What raw materials and equipment are needed for artificial sand

Time:12 September 2025

Artificial sand, also known as manufactured sand, is increasingly used in construction due to the depletion of natural sand resources. This article outlines the essential raw materials and equipment required for artificial sand production.

Raw Materials Needed for Artificial Sand

The production of artificial sand involves the transformation of raw materials into fine aggregates. The primary raw materials include:

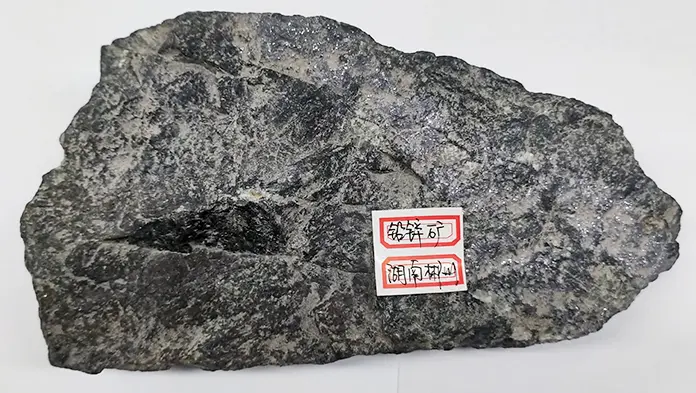

1. Rock Types

Various rock types can be utilized to produce artificial sand. The choice of rock depends on the desired properties of the sand, such as strength and durability.

- Granite: Known for its hardness and durability, granite is a preferred choice for high-strength applications.

- Basalt: Offers excellent mechanical properties and is suitable for concrete applications.

- Limestone: Provides good workability and is often used in construction projects.

- Quartzite: Known for its high silica content, quartzite is ideal for producing sand with high resistance to weathering.

2. Additives

To enhance the properties of artificial sand, certain additives may be incorporated:

- Binders: Cement or lime can be added to improve cohesion.

- Plasticizers: These are used to enhance the workability of the sand.

- Colorants: Pigments may be added for aesthetic purposes.

Equipment Required for Artificial Sand Production

The production process of artificial sand involves several stages, each requiring specific equipment. Below is a list of essential equipment:

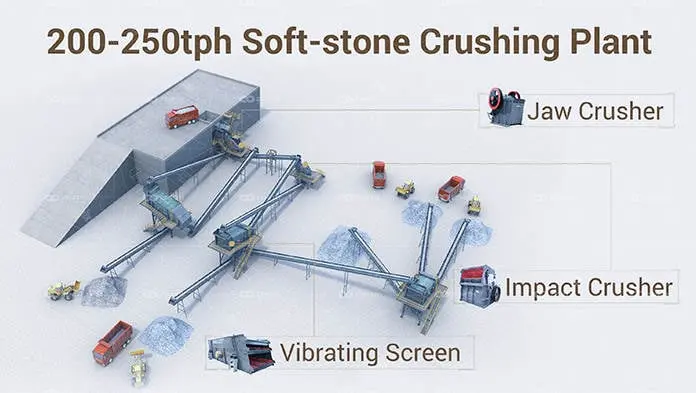

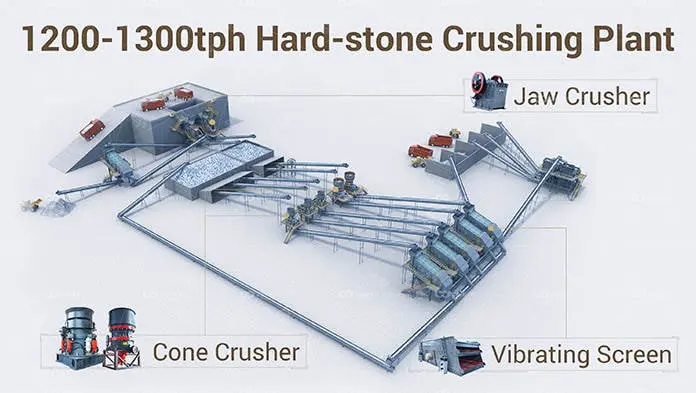

1. Crushing Equipment

Crushing equipment is used to break down large rocks into smaller particles suitable for sand production.

- Jaw Crushers: Used for primary crushing of large rocks.

- Cone Crushers: Suitable for secondary crushing and producing finer aggregates.

- Impact Crushers: Ideal for achieving a high reduction ratio and producing sand-like particles.

2. Screening Equipment

Screening equipment is crucial for separating sand particles based on size.

- Vibrating Screens: Used to classify sand particles into different sizes.

- Rotary Screens: Provide efficient separation and grading.

3. Washing Equipment

Washing equipment ensures the removal of impurities and enhances the quality of the sand.

- Sand Washers: Remove clay, silt, and other contaminants from sand particles.

- Hydrocyclones: Used for efficient separation of fine particles and water.

4. Conveying Equipment

Conveying systems are essential for transporting materials between different stages of production.

- Belt Conveyors: Facilitate the movement of materials across production stages.

- Bucket Elevators: Used for vertical transportation of materials.

5. Storage and Packaging Equipment

Proper storage and packaging are vital for maintaining the quality of artificial sand.

- Silos: Used for storing large volumes of sand.

- Bagging Machines: Facilitate the packaging of sand for distribution.

Conclusion

The production of artificial sand requires a comprehensive understanding of the raw materials and equipment involved. By selecting the appropriate rock types and utilizing advanced machinery, manufacturers can produce high-quality sand that meets the demands of modern construction projects. The integration of additives further enhances the properties of artificial sand, making it a viable alternative to natural sand.