What are equipments used in a cement plant

Time:12 September 2025

Cement plants are complex industrial facilities that require a variety of equipment to produce cement efficiently. This article provides a detailed overview of the essential equipment used in cement manufacturing, highlighting their functions and importance in the production process.

1. Raw Material Extraction and Preparation

The first stage in cement production involves the extraction and preparation of raw materials. The primary raw materials include limestone, clay, and sand. The equipment used in this stage includes:

- Excavators and Loaders: Used for extracting raw materials from quarries.

- Dump Trucks: Transport raw materials to the crushing area.

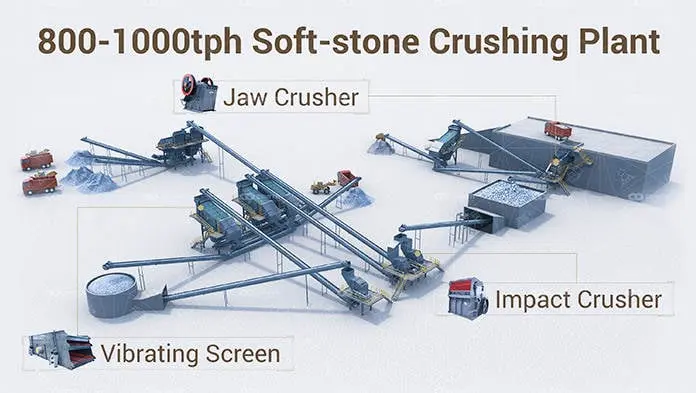

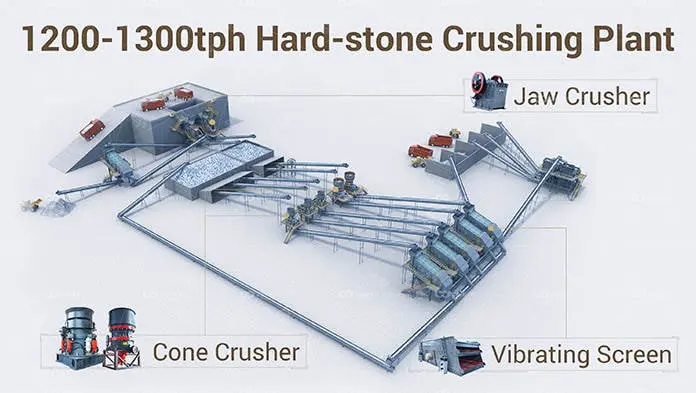

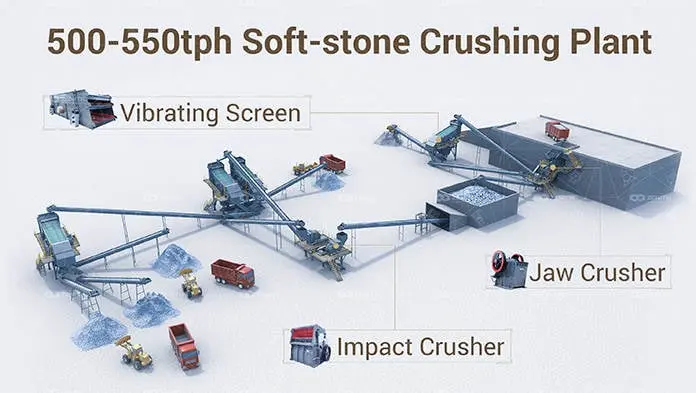

- Crushers: Reduce the size of raw materials to facilitate further processing. Types include:

– Jaw Crushers

– Gyratory Crushers

– Impact Crushers

2. Raw Material Grinding

Once extracted, raw materials need to be ground into a fine powder. This process is crucial for the subsequent chemical reactions. Equipment used includes:

- Ball Mills: Cylindrical devices that grind materials using steel balls.

- Vertical Roller Mills: Use large rollers to crush and grind materials.

- Hammer Mills: Employ hammers to shatter and grind materials.

3. Material Blending and Storage

After grinding, the raw materials are blended to ensure a uniform chemical composition. Key equipment includes:

- Blending Silos: Large storage tanks that mix raw materials thoroughly.

- Conveyors: Transport materials between different stages of production.

4. Clinker Production

Clinker production is the heart of the cement manufacturing process. It involves heating the raw mix to high temperatures in a kiln. Equipment used in this stage includes:

- Rotary Kilns: Large cylindrical furnaces that rotate to facilitate even heating.

- Preheaters and Precalciners: Improve energy efficiency by partially heating raw materials before they enter the kiln.

- Coolers: Rapidly cool the clinker to stabilize its chemical structure.

5. Cement Grinding

The cooled clinker is ground to a fine powder and mixed with gypsum to produce cement. Equipment used includes:

- Cement Mills: Similar to raw material mills, these grind clinker into cement.

- Separators: Classify cement particles by size to ensure uniformity.

6. Packaging and Dispatch

The final stage involves packaging the cement and preparing it for distribution. Equipment includes:

- Packing Machines: Automatically fill bags with cement and seal them.

- Palletizers: Stack bags onto pallets for easy transport.

- Conveyor Belts: Move packaged cement to storage or loading areas.

7. Auxiliary Equipment

In addition to the primary equipment, several auxiliary systems support cement production:

- Dust Collectors: Capture dust and particulates to maintain air quality.

- Fans and Blowers: Provide airflow for combustion and material transport.

- Water Treatment Systems: Ensure water used in the process is treated and recycled.

Conclusion

The equipment used in a cement plant is vital for efficient and sustainable production. Each piece of equipment plays a specific role, contributing to the overall quality and consistency of the cement produced. Understanding these components is essential for anyone involved in the cement manufacturing industry.