What is the price of mobile crusher

Time:12 September 2025

Mobile crushers are essential equipment in the construction and mining industries, providing flexibility and efficiency in crushing operations. Understanding the price of mobile crushers involves considering various factors that influence their cost. This article provides a comprehensive overview of the factors affecting the price of mobile crushers, the types available, and considerations for purchasing.

Factors Affecting the Price of Mobile Crushers

Several factors contribute to the pricing of mobile crushers. These include:

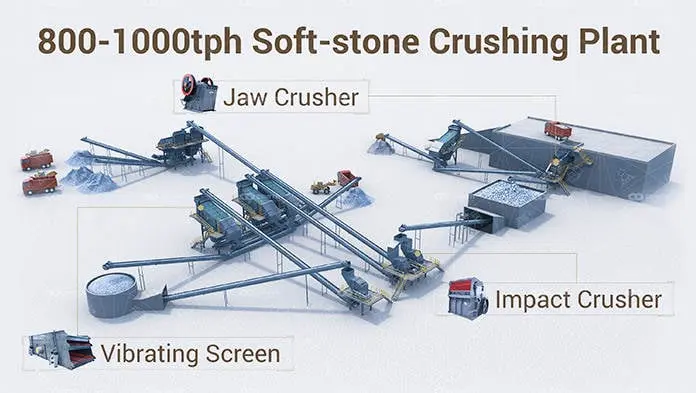

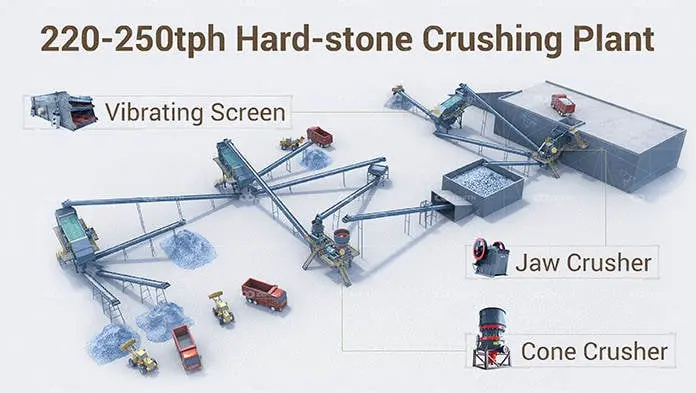

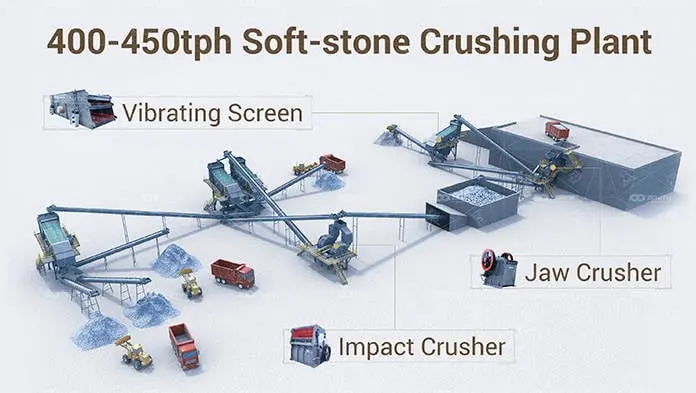

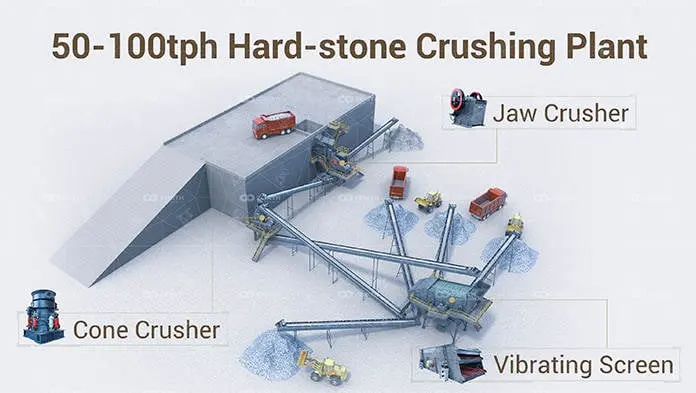

- Type of Crusher: Different types of crushers, such as jaw crushers, cone crushers, and impact crushers, have varying prices.

- Capacity: The output capacity of the crusher significantly affects its price. Higher capacity crushers are generally more expensive.

- Technology and Features: Advanced technology and additional features such as automation, remote control, and enhanced safety measures can increase the cost.

- Brand and Manufacturer: Well-known brands and reputable manufacturers often charge a premium for their products due to perceived reliability and quality.

- Market Demand: Prices can fluctuate based on market demand and supply dynamics.

- Condition: New crushers are more expensive than used ones, but used crushers can offer cost savings if they are in good condition.

Types of Mobile Crushers

Mobile crushers come in different types, each suited for specific applications and varying in price:

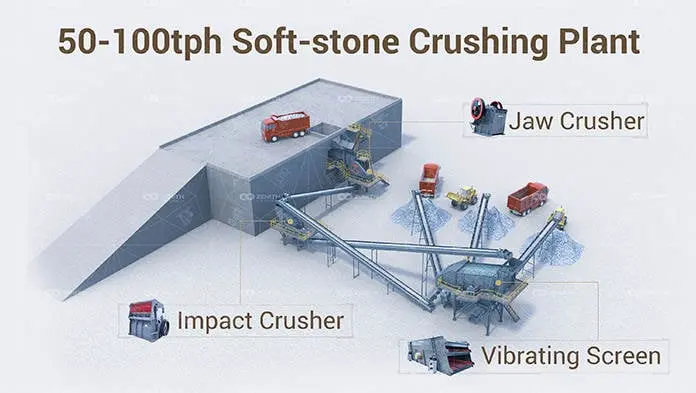

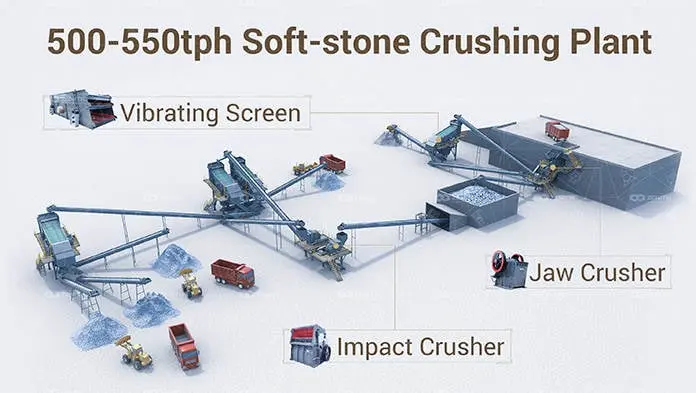

Jaw Crushers

- Function: Used for primary crushing of large materials.

- Price Range: Typically mid-range compared to other types.

Cone Crushers

- Function: Suitable for secondary and tertiary crushing.

- Price Range: Generally higher due to their ability to produce finer material.

Impact Crushers

- Function: Ideal for crushing softer materials and recycling applications.

- Price Range: Varies widely based on capacity and features.

Price Considerations

When evaluating the price of mobile crushers, consider the following:

1. Total Cost of Ownership

- Initial Purchase Price: The upfront cost of the crusher.

- Operating Costs: Includes maintenance, fuel, and labor costs.

- Resale Value: Consider the potential resale value when upgrading or selling the equipment.

2. Financing Options

- Leasing: Offers flexibility and lower initial costs.

- Loans: May provide favorable terms depending on the lender.

3. Warranty and Service Agreements

- Warranty: Check the warranty terms to ensure coverage for repairs and replacements.

- Service Agreements: Consider service agreements for regular maintenance and support.

Purchasing Tips

When purchasing a mobile crusher, keep these tips in mind:

- Assess Your Needs: Determine the type and capacity of crusher required for your specific application.

- Research Brands: Compare different brands and models to find the best fit for your budget and requirements.

- Inspect Used Equipment: If considering a used crusher, thoroughly inspect its condition and history.

- Negotiate: Don’t hesitate to negotiate the price and terms with the seller or dealer.

Conclusion

The price of mobile crushers varies widely based on several factors, including type, capacity, features, and market conditions. By understanding these factors and considering the total cost of ownership, buyers can make informed decisions that align with their operational needs and budget constraints. Whether purchasing new or used, careful evaluation and negotiation can lead to a cost-effective investment in mobile crushing equipment.