durability. Typically used for primary crushing.

- Impact Crushers: Suitable for secondary crushing, offering high reduction ratios.

- Cone Crushers: Ideal for secondary and tertiary crushing, providing high efficiency and uniform particle size.

- Hammer Crushers: Used for medium to fine crushing, offering high production capacity.

2. Capacity

The capacity of the crusher, measured in tons per hour, directly influences the price. Higher capacity crushers are generally more expensive due to their ability to process larger volumes of material.

3. Brand and Manufacturer

The reputation and reliability of the manufacturer can impact the price. Well-known brands often charge a premium for their equipment due to perceived quality and after-sales support.

4. Features and Technology

Advanced features such as automation, ease of maintenance, and energy efficiency can increase the cost of a barite crusher. Crushers equipped with the latest technology tend to be more expensive.

5. Market Conditions

The price of raw materials, demand for barite, and economic factors can influence the overall cost of crushers. Market conditions can cause fluctuations in pricing.

Price Range of Barite Crushers

Based on the factors mentioned above, the price of barite crushers can vary widely. Here is a general price range for different types of crushers:

- Jaw Crushers: $10,000 – $100,000

- Impact Crushers: $15,000 – $120,000

- Cone Crushers: $20,000 – $150,000

- Hammer Crushers: $8,000 – $70,000

Note: These prices are approximate and can vary based on the specific model, manufacturer, and additional features.

Tips for Choosing the Right Barite Crusher

When selecting a barite crusher, consider the following tips to ensure you make an informed decision:

- Assess Your Needs: Determine the required capacity, particle size, and output specifications for your project.

- Research Manufacturers: Look for reputable manufacturers with positive reviews and a history of reliable equipment.

- Evaluate Features: Consider the features that are most important for your operation, such as automation and energy efficiency.

- Compare Prices: Obtain quotes from multiple suppliers to compare prices and features.

- Consider After-Sales Support: Ensure that the manufacturer offers adequate support and maintenance services.

Conclusion

The price of a barite crusher is influenced by various factors, including the type of crusher, capacity, brand, features, and market conditions. By understanding these factors and carefully evaluating your needs, you can select the right crusher that fits your budget and operational requirements. Always prioritize quality and reliability to ensure efficient and cost-effective barite processing.