What machines are required for a limestone powder factory

Time:12 September 2025

Setting up a limestone powder factory involves a series of processes that require specialized machinery. Each machine plays a crucial role in transforming raw limestone into fine powder suitable for various industrial applications. This article provides a comprehensive overview of the essential machines required for a limestone powder factory.

1. Raw Material Handling

1.1. Excavators

- Purpose: Used for extracting limestone from quarries.

- Features: Equipped with powerful hydraulic arms and buckets for efficient digging.

1.2. Dump Trucks

- Purpose: Transport raw limestone from the quarry to the processing plant.

- Features: High-capacity beds for carrying large volumes of material.

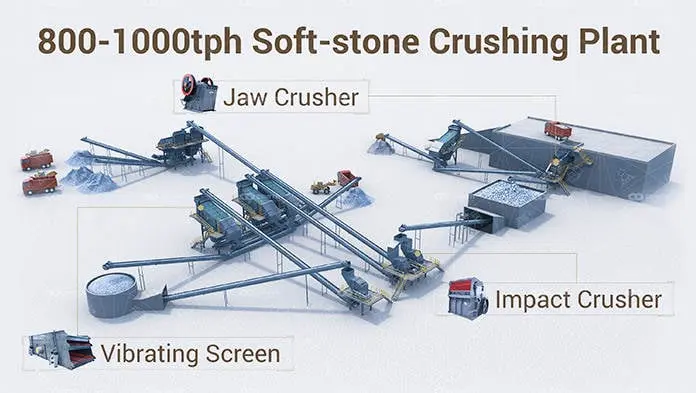

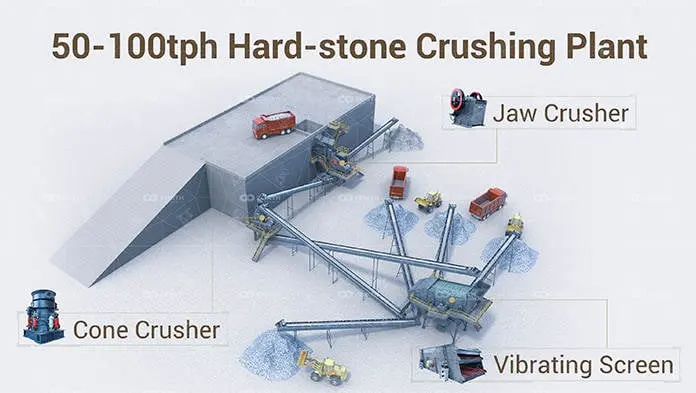

2. Crushing Equipment

2.1. Jaw Crusher

- Purpose: Primary crushing of large limestone rocks.

- Features:

– High crushing ratio

– Robust construction

– Adjustable discharge opening for varying output sizes

2.2. Impact Crusher

- Purpose: Secondary crushing to achieve finer limestone particles.

- Features:

– High reduction ratio

– Ability to handle materials with varying hardness

3. Grinding Equipment

3.1. Raymond Mill

- Purpose: Grinding limestone into fine powder.

- Features:

– High efficiency and low energy consumption

– Adjustable fineness of the final product

3.2. Ball Mill

- Purpose: Further grinding of limestone powder for finer consistency.

- Features:

– Suitable for both dry and wet grinding

– High capacity and uniform particle size distribution

4. Classification Equipment

4.1. Air Classifier

- Purpose: Separates fine limestone powder from coarser particles.

- Features:

– Adjustable cut size

– High precision and efficiency

5. Dust Collection Systems

5.1. Baghouse Filter

- Purpose: Collects dust generated during the crushing and grinding processes.

- Features:

– High filtration efficiency

– Easy maintenance and operation

5.2. Cyclone Dust Collector

- Purpose: Pre-collection of large dust particles.

- Features:

– Simple design

– Low operational cost

6. Conveying Systems

6.1. Belt Conveyor

- Purpose: Transports limestone between different processing stages.

- Features:

– Durable and reliable

– Adjustable speed and inclination

7. Packaging Equipment

7.1. Automatic Packing Machine

- Purpose: Packages the final limestone powder product for distribution.

- Features:

– High-speed operation

– Accurate weighing and sealing

8. Auxiliary Equipment

8.1. Vibrating Feeder

- Purpose: Feeds limestone into crushers and mills evenly.

- Features:

– Adjustable feeding rate

– Reliable and stable operation

8.2. Control System

- Purpose: Monitors and controls the entire production process.

- Features:

– User-friendly interface

– Real-time data monitoring and analysis

Conclusion

Establishing a limestone powder factory requires a range of specialized machines to ensure efficient and high-quality production. From raw material handling to final packaging, each piece of equipment plays a vital role in the overall process. By investing in the right machinery, manufacturers can optimize production, reduce costs, and meet market demands effectively.