What type of crusher is used for iron ore

Time:12 September 2025

Iron ore is a critical raw material used in the production of steel, and its processing requires specialized equipment to ensure efficiency and effectiveness. Crushers play a pivotal role in this process by reducing the size of the ore, making it easier to handle and process further. This article explores the various types of crushers used for iron ore, their applications, and their advantages.

Types of Crushers Used for Iron Ore

Several types of crushers are utilized in the mining and processing of iron ore. Each type has its unique characteristics and is chosen based on the specific requirements of the operation.

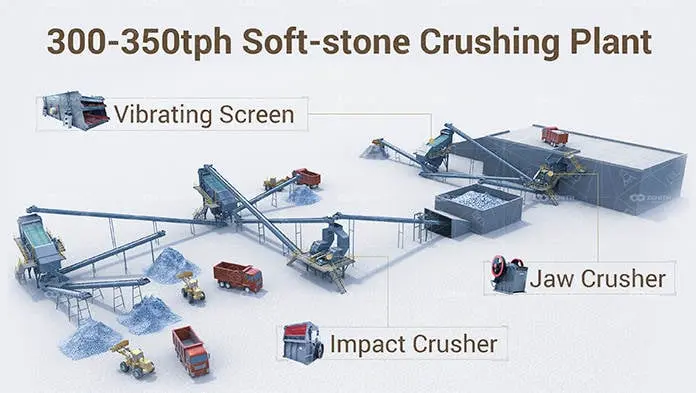

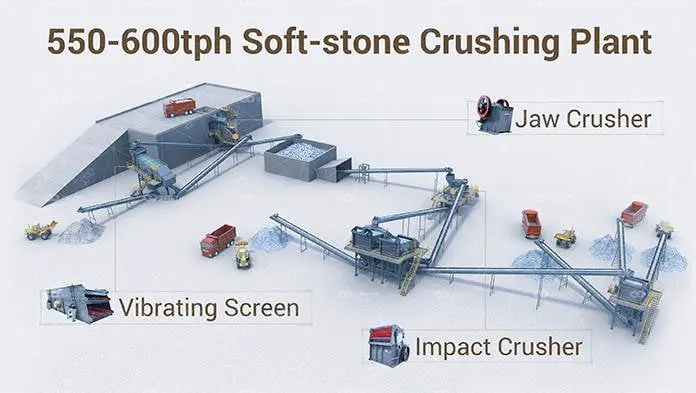

1. Jaw Crushers

Jaw crushers are commonly used as primary crushers in mining operations. They are designed to handle large rocks and break them down into smaller pieces.

– High capacity and efficiency.

– Simple structure and easy maintenance.

– Suitable for crushing hard materials like iron ore.

– Ideal for primary crushing of iron ore.

– Used in both surface and underground mining operations.

2. Gyratory Crushers

Gyratory crushers are another type of primary crusher used in iron ore processing. They operate on a similar principle to jaw crushers but have a conical head.

– High throughput capacity.

– Capable of handling very hard and abrasive materials.

– Continuous operation with minimal downtime.

– Suitable for large-scale iron ore mining operations.

– Often used in conjunction with jaw crushers for optimal results.

3. Cone Crushers

Cone crushers are used for secondary and tertiary crushing stages. They are ideal for reducing the size of iron ore after it has been initially crushed.

– High efficiency and low energy consumption.

– Produces a uniform particle size.

– Versatile and adaptable to various crushing stages.

– Used after primary crushers to achieve finer particle sizes.

– Suitable for both wet and dry processing of iron ore.

4. Impact Crushers

Impact crushers are less commonly used for iron ore but can be effective in certain applications, particularly where the ore is not overly abrasive.

– High reduction ratios.

– Ability to produce fine particles.

– Can handle soft to medium-hard materials.

– Used in some secondary crushing applications.

– Suitable for ores with lower hardness levels.

Factors Influencing Crusher Selection

When selecting a crusher for iron ore processing, several factors must be considered to ensure the chosen equipment meets the operational requirements.

Ore Characteristics

- Hardness: Harder ores require more robust crushers like jaw or gyratory crushers.

- Moisture Content: High moisture content can affect the performance of certain crushers, particularly impact crushers.

Production Requirements

- Capacity: The crusher must be able to handle the desired throughput.

- Particle Size: The desired final particle size will influence the type of crusher used.

Operational Considerations

- Maintenance: Crushers that are easy to maintain and have low downtime are preferred.

- Energy Efficiency: Energy-efficient crushers can reduce operational costs.

Conclusion

Choosing the right type of crusher for iron ore is crucial to the efficiency and success of mining operations. Jaw crushers and gyratory crushers are typically used for primary crushing, while cone crushers are preferred for secondary and tertiary stages. Impact crushers may be used in specific scenarios where the ore characteristics allow. By considering factors such as ore characteristics, production requirements, and operational considerations, mining operations can select the most suitable crusher to optimize their processing activities.