What are the pre-crushing equipment in a cement mill

Time:18 September 2025

In the cement manufacturing process, pre-crushing equipment plays a crucial role in preparing raw materials for further processing in the cement mill. This article provides a comprehensive overview of the various types of pre-crushing equipment used in cement mills, their functions, and their importance in the cement production process.

Importance of Pre-Crushing Equipment

Pre-crushing equipment is essential in the cement production process for several reasons:

- Size Reduction: It reduces the size of raw materials, making them suitable for grinding in the cement mill.

- Efficiency Improvement: By reducing particle size, pre-crushing equipment enhances the efficiency of the grinding process.

- Energy Savings: Smaller particles require less energy to grind, leading to reduced energy consumption.

- Quality Control: Consistent particle size distribution ensures uniformity in the final product.

Types of Pre-Crushing Equipment

Several types of pre-crushing equipment are commonly used in cement mills. Each type has specific features and benefits that make it suitable for particular applications.

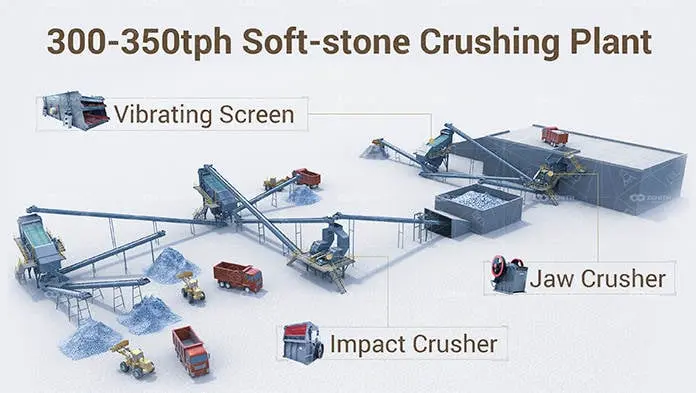

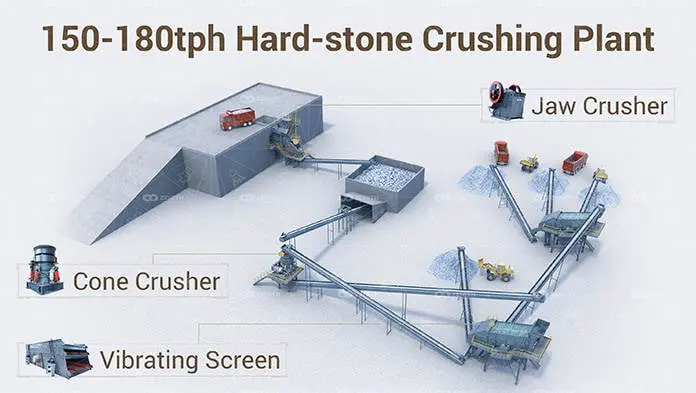

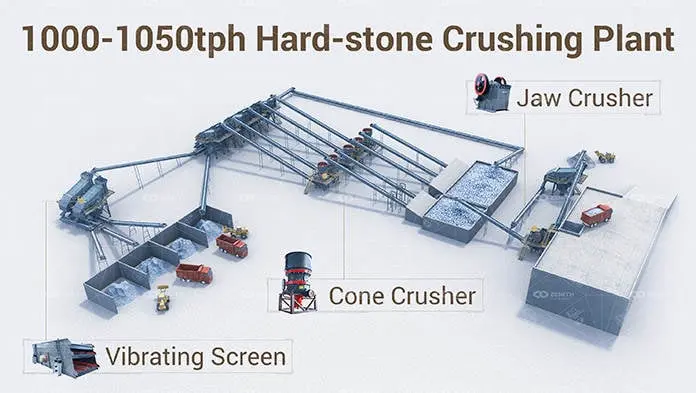

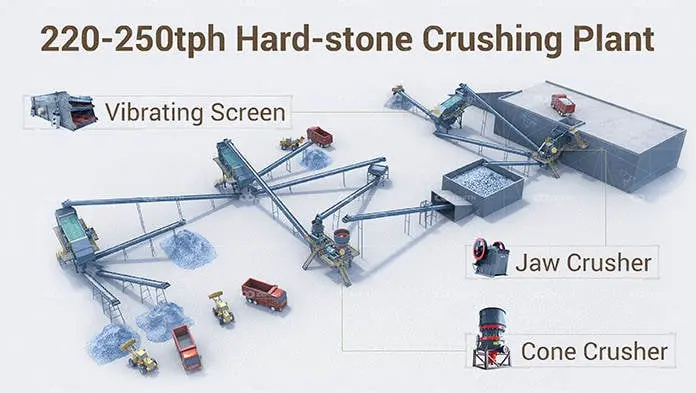

1. Jaw Crushers

Jaw crushers are widely used for primary crushing of raw materials. They operate by compressing the material between a fixed jaw and a movable jaw.

– High crushing ratio

– Simple structure

– Easy maintenance

– Suitable for hard and abrasive materials

– Used in the initial stage of crushing

2. Impact Crushers

Impact crushers utilize impact force to crush materials. They are ideal for materials with less hardness and are often used for secondary crushing.

– High reduction ratio

– Ability to produce a uniform particle shape

– Suitable for medium-hard materials

– Used in secondary crushing stages

3. Cone Crushers

Cone crushers are designed for secondary and tertiary crushing. They crush materials by squeezing them between a gyrating spindle and a concave hopper.

– High efficiency

– Consistent product size

– Suitable for medium to hard materials

– Used in secondary and tertiary crushing stages

4. Hammer Mills

Hammer mills use rotating hammers to crush materials. They are versatile and can handle a variety of materials, including softer ones.

– High capacity

– Ability to produce fine particles

– Suitable for soft to medium-hard materials

– Used in both primary and secondary crushing

Selection Criteria for Pre-Crushing Equipment

Choosing the right pre-crushing equipment depends on several factors:

- Material Characteristics: Consider the hardness, abrasiveness, and moisture content of the raw materials.

- Capacity Requirements: Determine the required throughput to meet production demands.

- Particle Size Distribution: Ensure the equipment can achieve the desired particle size for efficient grinding.

- Operational Costs: Evaluate energy consumption, maintenance needs, and overall operational costs.

- Space Constraints: Consider the available space for installation and operation.

Conclusion

Pre-crushing equipment is a vital component in the cement manufacturing process, providing the necessary size reduction and preparation of raw materials for efficient grinding in the cement mill. By understanding the different types of pre-crushing equipment and their applications, cement producers can optimize their operations, improve efficiency, and reduce costs. Proper selection and maintenance of these machines ensure a smooth and effective production process, contributing to the overall quality and consistency of the cement produced.