What are the mechanical devices used in mining What is the role of each

Time:12 September 2025

Mining is a complex industry that relies heavily on mechanical devices to extract, process, and transport minerals and ores from the earth. These devices are crucial for efficient operations, safety, and productivity. This article explores the various mechanical devices used in mining and their roles.

1. Excavation Equipment

Excavation equipment is essential for removing overburden and extracting minerals. These machines are designed to handle large volumes of material efficiently.

1.1. Dragline Excavators

- Role: Used for surface mining operations to remove overburden and expose mineral deposits.

- Functionality: Draglines have a large bucket suspended from a boom, which is used to scoop up material and deposit it elsewhere.

1.2. Shovels

- Role: Primarily used for loading minerals onto transport vehicles.

- Functionality: Equipped with a large bucket that can scoop and lift material, shovels are pivotal in both surface and underground mining.

1.3. Bucket-Wheel Excavators

- Role: Used for continuous mining operations, particularly in coal and lignite mining.

- Functionality: These machines have a rotating wheel with buckets that scoop material as the wheel turns.

2. Drilling Equipment

Drilling equipment is used to create holes for blasting and exploration.

2.1. Rotary Drills

- Role: Used for creating blast holes in open-pit mining.

- Functionality: Rotary drills use a rotating drill bit to penetrate rock formations.

2.2. Percussion Drills

- Role: Commonly used in underground mining for drilling blast holes.

- Functionality: These drills use a hammering action to break rock apart.

2.3. Diamond Drills

- Role: Used for exploration drilling to obtain core samples.

- Functionality: Diamond drills use a diamond-tipped bit to cut through rock and retrieve samples.

3. Crushing and Grinding Equipment

Once minerals are extracted, they need to be processed to separate valuable components.

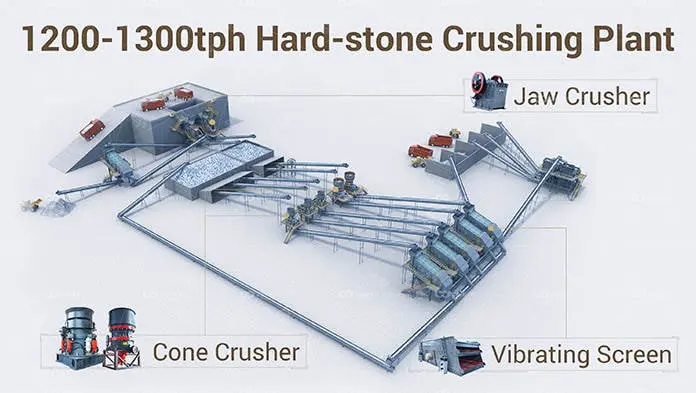

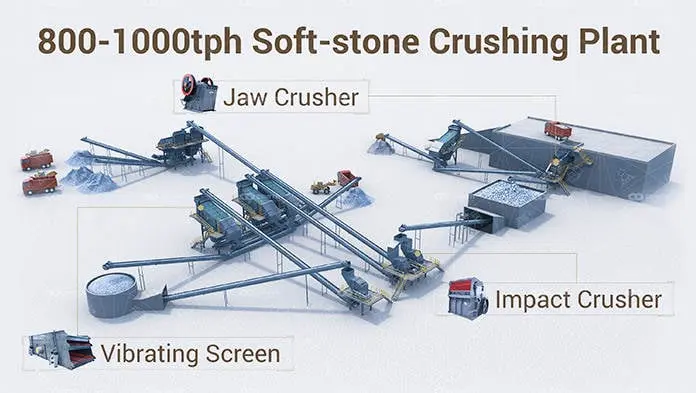

3.1. Jaw Crushers

- Role: Used to crush large rocks into smaller pieces.

- Functionality: Jaw crushers use compressive force to break down materials.

3.2. Ball Mills

- Role: Used for grinding crushed materials into fine powder.

- Functionality: Ball mills consist of a rotating cylinder filled with balls that grind the material inside.

3.3. Cone Crushers

- Role: Used for secondary crushing after jaw crushers.

- Functionality: Cone crushers use a rotating cone inside a stationary chamber to crush materials.

4. Material Handling Equipment

Efficient transport of materials is crucial in mining operations.

4.1. Conveyor Systems

- Role: Used to transport bulk materials over long distances.

- Functionality: Conveyor belts move materials from one location to another, reducing the need for manual transport.

4.2. Loaders

- Role: Used for loading materials onto transport vehicles.

- Functionality: Loaders have a front-mounted bucket that can scoop and lift materials.

4.3. Haul Trucks

- Role: Used for transporting large volumes of material from the mining site to processing facilities.

- Functionality: These trucks are designed to carry heavy loads over rough terrain.

5. Safety and Monitoring Equipment

Safety is paramount in mining operations, and various devices are used to ensure worker safety and monitor conditions.

5.1. Gas Detection Systems

- Role: Used to monitor hazardous gases in underground mines.

- Functionality: These systems detect gases such as methane and carbon monoxide to prevent accidents.

5.2. Ground Control Systems

- Role: Used to monitor and stabilize rock formations.

- Functionality: Ground control systems include rock bolts and mesh to prevent collapses.

5.3. Remote Monitoring Systems

- Role: Used to track equipment performance and environmental conditions.

- Functionality: These systems provide real-time data to optimize operations and enhance safety.

Conclusion

Mechanical devices play a critical role in the mining industry, from excavation and drilling to processing and transportation. Each device is designed to perform specific tasks that contribute to the overall efficiency and safety of mining operations. Understanding the function and role of these devices is essential for anyone involved in the mining sector.