what profits from crusher machine in kenya

Time:16 September 2025

Crusher machines are essential in the mining and construction industries, particularly in Kenya, where they play a significant role in processing raw materials. Understanding the profitability of crusher machines involves analyzing various factors, including market demand, operational costs, and economic impact.

Overview of Crusher Machines

Crusher machines are used to break down large rocks into smaller, manageable pieces. They are crucial in the production of aggregates, which are used in construction projects such as roads, bridges, and buildings.

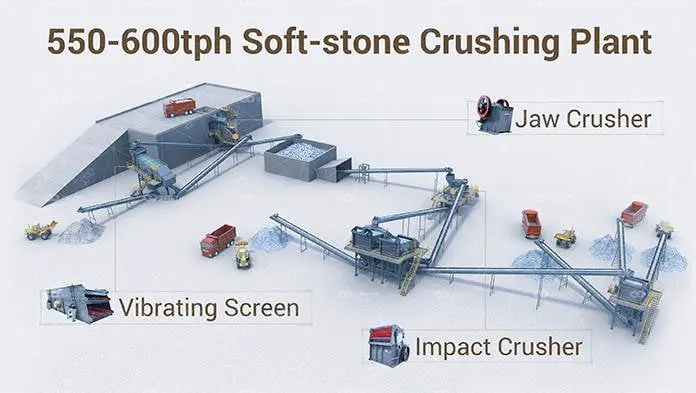

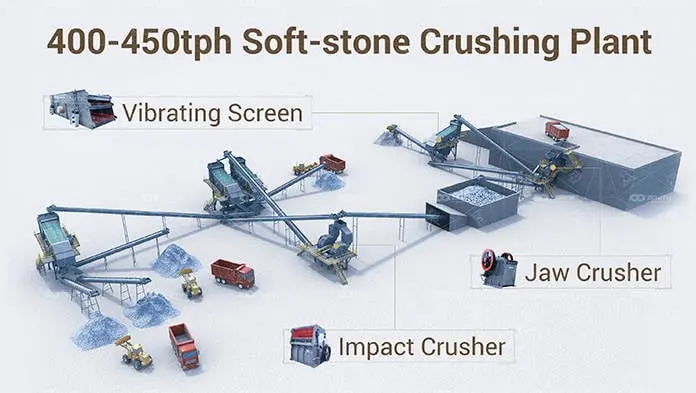

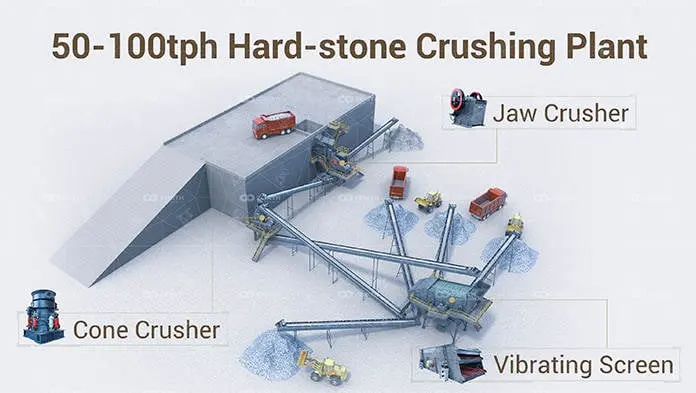

Types of Crusher Machines

- Jaw Crushers: Used for primary crushing of large rocks.

- Cone Crushers: Suitable for secondary crushing.

- Impact Crushers: Used for tertiary crushing and producing finer materials.

- Hammer Crushers: Ideal for softer materials.

Factors Influencing Profits

Several factors determine the profitability of crusher machines in Kenya:

Market Demand

- Construction Boom: Increased infrastructure projects boost demand for aggregates.

- Urbanization: Growing cities require more construction materials.

- Mining Industry: Demand for minerals and ores influences crusher machine utilization.

Operational Costs

- Initial Investment: Cost of purchasing and installing crusher machines.

- Maintenance: Regular servicing to ensure efficiency and longevity.

- Labor Costs: Skilled workforce required for operation and maintenance.

- Energy Consumption: Crushers are energy-intensive, impacting overall costs.

Economic Impact

- Local Economy: Crusher machines contribute to local economic growth by providing jobs and supporting construction projects.

- Export Opportunities: High-quality aggregates can be exported, increasing revenue.

Calculating Profitability

To determine the profitability of crusher machines, consider the following:

Revenue Generation

- Sales Volume: Quantity of aggregates sold.

- Price Per Unit: Market price for different types of aggregates.

- Additional Services: Offering transport and delivery services for aggregates.

Cost Analysis

- Fixed Costs: Initial setup and depreciation.

- Variable Costs: Operational expenses, including labor and maintenance.

Profit Margin

Calculate the profit margin using the formula:

\[ \text{Profit Margin} = \left( \frac{\text{Total Revenue} – \text{Total Costs}}{\text{Total Revenue}} \right) \times 100 \]

Strategies to Enhance Profits

To maximize profits from crusher machines, consider the following strategies:

Efficiency Improvements

- Upgrade Equipment: Invest in modern, energy-efficient crushers.

- Optimize Operations: Implement best practices for crushing processes.

Market Expansion

- Diversification: Expand product offerings to include different aggregate sizes and types.

- Partnerships: Collaborate with construction companies for long-term contracts.

Cost Management

- Energy Savings: Utilize renewable energy sources to reduce costs.

- Preventive Maintenance: Regular checks to avoid costly repairs.

Conclusion

Profits from crusher machines in Kenya are influenced by market demand, operational costs, and economic factors. By understanding these elements and implementing strategic measures, businesses can enhance their profitability and contribute to the country’s development. Investing in efficient equipment, expanding market reach, and managing costs effectively are key to maximizing returns in this industry.