What is the difference between mining and crushing

Time:23 September 2025

Understanding the processes involved in the extraction and processing of minerals is crucial for industries such as construction, metallurgy, and manufacturing. Two fundamental operations in this context are mining and crushing. While they are interconnected, they serve distinct purposes and involve different techniques and equipment.

Mining

Mining is the process of extracting valuable minerals or other geological materials from the earth. It is a comprehensive operation that involves several stages, each crucial for the successful recovery of resources.

Key Stages of Mining

– Involves the search for mineral deposits.

– Utilizes geological surveys, sampling, and drilling.

– The actual removal of minerals from the earth.

– Techniques used include:

– Surface mining: Open-pit mining, strip mining.

– Underground mining: Shaft mining, drift mining.

– Separating valuable minerals from waste material.

– Methods include:

– Flotation

– Leaching

– Smelting

Types of Mining

– Involves removing soil and rock overlying the mineral deposit.

– Efficient for large, shallow deposits.

– Involves creating tunnels or shafts to access mineral deposits.

– Suitable for deep deposits.

Crushing

Crushing is the process of reducing the size of materials, typically after mining, to facilitate further processing or to meet specific size requirements. It is a critical step in mineral processing.

Objectives of Crushing

– Achieving the desired particle size for further processing.

– Freeing valuable minerals from the surrounding rock matrix.

Crushing Techniques

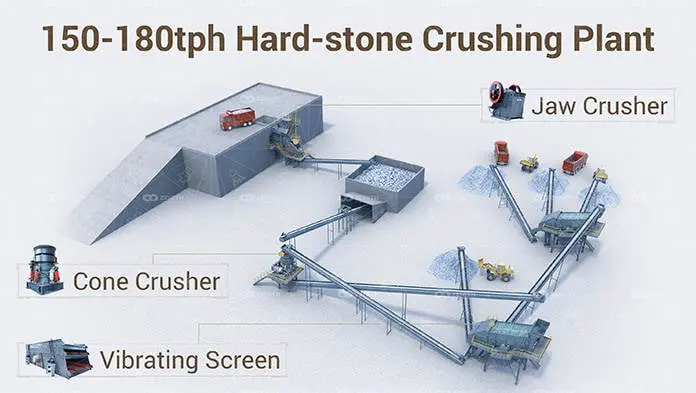

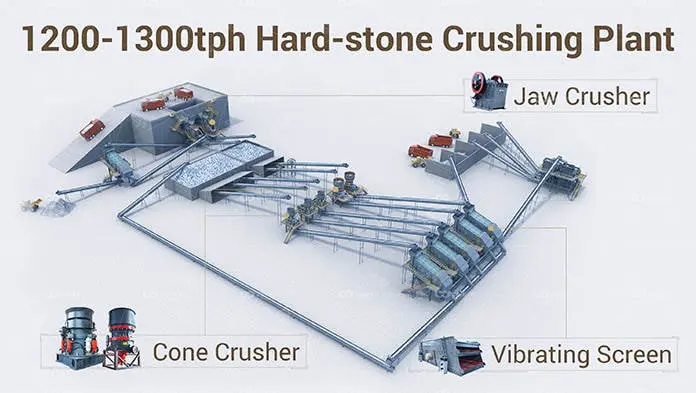

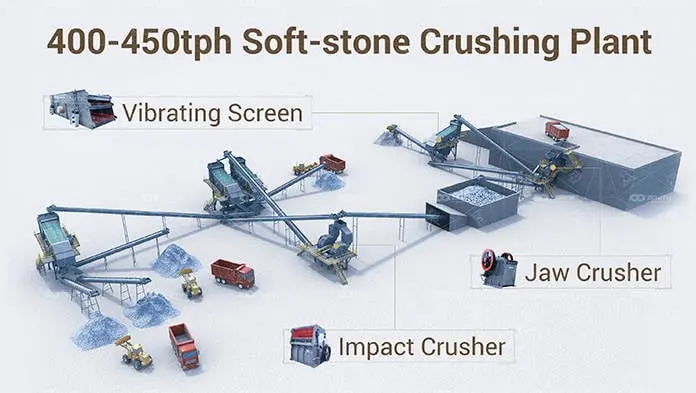

- Primary Crushing

– Initial stage of crushing.

– Utilizes heavy-duty machines like jaw crushers and gyratory crushers.

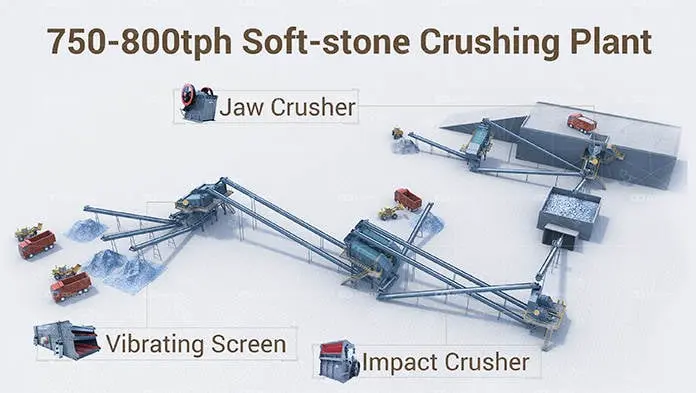

- Secondary Crushing

– Further reduces material size.

– Employs cone crushers and impact crushers.

- Tertiary Crushing

– Final stage of crushing.

– Achieves fine particle sizes using specialized equipment like ball mills.

Types of Crushers

– Use compressive force for breaking materials.

– Suitable for large and hard materials.

– Utilize a rotating cone inside a stationary shell.

– Ideal for secondary crushing.

– Use impact force to break materials.

– Effective for softer materials.

Key Differences Between Mining and Crushing

– Mining is focused on extracting minerals from the earth.

– Crushing is aimed at reducing material size for processing.

– Mining involves exploration, extraction, and processing.

– Crushing involves size reduction and liberation.

– Mining uses drills, excavators, and loaders.

– Crushing employs crushers and mills.

– Mining results in raw mineral deposits.

– Crushing produces smaller, processable material sizes.

Conclusion

Both mining and crushing are integral to the mineral extraction industry, each serving unique roles in the journey from raw earth materials to usable products. Understanding the differences between these processes helps in optimizing operations and improving efficiency in mineral processing.