What is the process for mining manganese ore

Time:12 September 2025

Manganese is a critical mineral used in steel production, battery manufacturing, and various industrial applications. The mining of manganese ore involves several stages, each of which is crucial for the efficient extraction and processing of this valuable mineral. This article outlines the comprehensive process of mining manganese ore, from exploration to processing.

1. Exploration and Prospecting

The first step in mining manganese ore is exploration and prospecting. This phase involves:

- Geological Surveys: Conducting detailed geological surveys to identify potential manganese deposits.

- Sampling and Analysis: Collecting rock samples and analyzing them to determine the concentration of manganese.

- Geophysical Methods: Using geophysical techniques such as seismic, magnetic, and gravity surveys to map subsurface structures and identify ore bodies.

2. Site Preparation and Development

Once a viable manganese deposit is identified, the next phase is site preparation and development:

- Land Acquisition: Securing legal rights to the land where the manganese deposit is located.

- Environmental Assessment: Conducting environmental impact assessments to ensure sustainable mining practices.

- Infrastructure Development: Building necessary infrastructure, including roads, power supply, and water facilities.

3. Mining Methods

The choice of mining method depends on the depth and concentration of the manganese ore. Common mining methods include:

3.1 Open-Pit Mining

- Excavation: Removing overburden to expose the ore body.

- Drilling and Blasting: Using explosives to break up the ore for easier extraction.

- Loading and Hauling: Transporting the ore to the processing plant.

3.2 Underground Mining

- Shaft Sinking: Creating vertical shafts to access deep ore bodies.

- Room and Pillar: Extracting ore while leaving pillars to support the mine roof.

- Cut and Fill: Removing ore in horizontal slices and filling the voids with waste rock.

4. Ore Processing

After extraction, the manganese ore undergoes processing to increase its manganese content and remove impurities. The processing steps include:

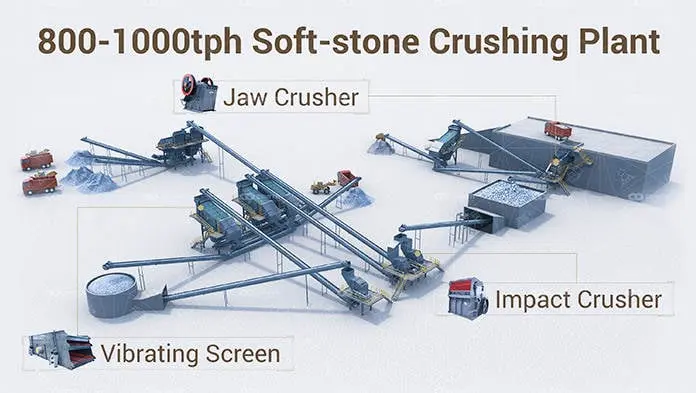

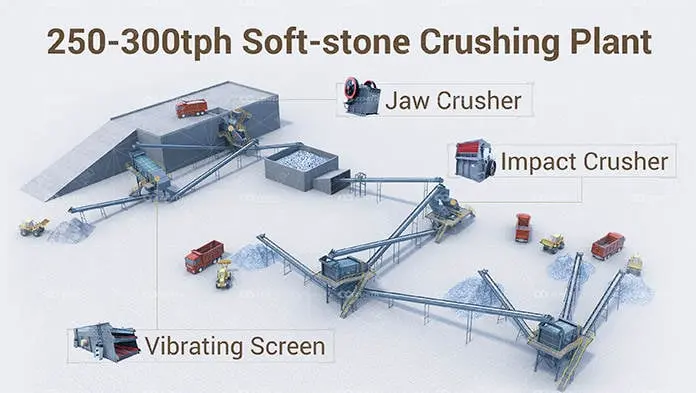

4.1 Crushing and Screening

- Primary Crushing: Reducing the size of the ore using jaw crushers.

- Secondary Crushing: Further reducing the ore size using cone crushers.

- Screening: Separating ore particles by size using vibrating screens.

4.2 Beneficiation

- Gravity Separation: Using jigs and shaking tables to separate manganese from waste based on density differences.

- Magnetic Separation: Employing magnetic fields to separate magnetic manganese minerals from non-magnetic waste.

- Flotation: Using chemicals to selectively attach manganese particles to air bubbles and float them to the surface.

5. Smelting and Refining

The final stage involves smelting and refining to produce pure manganese:

- Smelting: Heating the ore in a furnace to reduce it and separate manganese from other elements.

- Refining: Purifying the manganese through electrolytic or chemical processes to achieve desired quality standards.

6. Environmental and Safety Considerations

Manganese mining must adhere to environmental and safety regulations to minimize its impact:

- Waste Management: Proper disposal of tailings and waste rock to prevent environmental contamination.

- Dust and Emission Control: Implementing measures to control dust and emissions from mining operations.

- Worker Safety: Ensuring safe working conditions through training and the use of personal protective equipment (PPE).

Conclusion

The process of mining manganese ore is complex and involves multiple stages, from exploration to refining. Each step is essential to ensure the efficient and sustainable extraction of manganese, which is vital for various industrial applications. By adhering to environmental and safety standards, the mining industry can minimize its impact and contribute to sustainable development.